im going to use my thunder nova 35 100w to engrave a very large piece of acrylic that wont fit all the way on the bed. So im running practice pieces to trouble shoot. so i made myself a guide on the top left corner, cut with the laser at the very limit of the work area as a starting point. from here i am cutting a square, then repositioning against my guide making sure nothing moves or shifts, then engraving half of the square with a template made and positioned correctly in lightburn. After half is engrave all i do is rotate the square 180 degrees, and lined back up with the guide in the machine, rotate the other half of the design, and position in lightburn with the template i aligned the other half with. Then engrave and i still have a slight shift. im not seeing how this could happen. i have run 4 separate tests ruling out different things like if something is physically shifting in the machine which i have assured isnt happening. the way i cut the design in half in lightburn will match right up if centered on each other. i make sure im aligning each half on the frame/template in lightburn the same each time. im very confused. sorry for the long post and any ideas to try and help is extremely appreciated

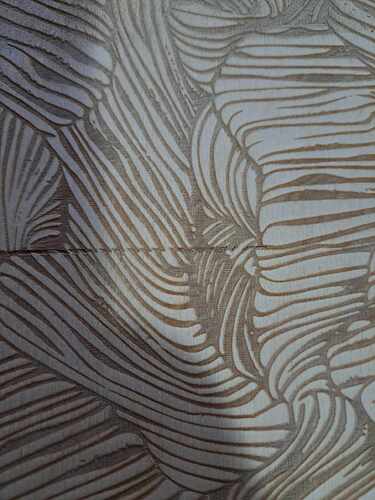

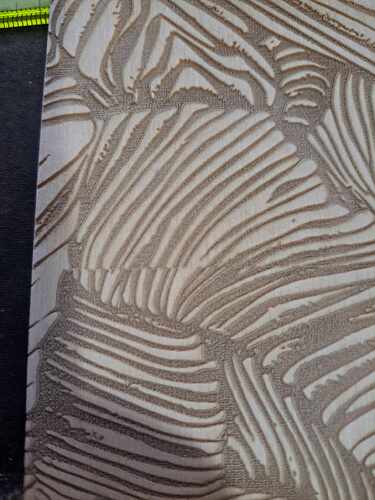

Please post pictures.

images are all posted now

Try using print and cut. Here is a video I made outlining the procedure to do just what you’re trying to do.

i will definitely give this a try and see if i can get the results im after

Your photos are of a funny looking type of acrylic…?

A couple things can cause this.

First is that when you flip something, it has to be exactly flipped across the image.

Another issue is the part locating mechanism or how you register the material in the machine.

Not knowing how large this is, it’s tough to determine how far off it is.

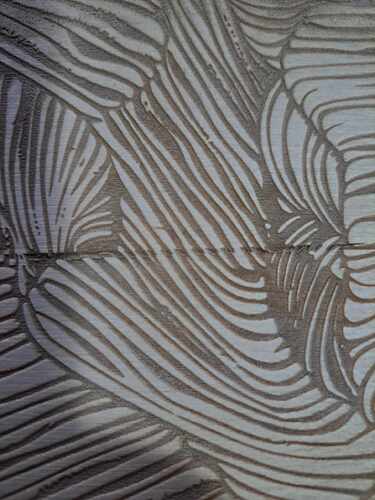

It looks to me as if it’s in the artwork because of how far it’s off, but difficult to tell.

![]()

thanks for the insight. its weird because the artwork will line up in lightburn. i know the laser is never going to be perfect but i figure in the right conditions if the machine cuts the piece and can perfectly engrave before its moved i figure it would at least be within the margin of error whoere you wouldnt see it unless looking very close if i keep the piece in the same lacation with guides and such

Some of your output looks correct and aligned. This would indicate, off hand, that it’s not being aligned in the jig holding it into position within the machine.

If it’s skewed any at all, that part won’t line up. If the artwork is correct, that only leaves how it’s positioned in the machine.

![]()

its not exactly a solution and i would still like to dig into this and see whats up and what can be fixed but for now i am going to use the rear passthrough so im only using one point of reference instead of trying to rotate the piece. im sure this will work fin and if it doesnt then ill know its an issue with the gantry system not being consistent which i doubt

just another update. i went down the rabbit hole and mathed out how to make an actually accurate side guide. with measurements accounting for the kerf and the exact distances to the actual edge of the work area the laser can reach. also added a “buffer zone?” of .25 inches so i can engrave right up against a perfect edge. hopefully this all makes sense and long story short i got it dead accurate so if i cut or engrave a 4 inch square in lightburn it will match up exactly where 4 inches is on the ruler i engraved on the guide. this took a hell of a lot more work than i initially thought to make it actually acurrate real world vs in lightburn.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.