I’ve received the new laser I purchased. It’s a 90W RECI W2 laser. I initially thought I had bought the best, but now I think I might be one of the unlucky ones…

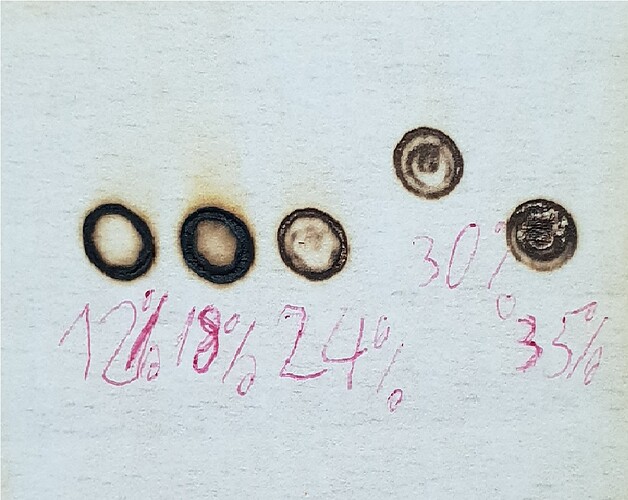

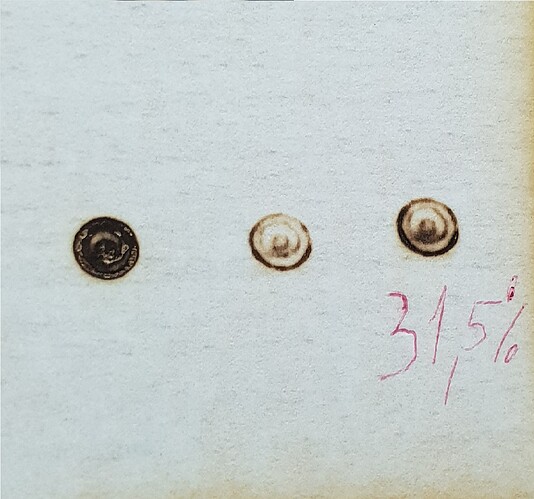

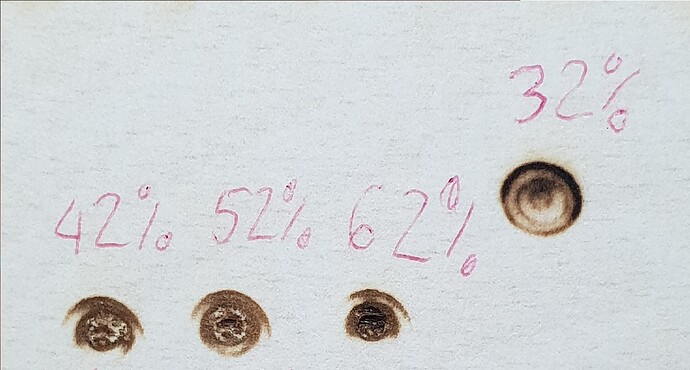

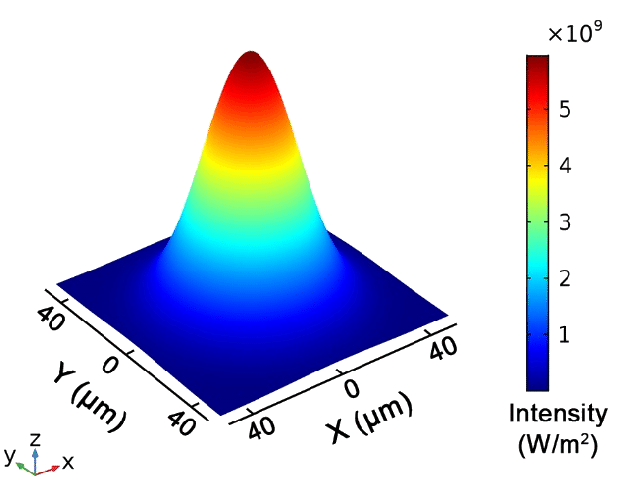

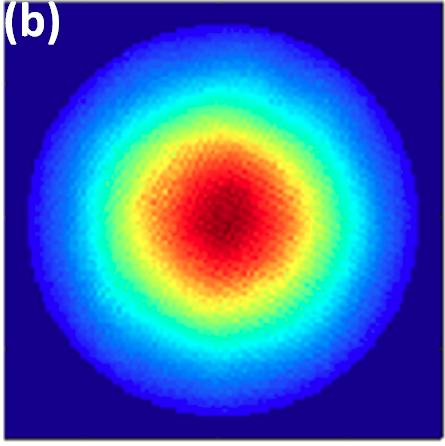

It turns out it has what I believe to be a defective laser beam, as it outputs a laser beam in the form of concentric disks (TEM20 ?). Please take into consideration that 64% is the max power that I can feed the tube with.

This happens at both low and high power (I read in this forum that it’s normal to produce these disks at low power, but in my case, it also happens at high power, although they are merged).

Can someone confirm if the laser is defective?

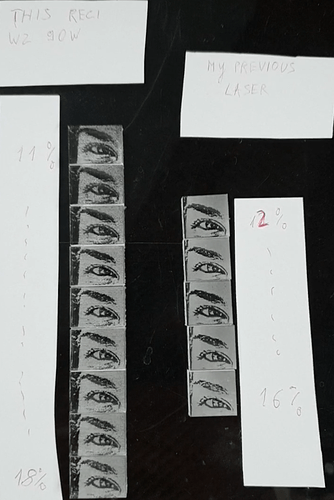

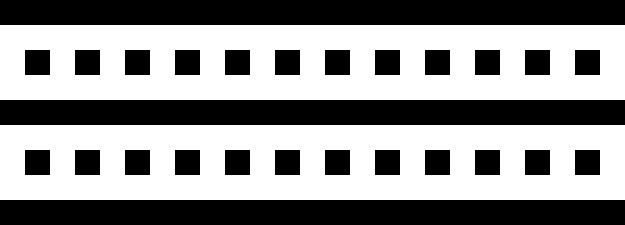

I’ve aligned the mirrors and it does focus on a point seemingly correctly, but it doesn’t have as much power as my previous tube. Before, I could cut a 5 mm thick acrylic with 23% power and 6 mm/s, while now it barely cuts it with 38% power and 6 mm/s. Additionally, the engraving quality on acrylic is terrible: the scan lines are interrupted (even when engraving at 17%), not all the details are visible in white… I believe it’s because the focused laser point isn’t of good quality.

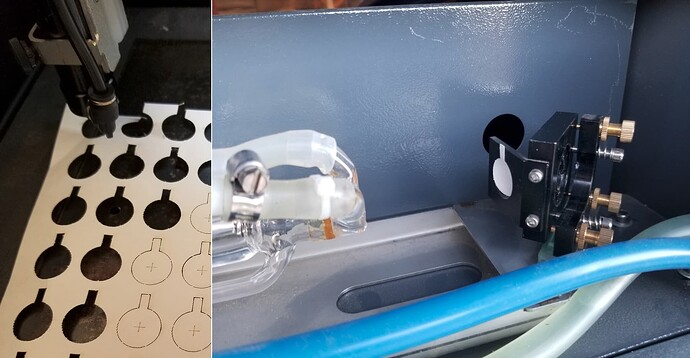

I have to mention that since the laser tube arrived first, I tested it right away (as if the product is defective, I need to report it within the first day of receiving it) using a black MYJG80W power supply, only doing a few pulses at low power (14% and 18%), and the result was the same.

Now that I’ve received the blue DY-13 power supply, I’ve tested again, and the results are what I’ve mentioned at the beginning of this post.

I’ve contacted Cloudray, and they keep repeating that it’s not recommended to use a power supply with more than a 20W difference because it could damage the laser tube. However, there’s not more than a 20W difference, at most it’s 10W, or up to 20W if we consider peak power. And to be honest, I don’t think that a few pulses from the MYJG80W can damage this 90W tube…

Can someone advise me on how to proceed with Cloudray?