I have an issue with my 80w Red and Black 6090 laser.

Just recently I have recalibrated the axis (and they ware within 0.1mm which I would probably consider acceptable with kerf etc), and tightened the belts, yet when I run jobs, particularly with small cuts, and it seems mainly curved shapes, the start/stop points don’t always line up properly.

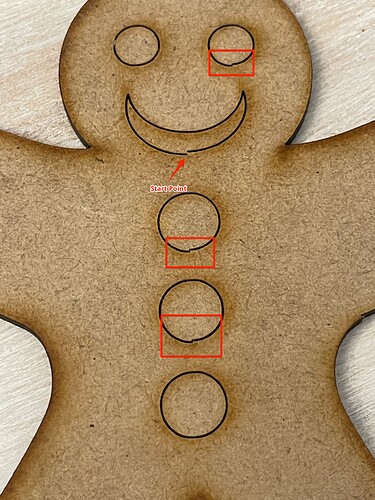

I’ve included an image showing this - as you can see in the gingerbread man, his smile starts in the bottom middle, and the start/end do not line up, nor do some of the circles on the body (his buttons). Small circles (such as the hole in a tag) look kind of squashed as well. Occasionally on a 30mm circle there is a tag at the start/stop point where it hasn’t cut through, but not really a pronounced step where it has shifted/offset.

Am I missing something here? I suspect that given the shift appears to be vertical this is maybe an issue with the Y axis but those belts are probably the tighter out of the X and Y belts (the X belt I could twist a few times easily, the Y not so much, maybe 3/4 to 1 whole twist at best, and thats getting difficult).

I don’t think this is a Lightburn issue, as I ran a small keytag in RDWorks over USB (with lightburn I use ethernet, but I always send the file and run from the controller, however it is the same if I run from the software or the controller), and the hole cut looks a little squashed as well.

Thanks for any assistance - it is greatly appreciated!

PS this is a somewhat new issue I believe, but I’ve made no changes in term of the hardware or software.