I have a Chinese Cam5 laser with a rudia 644xs controller that originally ran a 130w CO2 laser tube. Due to various reasons my Boss decided to downgrade to a 80W CO2 tube. with the higher tube the laser would fire at a minimum power of 7.5% and above. It now only fires at 25% and above. Is this normal? I get the feeling the laser should be able to fire at lower powers but I am not sure.

I was hired as a printer and had laser cutting thrust upon me as a secondary duty and am entirely self taught. so please explain with as much simple detail as possible.

Yes that’s normal. An 130W tube will probably have a bigger power supply unit than that which would be optimal for a smaller (usually shorter) 80W tube. The trouble with using wattage for tube identification is similar to using speeds for car identification… sellers will talk about high wattages than engineers might as we have 2 values, an “agreed” power and a “peak” power… anyway…

130W tubes are much more expensive than 80W tubes so I guess this is a “cost saving” of some sort? You could find the High Voltage PSU (usually on larger machines this is at the back on the right side either accessible through a side or back door) and is usually a box (often black or blue or silver) about a ft long by half a ft wide with a red cable and a black cable coming out of it and 2 green connectors going into it. Often on the PSU there will be a sticker or similar with some information, such as the voltage of the PSU often as an R value or T value so, R100 or R150 or R80 or T150 or similar. Though sometimes manufacturers or suppliers peel that info off.

Personally I’d just live with it.

Did you change the PSU when you changed the laser?

Did you change any settings on the controller?

Yes the PSU was swapped with the laser tube. I did not switch any settings in the controller.

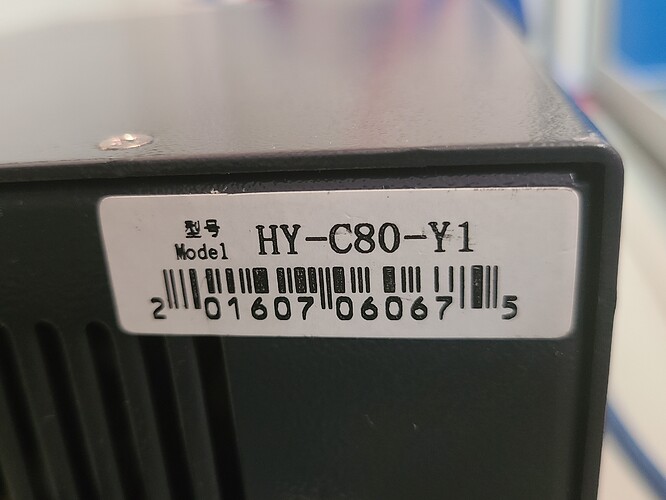

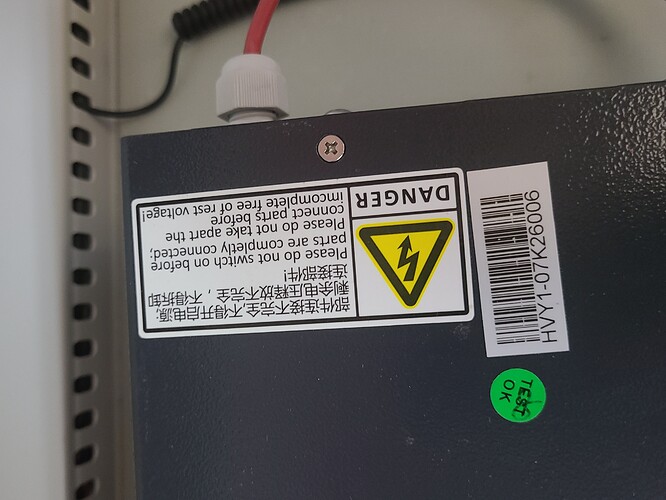

New power supplies were acquired with the new tubes, presumably they are for 80w use but I could not locate any of the sort of label you mention. It has a few barcodes and handful of “passed inspection” stickers. I can post pictures if they might be relevant.

(less cost saving and more my boss not knowing a thing about lasers and being sold on a more expensive model than was wise for our uses.)

Put the original psu back, there was no need to change it. A psu larger than your needs runs better than one that just meets your needs. Less strain, faster response.

You’ve replaced a working, calibrated unit with one that has unknown settings and capabilities. That it has no identifying marks says to me it’s a unit sold on price not capability.

Was the new psu calibrated by the installer? (That you need ~24% to fire makes my question moot)

The unit was mailed to us, we did the replacing ourselves. The same with the tubes. I was not the ordering party so I am not sure about any details about the units on that end. And from what my boss said, it was just the tag along psu they told him to buy when he purchased the new tubes.

So, I’m pretty sure then that the psu is uncalibrated. Is this something I can calibrate myself?

I doubt if I would be able to convince my boss to change back to the old units. I would need his go ahead to make any hardware changes like that to the machine.

I did find a sticker that seemed to have more info about the unit on the second psu. The machine is double headed, I had previously only closely examined one of the units for my earlier answer so I missed this one ( the laser power sticker).

25% on an 80 watt tube is not normal. Mine is around the 11% range for_reliable_output. I know others have stated their tube requires even less.

Tell your boss that he needs to pay a tech, not be a cheap assed waster

Well a big part of my worth at my job is working through things like this and making them function. And I rather like having a pay check. Before I started this job the machine had sat for 2 years with no one knowing a thing about running it. I was assigned to making it serviceable when not doing my primary job. So I am entirely self taught in everything to do with running laser (These forums helped a whole lot. Thanks guys). So in any case, my own gripes about it aside.

Well a big part of my worth at my job is working through things like this and making them function. And I rather like having a pay check. Before I started this job the machine had sat for 2 years with no one knowing a thing about running it. I was assigned to making it serviceable when not doing my primary job. So I am entirely self taught in everything to do with running laser (These forums helped a whole lot. Thanks guys). So in any case, my own gripes about it aside.

I was able to get ahold of the service line at Cam 5 and work things out. The PSU is functioning within the advised range for the tube I have so everything appears to be sorted out with that. the oddity of the 25% power according to them is likely a quirk of the machine, but I should be able to work with it.

So as for the moment my problem is resolved.

Question? Could this possibly be a controller configuration issue? I understand that it requires a certain high voltage level to ionize. And is lower for lower wattage tubes… Is there something in the configuration that has any effect on this? I though I’d seen something on configuring Ruida controllers referencing either voltage control or pwm? Don’t know if I’m dreaming this.

If I were a tech… what steps would be next.? Can you tell the response of the HV? Can’t really tell the voltage with the ma meter since there’s no current flow until ionization. Maybe a repsonce time…

Rsexpress: I’ve learned a ton watching videos from this guy Russ. Here’s a link to one of his videos on lens at RDWorks Learning Lab. It’ll at least get you to where he is on Youtube… He’s got about 200 videos and they all are very informative and addictive. By what you said so far, I think he’ll be right up your alley.

Good luck, keep in touch… we’re on the edge of our seats… (8’)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.