I am going through some heaps of material because I cannot seem to start in a precise location. I understand I could solve this by adding limit switches, but I am sure there must be an easy workaround. I have had to pause a job and move the laser and found it is easier to just try a whole new piece than to try and guess the last location. Willing to Listen!!

Before turning on the laser manually move the head to the front-left of the machine. With the laser head pegged to the front-left, start the machine. That would be considered manual homing.

If you do this very consistently you should be able to get fairly good precision. Sub millimeter certainly and likely sub tenth of a millimeter.

Ok so if I do that often, how do I start my projects exactly where I want them to start, obviously I will be eyballing them unlees you are saying that after I turn the machine on it wll believe it is at 0/0. In that case I understand but then there is the whole lining up on the honeycomb compared to the coordinates question, still not quite understanding how this can be precise.

This is exactly what I’m saying.

You’ll need to elaborate what you mean by honeycomb compared to the coordinates.

And what aspect of what you’re doing needs to be precise.

What I’ve explained is the process to have precise repeatability of laser position. This allows you to have relative assurance that the laser will go the same place time after time for the same given design.

ok, I will try…

- I manually set my machine on the 0/0 positions and cycle on off.

- I select a project and scale it accordingly, I position my material in the center of my work area ( at this point I have no reference of where my material is actually sitting on the “GRID” I have no camera and when the task is done the laser will return where it started from but if I had to stop or abort the job to make an adjustment I am lost and could be a mm or 2 off…next piece of material please.

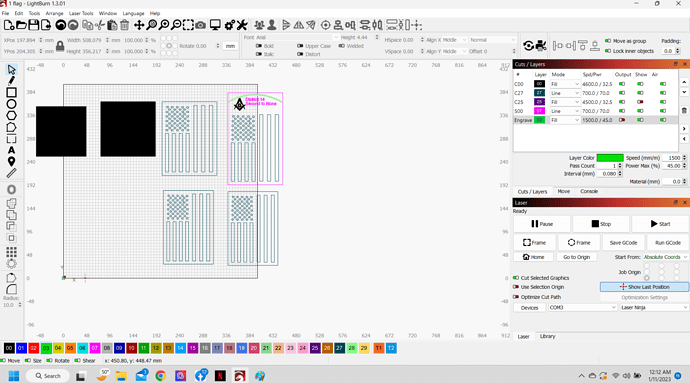

- If I have to break up a project into pieces the reference mark moves and lining things up is even more confusing. Did I explain that right?

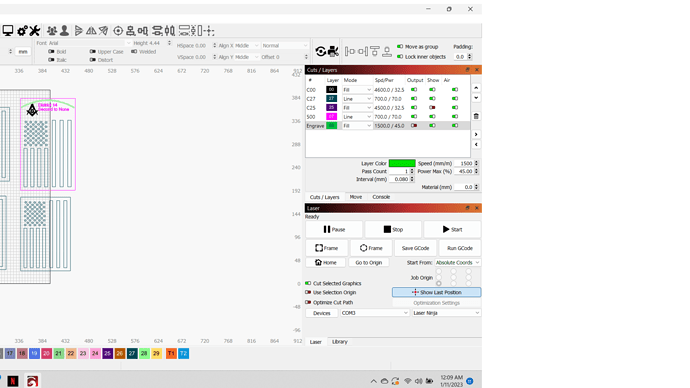

In this image I am trying to make the flag 6’ in height but when I resize it the reference marks move as well and lining things up becomes impossible.

Are you using the framing techniques to position your work material?

If you absolutely must stop in an alarm state then re-home and start again. However, it would be preferable not to cause an alarm state. If you need to stop for whatever reason try pausing first, then stop. But I’m questioning why you’re having to stop so frequently. It should be a rare occurrence.

Can you explain what you’re trying to do here? Print and Cut may be the better way to handle this if you’re trying to burn a design larger than the size of your bed across a piece of material in multiple runs.

What are the reference marks in the image? I don’t see anything obvious.

It does sound like you want to be using Print and Cut for this. Take a look at this video:

Cutting a single project larger your laser (pass-through version) - YouTube