Hi there,

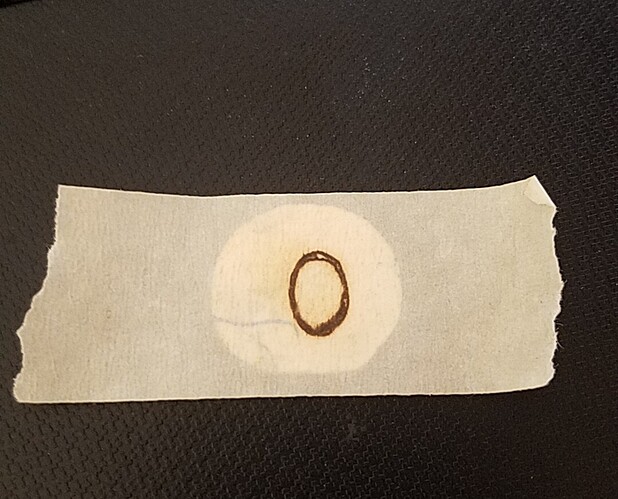

It hasn’t engraved right for a week. So i went to realign it. I taped the second mirror, nothing was visible on the tape. So i taped the first mirror, this is what i get.

what do you think the issue is?

Ps: When i first got it, it burned a hole out of the tape and cardboard.

Thank you.

If this is right out of the tube and not hitting a mirror etc then you have a bad tube. Back in the old days of flowing gas lasers I could align the front and rear mirrors in the tube to get the beam mode correct. What you have is a misaligned front and rear optic in the tube and these are not adjustable in sealed gas tubes.

I have seen this many times when I was a Field Engineer when tube optics where bad. or.misaligned.

The front and rear tube mirrors have to be co planar to each other pretty much perfectly to get TEM 00 or the typical round spot. If they are not both perfectly parallel to each other then you get weird beam modes or simpler…wonky laser spots. I see this is right out of the tube and not passing through anything so…tube issue. You might want to take a peak at the output coupler…basically the lens out the tube front and see if you can see anything burnt on the outside but I doubt it. Laser off obviously.

https://en.wikipedia.org/wiki/Transverse_mode

@shughey, such a great answer I felt compelled to reply in addition to the  and

and  I already marked your post with.

I already marked your post with.

Could you explain why it worked great for the first 3 months? It is a RECI. Thank you.

Could you explain why it worked great for the first 3 months? It is a RECI.

Not really……could be a failed mirror which kind of looks like….by that I mean burned. There are multiple things that can cause a failure…defective optics…air bubbles in the tube water cooling jacket that collect at the output mirror can cause them to fail….any unknown manufacturing defect etc.

I can’t say what caused it although I have never had a mode like that from an improperly aligned mirror and actually they are potted in place so I would guess more a failed optic.

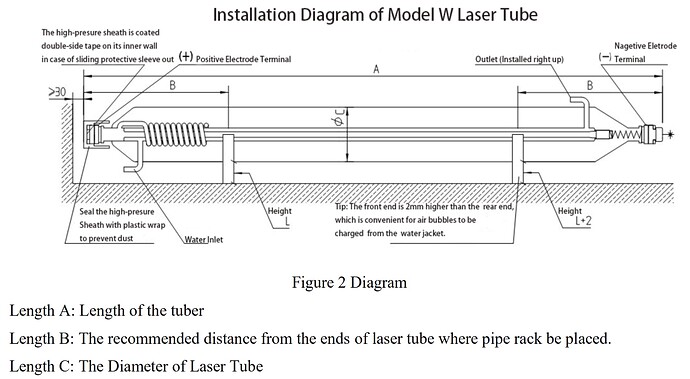

If I had to guess and this is just a guess…looks like the front mirror is burnt…guess that maybe there was air trapped in the front of the tube where the water exits and the mirror burnt. The water outlet tube on the laser needs to be at the top of the tube or off to an upper side but not at the bottom preferable so air can escape when you first put water in.

Anyway the beam mode is hottest in the center and cooler towards the edges, so to speak, and common to burn the center areas first. But this is just an educated guess.

If you take the tube out you can look through the front optic and might see a burnt optic….or not.

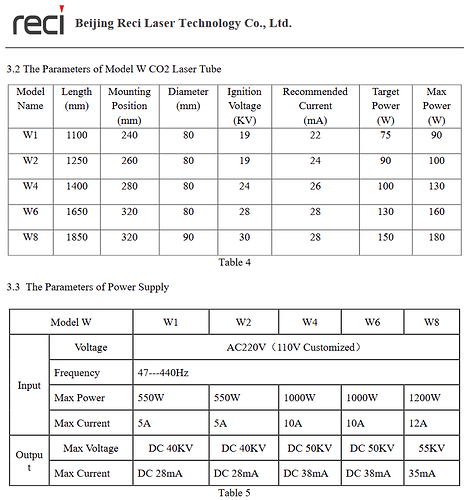

I am assuming you have a W series Reci.

One of the culprits could be over-driving the tube. Do you have an ammeter in operation and have you calibrated your laser PSU so that a layer set to 100% power does not exceed 28 mA current in the laser tube? Long-term current for a W6 or W8 is 26 mA . This means you should never drive the laser tube above 26 mA (even if its 28 mA) on a long running job (long, slow, continuous material cuts for example).

*** The long-life ~8,000 working life is achieved by not running the laser tube over 24 mA. ***

Another problem could be ineffective water cooling. What chiller do you have in service?

I have this on my machine and I have never seen it go beyond 20.

This is the water is the chiller I use. I pinched both hose and can fill the water flowing and 2 twice in the last 3 month, the machine didn’t start the job because the chiller wasn’t on, so I am pretty sure it is working.

Also, I only did engraving since I got this tube.

Can i have a video on how to use an ammeter. Never measure it on the power supply or anything.

Thank you.

The tube is a W6 and the high temperature on the cooler is because I just turn it on.

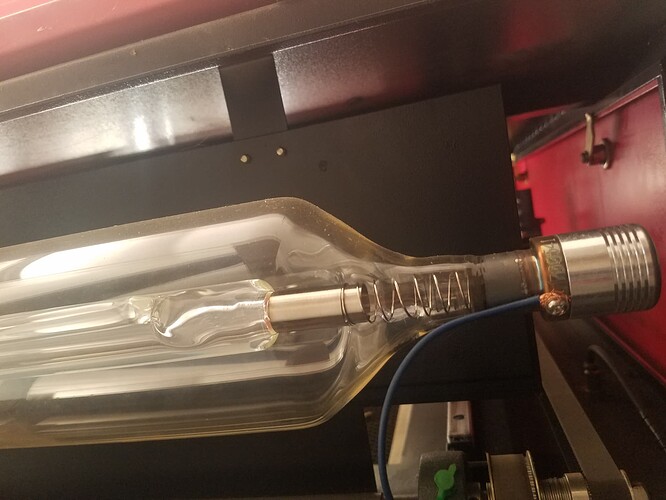

If you overdrive the tube many times you can look at the inner metal end ( the anode or Cathode ) and see if it is still silver colored or has turned like a goldish. This is inside the tube about and inch or two from where the output mirror is up front. Many times if someone cooks the tube this will turn color…so you can take a peak at that. Not a “fer sher” thing but if it is discolored then that is a tell.

What was your max % you engraved at. I mean if you never went above 50% lets say i would doubt you overdrove the tube unless there was a PWR supply issue…IMO.

Is this a tube you just installed recently…? I have installed many sealed tubes over the years and while not common I have had a few that were bad or went bad quickly…like a few weeks…it happens. Again not common but not unheard of. Never know…manufacturing defect…or hey it had to survive being shipped from China to the US to you…and not like anyone pays attention to… FRAGILE GLASS HANDLE WITH CARE

Normally 20% power, 80% speed but i had to up it to 30%max in the last month and still it wasn’t working right. Tube installed in the last 3 months and changed the power supply around a month ago.

Did you change the power supply because this issue popped up and thought that might be it…or basically why did you change it and was this issue before or after the supply change.

Irregardless the tube is bad though. I don’t think you did anything wrong per say…I mean 30 % is squat…you have a chiller…maybe if you were running at 80% or up for long periods without good coolant flow then maybe you buggered it up but I think you just got a bad tube.

Have you checked the end of the tube at the output mirror. Some of these have some sort of protective tube to keep smoke out or something weird. Can you see to the output mirror of the tube or is it too close to the first mirror. Sometimes these OM lasers have a panel on the side you can take off and shine flashlight and see.

Running out of possibilities though but you should inspect that optic on the tube

Change the power supply because i was having issues with horizontal lines appearing on in my engravings then found out it was the ruida controller (have to start the job on the controller not the computer). i can screw off the output mirror and check it out. Tube still under warranty. will ask for a replacement. but it is good to be sure the problem is not on my side

Definitely check that lens… before sending it back. The actual lens or output coupler is potted in place but sometimes they have that weird protective thing on Reci tubes I have seen in their adds. I don’t have a Reci I just have seen the pics…so not sure what it is exactly but make sure nothing is burnt in or on it

Per Reci:

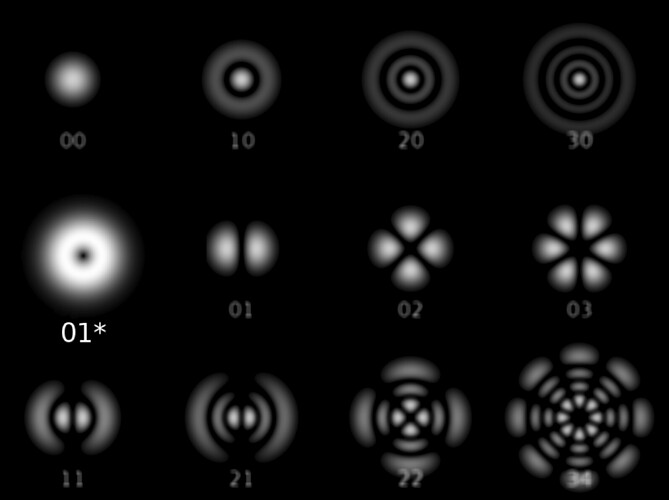

What you appear to be outputting is a TEM0i* mode pattern:

The Wiki page on this describes this as being the donut mode and caused when you have a combination of two of those modes in that middle row there.

I am curious, does the system perform at a degraded level (not as powerful)?

Yes, laser not as powerful. I first thought it was an alignment problem, so when i am checked the alignment on the second mirror, i couldn’t see any burn on the tape. so went to align the first mirror, got that empty circle

Isn’t really TEM 01 actually. I have seen TEM 01 before on lasers and it is a donut…not a circle. In any laser beam there are energy streams it is not one uniform energy stream. In TEM 01 the energy streams are strongest or more concentrated at the outer edge and gradually drop off to nothing in the center. Opposite of TEM 00 which is what you should have where energy streams are more concentrated towards the center and are slightly less concentrated at the outer edge. The TEM chart doesn’t show a cross section of the beam which would make more sense…basically like a CAT scan looking sideways at the beam verses the TEM chart is like looking right down the center.

Anyway…your mode is not right under any TEM chart…

I would feel 100% sure of sending it under warranty at this point. Just send it back

can a change in power supply affect the laser output?

It certainly could but I never seen it change the mode.