It’s because you used passthrough, I suspect - that means “do not resize, adjust, or touch - just threshold and send directly to the laser”. It is intended for images that were dithered externally using things like One-Touch, PhotoGrav, etc.

If you are sending a normal photo through LightBurn, what you did last is the best option. You can select the photo, right-click, choose ‘Show Properties’ and adjust Gamma (mid-tone curve), Brightness, and Contrast, as well as edge enhancement options there.

I removed the passthrough and from interface perspective it looked the same on the settings. Something was not taking the correct values I guess.

Pass through ignores the settings. That’s why they all get disabled, because they are not used.

That I get it, but even disabling it it was not working. Like in UI been disabled but not in reality. Will try to replicate later to see if I find what can be wrong

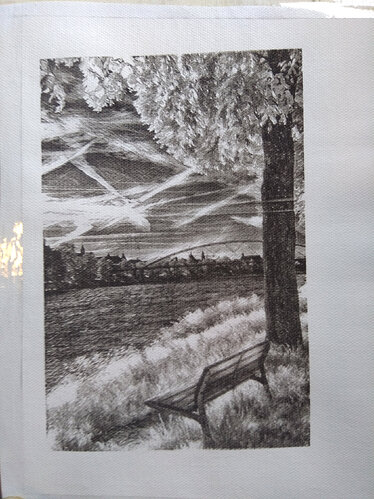

What a coincidence, I am writing a blog about how to dial in the engraving. It will be published within a day on awesome dot tech. I see you try to run the test pattern to determine the dot size which is a great starting point. Try to engrave the pattern at various focal points to find the best dot size. (Threshold or Grayscale setting at Speed 50mm/sec at 15-20% power)

Within k40 and a good quality lens you get about 250 to 350 dpi unless your picture is lower resolution.

Try Dither, at 127 DPI, at 70mm/sec with 14% power. Try another photo incase the image is just too low in resolution. Make sure over scanning is enabled to avoid jarred edges. Make sure that you have a sharp focus otherwise you won’t get it right. Let us know how it went!

Hopefully, this is OK, but I used James Deans video to set up my CNC as far as tuning. However Deans stuff is based on Grahams setup of laser and address just this type of stuff. Dean also has a video on setting up the laser. It’s worth a look, something may stick or fix an issue. Anytime you change material you will have to adjust the ‘tool’ (and/or machine) as with any ‘machining operation’. More powerful laser, different feed rates, different materials change feed rate. Also, keep in mind that the requirement of wide range of flexibility of configuration options makes most software like this difficult to learn. I was told it was a steep learning curve, but I didn’t imagine it to be an overhang. Have a 30 watt unit here, just can’t get it mounted yet… Hang in there I have no doubt you’ll get it.

Take care (0-0)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.