I have been using my ortur laser master with a 30w neje to print items. I found out , there is a new way of using decal cutter and laser to increase production sale. laser is great it very costly and demanding. the hours of getting thing it is time consuming.

- cut materials on laser is no-brainer. you need to be careful with the fume.

- laser can do much but it is always not reliable when it comes to do some work and color an items.

- laser you need a lot ventilation. All cost money to keep up.

Do not get make me wrong I like my laser machine. I will always use it for some work but not the all work.

a) since I start my business couple month ago.I find out by adding another piece of equipment beside the laser will help me increase sale, by using the same formula and the same software ligthburn to increase my production. the piece of equipment is a vinyl cutter machine. All my designs still done into ligthburn a software that I like so much and it is easy to use. it save me time and increase production.

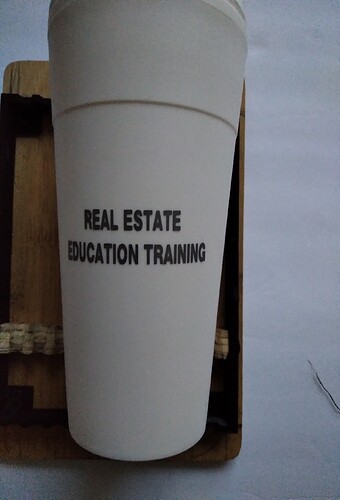

the laser will take time to burn or engrave 2 pieces of item and also I have to have my garage always open because of fume event I do have great ventilation for protection. now no more.A vinyl cutter do the magic trick for me. Now I have a lot of time to spend with my family and do some exercise during the day while all my work is done on time and ship out to customer. Please my work with the laser combine with a vinyl cutter. - I can make color pen with my vinyl cutter very fast and quick

- I do not have to worry about fume any more by using vinyl cutter

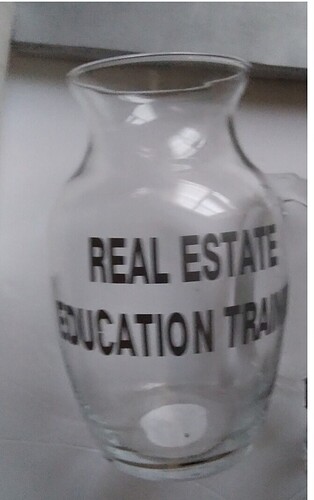

- I do not have to use a laser to etch a glass any more all done by vinyl cutter on the fly

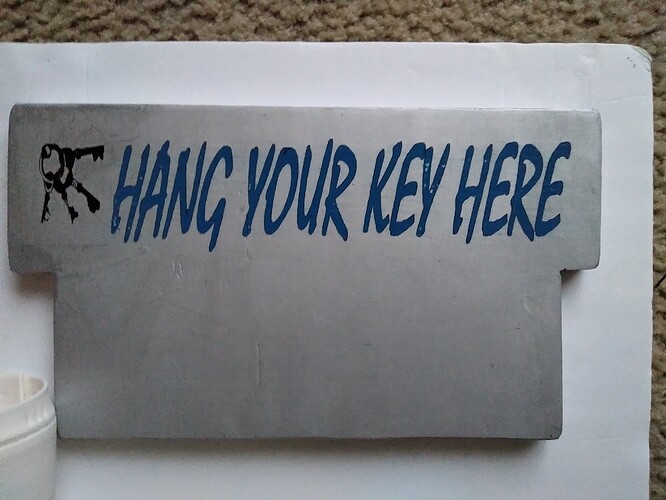

- a combination of laser and Vinyl cutter work. I take only 19 minutes usually on the laser it will take more 3 hrs plus. the key design was made on the vinyl cutter the rest was made with the laser printer. I made 4 for a customer. still have time to do some shopping to replenish my inventory for my next order.

I am curious now

I am curious now now I get what you mean.

now I get what you mean.