Hey guys, I searched the forum but didn’t see anything about what I have going on. I bought a new 4 wheel rotary roller because the two bar ones don’t work well for tumblers. I’ve been having a lot of banding. Line interval: .8. Speed 5000 mm. 65% power. 10 watt atomstack. Belts seem tensioned correctly. I believe that I have the mm per rotation set correctly as well as the object diameter.

Don’t think this is the right catgory for this…

The 32dpi, might be an issue. I haven’t seen that pattern, but I usually use at minimum 254 dpi but I find that I have to go as high as 508dpi sometimes depending on the material.

The pattern of the lines seem to indicate the possibility of a mechanical issue such as debris.

Might add the unit for the speed /m, /s ? Assume it’s by the minute.

Have you done other items that are OK?

What type of rotary did you use?

![]()

It might be the wrong category I submitted it in a rush. The dpi would have to be wayyy higher than 254. I ran it at as a fill pattern and the software defaults 0.10 mm as a line interval and on my old roller I would use the default it worked well. I ran it .08 mm (317.5 lines per inch) and still have banding.

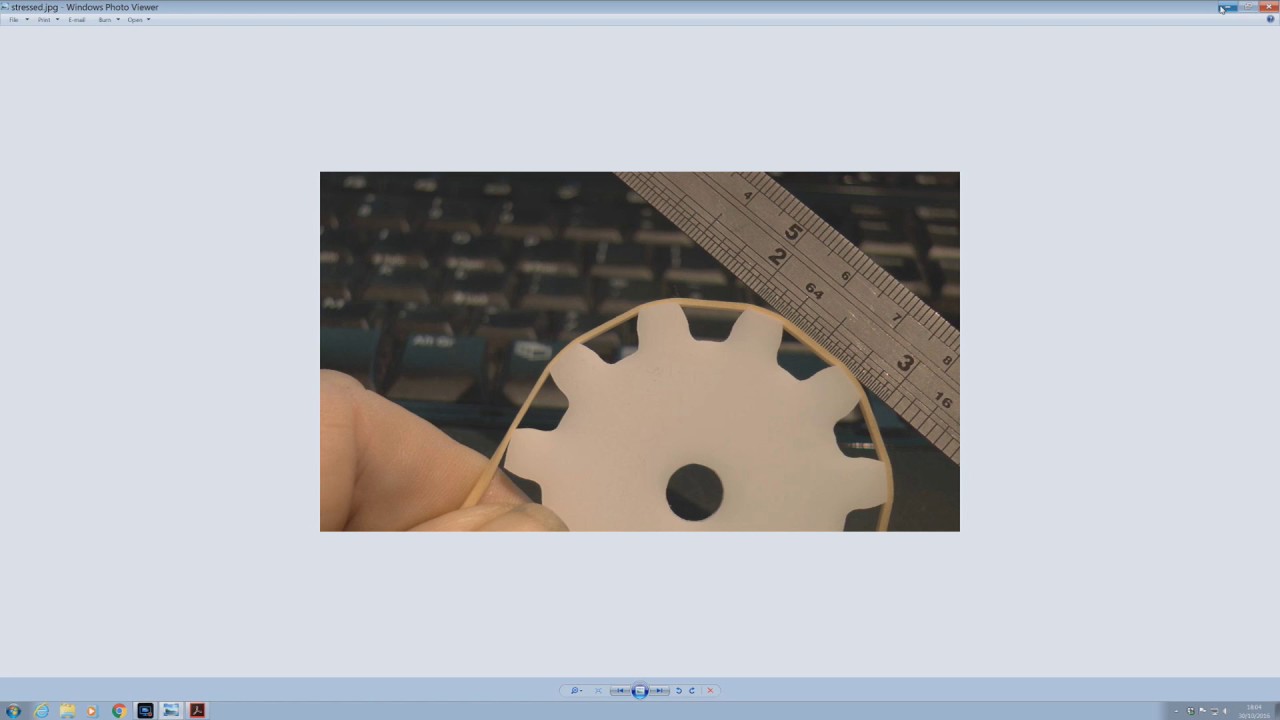

Is it possible that my mm per rotation is wrong? I set it up so the big wheel made one rotation and turned around making another rotation stopping at the starting point. Should I set the rotation based on the cup itself? It’s strange that the lines are pretty consistently spaced telling me it isn’t the engraver.

The roller is a Vevor

Don’t follow you here.

I would think you would be fine with the 254 dpi (0.10mm line interval).

I doubt that. It’s easy the engrave a rectangle and measure the results…

I don’t use a grbl machine, so I’m not up on the settings.

A wheel rotary shouldn’t require any adjustments to the mm/rotation once it’s working. The driving wheel is moving the same as the Y carriage/table. This means the surface speed of the item will always be same for any sized object.

Not so with a chuck type rotary.

I’m not sure what to advise you at this point.

Maybe someone at @LightBurn can move it to someplace where it’ll get more ‘traffic’…

Good luck

![]()

Thanks for your help, I appreciate it. I’ll only be using a GRBL Machine as a primary for a little while I have a few co2 machines being shipped.

If you place the cup back on the rotary and move it by hand - does the vertical line spacing correspond (reasonably well) to the drive belt pitch?

Some belts produce a minor error in linear motion. The ones that do often have a minor bit of belt-lift as the belt tooth takes up on the leading or trailing edge of the sprocket. It can produce an error that looks uniquely like this.

I’ll have to look into it I’m currently backed up with cornhole boards and my machines are running almost 24/7. If this is the case is it fixable? Should I buy a new one? I haven’t gotten it yet but I know a client of mine is considering a massive order of cups and I haven’t really played with rotaries.

This is a video from Russ that explains the effect @JohnJohn has mention.

Might give it a look and see if the symptoms indicate this issue…

This was the fix… might not be applicable to you…

Good luck

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.