Oh yes, the annoying section of lightburn. I will get you the $$ data.

I constantly have this section popup when any of my projects end forcing me to have to go back and click back into the cut section where I wish it would stay. The console has been nothing but a pain for me so I will be glad if it yields something positive.

Sure, so there is a pot on most models, mine is a digital interface and there you can control the power setting or max power and allow the software to utilize a percentage of it, or at least that is what seems to happen.

I am curious how long did it take? I too can slow things down and use less power but why? My goal is to get the project done as fast as possible without sacrificing quality. So if I can run the machine at a higher laser output and gain speed then that’s a perfect trade to me. Is there something I am missing to why that’s not a good process?

Again thanks for your insight!

Well, there is nothing wrong with the way you look at it. I also try to drive as efficiently as possible, but when you reach a limit where it all knocks and almost falls apart, then the limit is exceeded, in my opinion and an original K40 does not survive in the long run to be “stressed”.

I have not noted the time, nen think it was about 4 min per image.

I am also convinced that over one whose speed you lose quality.

can you try to do a little test engraving where you have set your system to mm / min in the settings and report back how fast you can drive without it “hurting”?

… And type $$ in the console and see what value $110 and $110 is set to

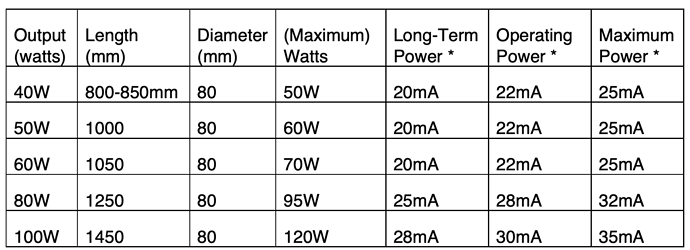

I am totally happy slowing down or decreasing power if that’s the right call. I was under the impression that 20mA was the safe top end of the stock K40 tube so that’s where I set my max.

It’s rare that I get anywhere close to that power level in normal use.

My cuts on 3mm ply is set to 10mA at 10mm which is a slight bit of overkill. When engraving I like to get down between .5mm - .75mm in depth.

I would assume my $110 is set to stock settings as I have never messed with anything to do with $$. I will check my shops light burn after breakfast (7:40a) here and the family and I enjoy a slow paced Sunday. The shop is outside so it will be a bit till I go out there.

Is the $$ the smoothieware config, I am not sure what data that is?

No forget it, these are gerbil commands / setup, it is not suitable for smoothieware. I do not know how your values are stored or how to adjust them in smoothieware. (sometimes I am blind with the laser eye)

At https://gist.github.com/nuess0r/1e19fe7ac8723345e31a096a602a407bare standard settings for a K40 and they look reasonably similar to those from the gerbil.

What I was interested in is whether your settings in LigtBurn are not slowed down by the value that is in your machine setup and you do not actually run 250 mm / sec. I use completely different speeds like you. (of course after I have converted from mm / s to mm / min)

Power, I have always understood that 16 mA should be max for a standard Chinese “40” Watt tube.

How long did it take you to engrave the test file that you sent to me?

I went to the link but got a 404 error?

I never knew that 16mA was the max. I am prepared to buy a new rated tube if need be. In the meantime I will make an effort to keep it below 16mA.

As to time… well I have never really clocked it. I use Lightburn to tell me how long it’s going to take and I set an alarm and return when the alarm goes off. Most everything I do takes 30min - 2hours 30mim so I tend not to stick around unless I am troubleshooting or testing.

I will run that file I sent you and tell you how long it took.

So I went out to burn and time it and now some other goofy thing is going on. No matter where I put the object in the project it will only trace it near the left corner.

I am so done with this “upgraded” processor and software I am ready to go back to the old processor. Yes the software is better but all the issues I have now just don’t seem worth it. It’s like being a developer for a new product vs something that should be pretty plug and play tried and true. I keep getting servos that whine as if they are being stopped yet they are not blocked and smooth, constantly has start up issues where I have to restart because of servos, now there is this software issue. I’m pulling my hair out and have been for two month and I just want to run one thing many times and be done.

Sorry to vent just done and tons on my plate where I don’t have time ti beta test. I expect some things like the power spike that was causing missed steps and distorting my runs but hardware that doesn’t work and now software issues grrrrrr.

It’s not good to hear about all your problems, but if it’s something important you need to produce, go back to a well-functioning version of LightBurn. Be a little patient, it is after all the best laser software on the market and I think the people from LB are running at high pressure to solve the problems.

you are lucky, on a my old standard power supply there is no potentiometer unfortunately, I have always wanted to down-regulate my power supply so I can use the right scale from 1 to 100 in LightBurn, but it does not work.

It depends how you’ve wired it.

I take it out of the loop and let Smoothieware control the upper limit. You can’t over-drive the tube that way.

No forget it, these are gerbil commands / setup, it is not suitable for smoothieware. I do not know how your values are stored or how to adjust them in smoothieware. (sometimes I am blind with the laser eye)

At https://gist.github.com/nuess0r/1e19fe7ac8723345e31a096a602a407bare standard settings for a K40 and they look reasonably similar to those from the gerbil.

What I was interested in is whether your settings in LigtBurn are not slowed down by the value that is in your machine setup and you do not actually run 250 mm / sec. I use completely different speeds like you. (of course after I have converted from mm / s to mm / min)Power, I have always understood that 16 mA should be max for a standard Chinese “40” Watt tube.

How long did it take you to engrave the test file that you sent to me?

22mA for an 80mm/800mm tube. but it won’t live long at that power.

20mA is the usual upper limit for reliability, but he 50mm tubes are pushing it at that power.

It’s very smart, I do not have this option with my Mini-Gerbil.

I also know this table but the described 40Watt tube is a real 40Watt tube, K40 is delivered with 700mm in length and is only a max 30-35 Watt tube. Here, max.16-18 mA is more recommended.