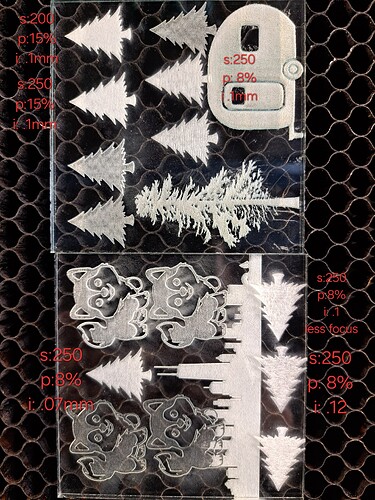

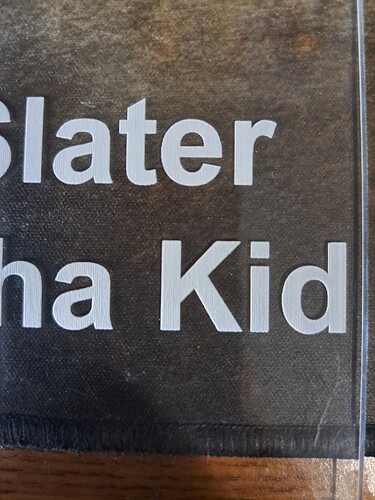

Ive been trying to dial in my settings for engraving acrylic. The goal is to go for a frosted white look but most of all i just want smooth consistent “color” ive tried a lot of settings and wanted to post something because no matter what i change i seem to get decent results untill i brish the dist out of the engraving. Once i do that they all look slightly splotchy. It isnt a consistent solid frost, i hope that comes through i n the picture. The second picture is a product someone bought and its nearly perfect solid white. Long story short im getting the color i want but not the consistency throuout the engrave. The edges are different then the middle and its just spotty with how “solid” white it is.

Are you doing a fill in the trees?

The 2nd image you can see the scan lines, so I’m guessing you should be able to duplicate that. There is also de focusing to get a bigger/softer spot.

You interval is only 0.10mm or there bouts. I know my co2 is a bit over 0.20 spot size, have you tried increasing the interval?

If it’s ok, what don’t you like..?

![]()

i did try to defocus and it turned out worse. when i went to .12mm interval it got worse and when i went smaller it didnt seem to make too much of a difference. im getting good color but if you look closely it is splotchy when i brush the dust away and i just want it to be nice and perfectly even looking.

Are you using very low air pressure?

![]()

Usually 0.1 mm line interval is good. I do see the lines there so maybe you could go a bit lower to get a flat bottom, but it will increase runtime.

If it’s clear acrylic, ALWAYS mirror the image in LB and use the cut side as the “back”. Engraving on the back looks a million times better. Edge lighting looks outstanding.

Spread dishwashing soap (like Dawn hand soap) on the top surface beforehand, no water, just spread a drop around as far as you can and add a bit more if you haven’t reached the edges. This keeps the white frosting of acrylic droplets from welding to the surface. You just rinse off after cutting.

Don’t try to leave the paper on for rastering, it will tint the engraving a dirty yellow/brown

Be sure you have cast acrylic, not “extruded”. Extruded does not look very good when rastered

yes i am, and if you see the 3 trees i didnt label that have the least amount of white to them was where i turned the air off and produced the worst results for some reason

i do all the things you mention. funny you ,mention cast vs extruded though. extruded acrylic can look nearly just as good as cast but just not with the same settings as extruded acrylic has a very slightly different composition usually. the only real difference is you need adjust settings so you are getting extruded hotter to form the same bubbles as cast. its just easier for everyone to get cast acrylic and be done with it though

I haven’t actually tried reducing AA when deep rastering acrylic, but I expect it will give poorer results. The laser turns a significant volume of acrylic into droplets, as evidenced by the frosting prob. AA transports this stuff out of the cut to begin with. I would expect reducing AA, this stufff will condense back into the cut it’s trying to make and blob up

This leads me to a solid suggestion if you don’t like your engraving performance- your setup may need MORE air assist pressure than you can currently give it.

If you’re using one of those common, cheap AA “pumps” that really are just a big solenoid that wobbles back and forth for displacement, those come in many sizes and it’s hard to predict the installed flow rate since the flow restrictions in the machine’s tubing have a strong effect on flow.

Also, those pumps often develop tears and the flap valves harden up as they age, so you can’t count on a pump you’ve been using for a long time to not suddenly become a prob. And hard to identify because AA flow rate is hard to objectively measure.

The flowmeter says the buzzy diaphragm pump is good for maybe 14 l/m through a couple of meters of skinny tubing, which seems OK-ish for what I do. I think bigger tubing would improve the flow, but likely wouldn’t fit in the drag chains.

Then a handful of parts implemented the dual-path hack to put 2 l/m through the nozzle to protect the lens when the layer doesn’t call for assist air:

Works great! ![]()