Delay on break technically means the implementation of preventing re-energizing the circuit for a set time after break. This is often implemented in HVAC systems to prevent compressor lockout and rapid short cycling. So the term is misleading. It usually does not mean “delay breaking the circuit for X amount of time when the circuit is shut off”. BUT, even the control companies are calling both types DoB controls now. So…

The solution is a common component also found in HVAC systems: Fan Delay Timer. These are relatively inexpensive. Amazon Link

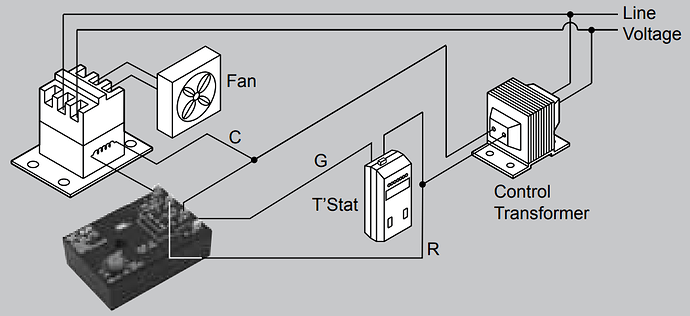

Think “DC coil relay” as the thermostat in this drawing. Your controller would open and close that relay (which would then route 24V AC from a simple 24V AC transformer to the ICM control contacts)

For example, from a Ruida controller, the job status control would output to the DC relay. When the job ran, the relay would close (thermostat ON / fan on). When job was finished (thermostat OFF) the fan delay timer would keep the fume extraction running for the set amount of time.

I should just make a bunch of these up in a clean little package and sell them.