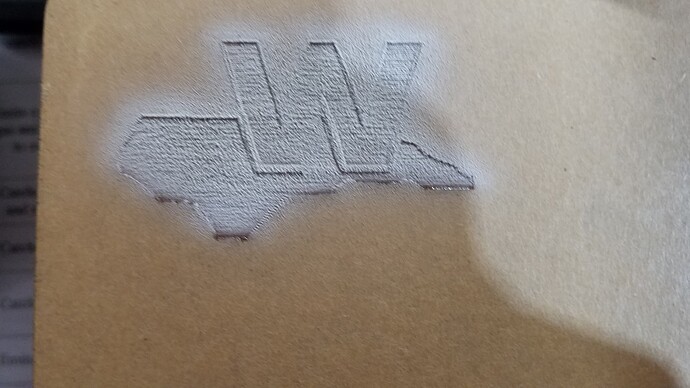

I’m having an issue with the engraving in acrylic fading and loosing the frosted look when it gets to the end of what I’m trying to engrave. I’m using a 150w laser speed of 300mm/s power of 20%.

Does anyone have any ideas on how to remedy this

Are you using cast or extruded acrylic? Extruded engraved terribly. On my 60W I engrave at the same speed and power, but I’m only looking at a light engrave. Not looking for depth for colour filling or anything.

It’s cast. The engraving looks good overall just where ever the end of the cut is, that’s the portion that seems to not get the frost

Have you tried with less power or higher speed?

I’ve tried higher and lower on both actually. It will affect the over all quality of the engraving but still leaves the bare spot either way.

No further ideas Jeff, I do quite a lot of acrylic engraving but never come across this issue.

I tend to engrave with the protective film removed but give a coating of dish soap just before starting the job which stops the acrylic vapour re-condensing around the engraving and leaving a cloudy mark. The only other difference is mine is supplied with film on it rather than paper.

I’ll be interested to see what others comment. It’s all a learning.

Use a level on your acrylic to make sure that the bed is holding it level. Check your focus.

Try engraving in other places on the bed to see if it is one of those problems.

I might be from another planet, but…

Have you tried going from the bottom up? I found weird things occurring when the vent drew the ‘exhaust’ particles over the engraving. I now engrave bottom up.

I agree with the others though, I’ve never seen it at the end…

Barbara : I have double checked the table and it is level and I also get the same result on different positions of the table. Both x and y swing.

Do you have any tips for the focus?

Jack : I gave that a try also. I still get the fade. It really seems that wherever the end position is, that I where the fade is. Start at the top and fade is at the bottom and vice versa. Same for left and right.

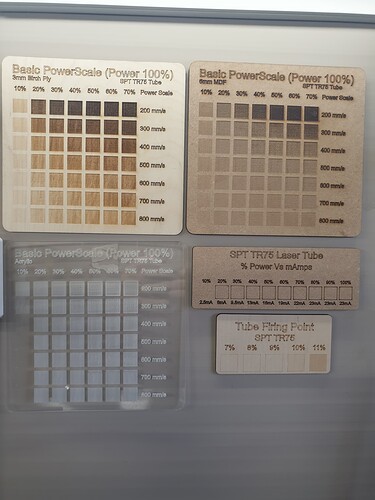

If you still haven’t found a solution two more things to check. Back off a couple off mm on your focal point (slightly further away) but more essentially do a power scale so you may see at what point this issue starts. It will also provide you with a reference for outcomes from power vs speed on different materials. Here’s mine for the main materials I use:

There are several factors causing / possibly causing this. The detail for these can become so granular, I have hesitated to chime in. I will be brief:

- Paper backed acrylic (usually is adhered with an adhesive). Peel that off before you engrave.

- Blasting with air assist. The best engraving of acrylic is using minimal air assist. Even better → none (but then you have to mitigate several other issues by having very good fume extraction, increased safe Z distance (space between the cone and the material), and control for when the job goes from engrave to cut

- Your speed. Too fast a mess is made while acrylic snow showers the landscape. That last “lap” clear result may actually be in every line. The “snow storm” from the next line may be covering it up line after line (while the last line has no tailing storm of acrylic dust). Too slow and instead of frosting you’re polishing

- Lens focal length

- Acrylic type (not just cast vs extruded. there are various formulations of each)

- Line resolution

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.