Is there a way to have LightBurn add a pause in the gcode to allow the laser to cool down on long, complicated cut programs?

Other than manually editing the GCode yourself, there is no means to insert a delay in the middle of the data stream.

If I had your issue, I would break the project into multiple layers. We normally do that for cuts and engraves anyhow. Between those layers, I would insert a layer that makes a couple of slow loops around a big box with the laser power at the lowest possible setting. That should keep the laser cooling fan running to give a cool down period.

Good luck!

A question immediately comes to mind: why is the laser head overheating?

Unless the laser head specs say something different, it should be capable of continuous operation at normal power levels.

Check for dust bunnies living in the fan, crud building up in the heatsink channels, and anything else that will restrict the air flow through the head. Give the head a thorough cleaning, inside and out, and it may well behave better.

Thank you. In retrospect, I think it may have been a silly question. My shop is not climate controlled. I’ve been running my little Creality Falcon 22watt hard. It’s been very hot and humid and I think there hasn’t been enough convective cooling to run it that hard. Dropped the power down to 80% and added and extra pass did the trick. A little longer to take my cuts pays off. Patience isn’t my strength and sometimes I’m reminded of that. Thank you again for your response.

Is there a reason this would not work for you?

Granted, you’d have to run each section as a separate “job output”, but the Gcode below should give you 10 minutes before it will let you run whatever’s next.

Note that normally, G04 Pxxx.xxx is in seconds, while G04 Pxxx (no decimal point) is in milliseconds.

It depends on which G-Code dialect the controller uses!

The original GRBL / LinuxCNC dialect uses G4 P for seconds, with or without a decimal point.

The RepRap / Marlin dialect uses G4 S for seconds and G4 P for milliseconds.

What various manufacturers use in their forked / cloned / pilfered controllers is entirely up to them, as is their level of documentation.

Which converts programming into an experimental science …

well okay, but GRBL is not by any means “original”. GCode–actually RS-274–was created in the early 1960s.

I’m not entirely sure why you left out the beginning of my sentence “Note that normally,”

which was put there specifically to indicate that not all variations of GCode do that.

Programming, and engineering in general is ALWAYS an “experimental” pursuit, not because the outcome is unknown, but because testing’s job is to find defects.

Somewhat surprisingly, GRBL closely follows the LinuxCNC dialect based on the original EMC descending from RS-274: it has an honorable ancestry!

Mostly to make it shorter, while pointing out that the decimal-vs-integer difference (probably) doesn’t apply to the nominally standard dialects used in GRBL-based controllers. While it may be true, it’s not the way to bet for most consumer-grade laser machines.

Note that LightBurn’s Start and End G-Code snippets bracket the entire job, rather than each layer, so they can’t accomplish the original intent of cooling the laser head during the layers of a job.

I believe this is your solution but you have to try:

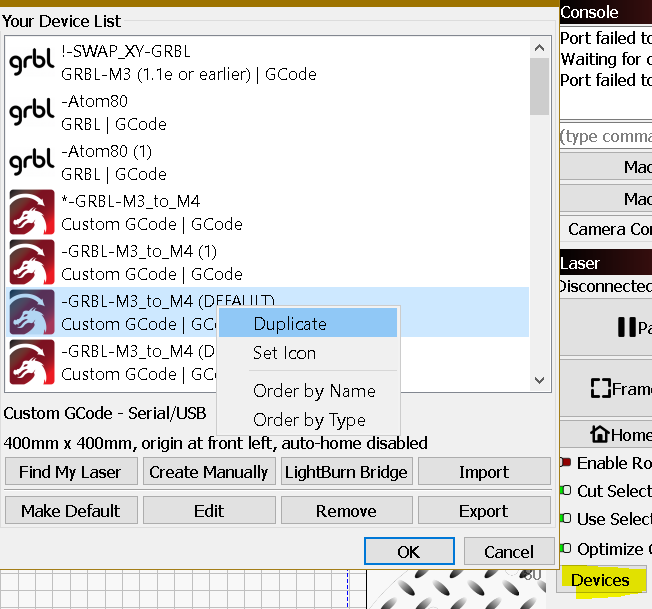

- 1.Duplicate your current laser device by clicking Devices then right-clicking your device and selecting Duplicate.

-

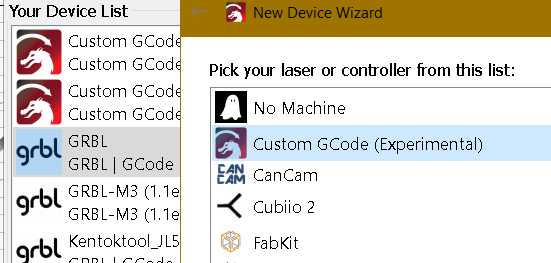

- Edit your Duplicate device and set it as Custom GCode

- 3.In Custom GCode you have a field per Layer Start, input your pause time .

.

Don´t now yet if this works with sub-layers, later will check…but lets say you have a long cut, you can distribute the cut in 2 or 3 sublayers (with less power) and check the output GCode if is per layer and also per sub-layer.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.