just the grounds!! you might not need to, i have a slightly different circumstance and i had to. the directions are not very clear with the S9, and im still not sure if im getting full power at 100%, i have yet to measure it. Its a good little laser but if i had to get another it would be the dual 5W with the spot compression.

Also if interested and your cnc can do aluminum, i just designed and made an air assist nozzle for mine as well as some other changes. I can send you the .tap file if you want to try and make one. I am on round 2 as i wanted it more defined and pointed to match the small beam and penetrate into the cut .

Many electronics have split supplies. Meaning 12 volts, ground and a -12 volts or the possibility to have a 24 volt system. When I read your +12 volts and -12 volts, I was thinking a 24 volt system.

Most of us read -12 volts as 12 volts below ground. 12 volts and ground covers it…

Some of the answers, I think show signs of some confusion, that’s why I mention it…

Make sense?

For any system to ‘communicate’ the require a path there and back, in simple terms. So it’ real common to just tie the grounds together.

If your supply is only 12 volts and the other supply is 5 volts, you can probably tie them together. If these are actually - values, then you can not…

If you don’t own a voltmeter, buy one and learn the basics of it’s use. Can’t do without one…

Just don’t buy real cheap Chinese replacements.

That cost me another supply and a control board in an attempt to save a few bucks…

Good luck

![]()

Thanks Jack… I see where I was confusing giving the impression of 24v… ![]() I just meant + and - from a 12v supply.

I just meant + and - from a 12v supply.

I have all the grounds tied together for all the other kit like stepper drivers in a nice network of wires but they’re all 5v so it was making me uneasy no matter how much sense it made. Thanks for clearing it up.

Got you! still coming to terms with the fact that it’s ok to connect the grounds together ![]()

Yes, it was interesting reading about the potentially lower performance using a 5v PWM… even though the website shows that it works anywhere between 5v and 12v. It will be interesting to keep this thread updated so we can compare results.

I might invest in a new BOB that does 5v and 12v connections going forwards, but I’ve just dug the CNC out after 6 years and have other investments to make first so will give it a go with what I have first.

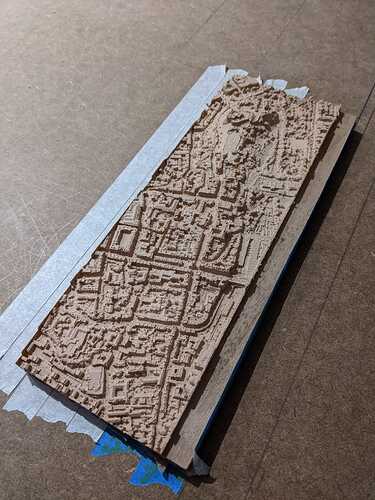

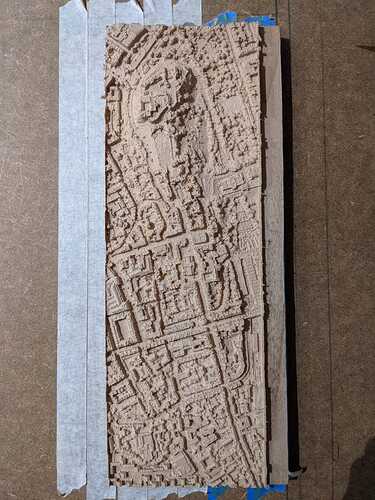

I haven’t attempted Aluminium yet but thanks for the offer! I’m guessing my machine would manage it… I over-engineered it in some ways ![]() I’ve been trying to refine carving wood so far (check out the Edinburgh Castle pics!)

I’ve been trying to refine carving wood so far (check out the Edinburgh Castle pics!)

Air assist is something I looked at seriously for the first time yesterday… I’m hoping to laser images onto reliefs so maybe not needed just yet?? I think that’s more for cutting right? The S9 caught my eye because of it’s fine beam I thought would do better quality ‘prints’.

I doubt that it would make a difference. The schematics I’ve seen just run the PWM through an optical isolator so any digital signal within the range specified should be fine.

I could tell from the conversation that it might be an issue. Thought I’d mention it when you stated you didn’t know much about voltmeters or electronics.

Don’t let it keep you up at night… we should all be in ‘learn’ mode…

If for nothing else it’s main function when engraving is keeping the lens clean. Not allowing debris to go back up into the lens. When you lase something, it has a tendency to be driven back towards the lens.

It’s also beneficial to remove debris off engravings… helps prevent staining…

Love it… How did you hold it down?

Good luck

![]()

Love it… How did you hold it down?

That’s a trick I’ve learned off Youtube… Stick masking tape to the bed and smooth it down… stick masking tape to the back of the workpiece and smooth it down… then use superglue to stick the workpiece to the masking tape on the bed… A scraper and a bit effort will get it off apparently - haven’t tried that bit yet ![]() but it seems a good way of doing things… better than clamps for sure.

but it seems a good way of doing things… better than clamps for sure.