I have an Omtech 60 watt machine, which I got in November. I use 4-6 hours/day, 4-5 days per week. For the vast majority of my projects, I use 3-3.2mm Baltic Birch ply, and everything works fine. I started an elaborate “3D” etching with an irregular cut line in 1/4" baltic birch. The lens had just been leaned before I ran the project. The etched image turned out perfect but cutting it out was impossible.

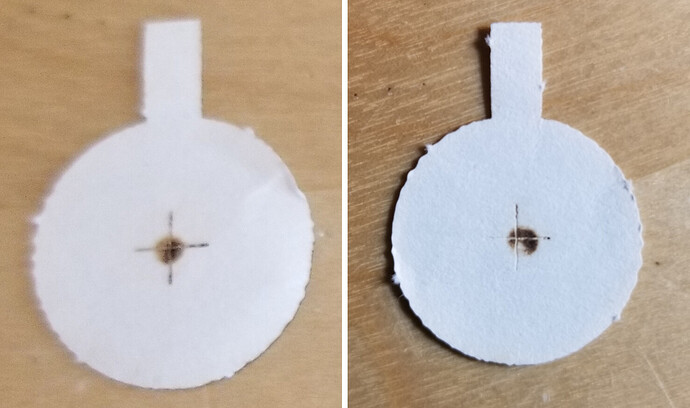

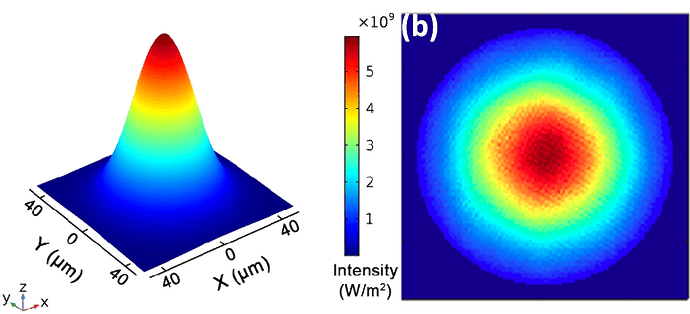

I will preface by saying that speed is mm/sec, power is %. Omtech suggests in their manual for 1/4" set speed at 6 and power at 32. I did this but didn’t cut through. I ran the cut again, 2 more at the same speed an power, still wouldn’t cut through. I changed speed to 4 and power to 45 for 2 passes, still wouldn’t go through. Finally, I upped it to speed of 4 and power of 70. Still wouldn’t go through.

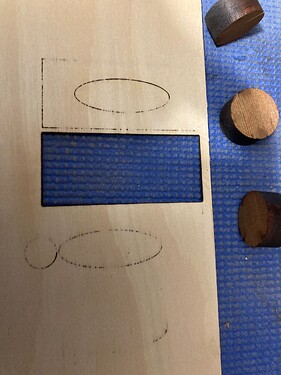

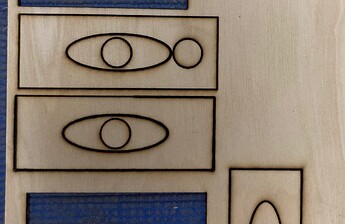

I checked my mirror alignment and it’s perfect. I cleaned the lens which by this time was filthy and proceeded to try some tests on the same material. Same results but now instead of a fine cut line I get a very wide burn line.

I’m clueless! I’m asking Omtech the same question.

Any ideas?

Dale