Hello

I’m new to Lightburn and Ruida, although I used for several years Lasercad + AWC608.

My current (recent) configuration :

CO2 Laser tube / around 70W / spot size around 0.2mm / 900mm x 600mm

Lightburn 0.9.18

Controller : Ruida RD6442S-B(EC) purchased by Cloudray Laser recently.

The problem :

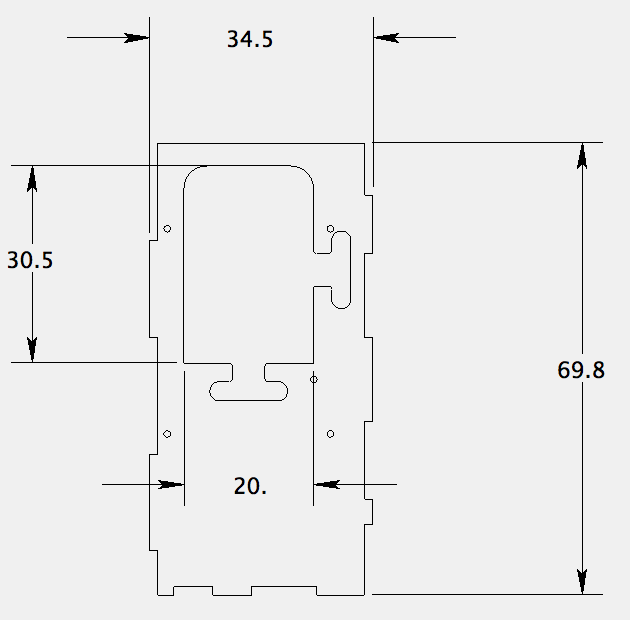

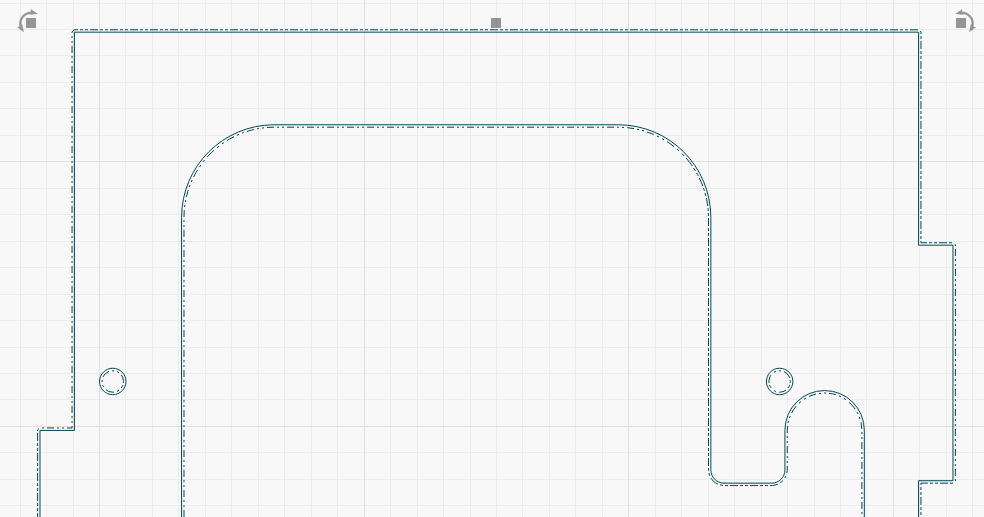

I have 2 shapes, 1 part outline, and 1 opening inside this part, as attached.

When I cut the part,

If I do not use the kerf function : the outline is too short 0.2mm for both X and Y axis with regards to the drawn dimensions, which is to be expected, and the opening is spot on (accuracy around +0.02mm on repetition of the test), which is rather unexpected.

Said otherwise I measure 34.3mm for outline width and 69.6mm for outline height

But the opening is measured at 20mm for the width and 30.5mm for the height.

If I use the kerf function : the outline is spot on the drawn dimensions, and then the opening is too small of 0.2mm on X and Y axis …

Said otherwise I measure 34.5 for the outline width and 69.8 for the height which is correct

But the opening is then measured at 19.8mm for the width and 30.3 for the height

I tried to drop the cutting speed in case some interpolator would maybe cause the problem, from 25mm/s to 10mm/s , same problem.

Did anybody get this problem ? Am I missing a setting parameter ?

The only place I found something is in :

Edit >Settings >File Settings >Output Tolerance >Curve Tolerance (mm)

which I set to 0.005 (mm) ???

Thanks for your help

P.

sample.lbrn (15.8 KB)