I have the Aeon Mira 7 laser machine. I’m using it to cut 80lb (250 grm) cardstock. I’m having an issue that the paper gets black/dirty from the smoke. Aeon is advising me to get an air compressor to increase the air pressure. I’m new to the whole laser thing and am wondering how this will help?

Considering that your laser is a CO2 machine of respectable design, I’m surprised you’re getting soot on the work. An air compressor able to provide a greater volume of air may push the soot away from the cut line.

You’ll also want to examine the extraction flow as well. Ensure that airflow-in openings are clear and that the exhaust flow is substantial.

I’ve found that running a high speed and a high practical power setting will minimize soot creation, along with the higher pressure air from the nozzle. I’m currently running 30psi / 2 bar for most of the work, although it’s plywood and not paper stock.

Thanks for responding.

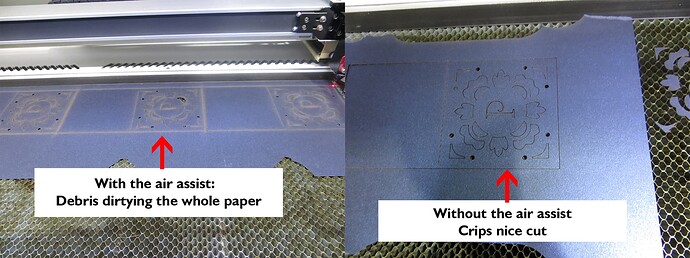

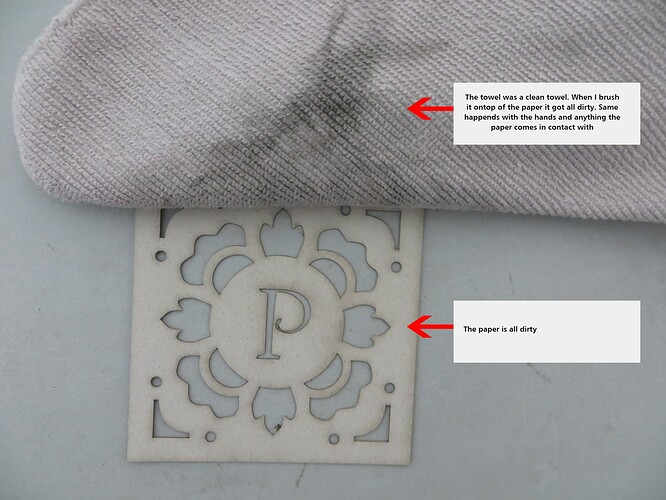

‘I’m surprised you’re getting soot on the work.’ Yes I also felt that something seems wrong. When I turn the exhaust fan on I can see the smoke going to the back of the machine. So the exhaust is working. I only have this issue when I turn the air assist on. It seems like the air assist is blowing all the soot and particulates directly onto my material. When I turn the air assist off the machine stops cutting cuz’ it fogs the lens.

What am I doing wrong???

Too much pressure… turn your pressure down to an absolute minimum to keep the debris off the lens…

When I cut parchment paper, I use water (screw on bottle cap) to see the bubbles off the end of the nozzle… you can adjust it very low doing this… you can also turn it wrong way and blow the water every where… ![]()

Generally higher pressure for cutting, but card stock is an easily cut item with even lower powered machines…

Try lowering pressure… does your machine allow for an air assist output? How do you control air and pressure.?

I run with low pressure if the machine is doing a job, using high pressure when I cut most materials…

![]()

I’ll add my .02.

The laser needs to ‘see’ what it’s working on. for engraving the head is moving fast enough that your exhaust will be keeping the area directly under the laser clear of the out gasses. For cutting, you need air down into the cut to keep the beam path clear of those out gasses.

My best analogy to date, is cutting without air assist is like trying to drive at night in heavy fog with your high beams on. Clear the fog of out gasses and you will get better and more consistent cuts.

How much air will depend on your machine’s physical configuration relative to air flow down through the cut. EXAMPLE: I have an 80W machine with a Cloudray No3 nozzle. I have it set for 13 psi flow pressure for MDF, but I knock it down to 7 psi for acrylic, foam, and other light material. When I do cardstock patterns, I will quite often adjust that down into the 4 - 5 psi range.

It’s the air assist in my machine which is causing everything to get dirty. How can I check if my air assist is working properly?

Yes, I can tell that I must use the air assist - but get soot and particulates on my work piece even when my air assist is only open a drop. It seems like my air assist is blowing dirt - can that be? How do I fix that?

I get that if I don’t have the air turned on. I’m guessing, but I would bet what you are seeing is blow back. Forcing air down through the cut will push it down and out keeping it from coming back on the surface. With cardstock, you can have too much air flow, but as long as it’s not fluttering the cardstock causing focus issues, you should be good. Crank your airflow to max and see what it looks like. Maybe borrow a tank or compressor as a test before you go out and buy one. Can’t hurt.

It’s exactly the same if I do just a drop of air flow or the max amount of air flow. I can lower or increase the air flow pressure by turning a knob on my machine, but I would not know how much psi i’m using. Is there anyway to control the airflow from lighburn?

There is no ability to adjust the flow from LightBurn - only On/Off. There are kits out there that allow you to run a lens purge constantly, then LightBurn can enable high pressure air for cutting - Cloudray Air Assist for a Laser Cutter – Cloudray Laser

Ditto on flow through lightburn.

I’m nat familiar with your machine, so take this with a grain of salt. All too many machines are shipped with a restricted air flow nozzle, what is generally called an engraving nozzle. It’s more the fitting into the nozzle, but tip hole diameter is also a factor Check out the #2 air nozzle pic at the top of my Google Mod Page to see the difference in the fittings between engraving and cutting. They ship with engraving set ups because they can ship it out with a smaller compressor and call it a functioning machine. As a rough estimate, cutting with an engraving set up puts you at a rough 40% disadvantage. It’s what mine originally shipped with.

Thanks for giving from your time. You seem to be a real pro ![]() .

.

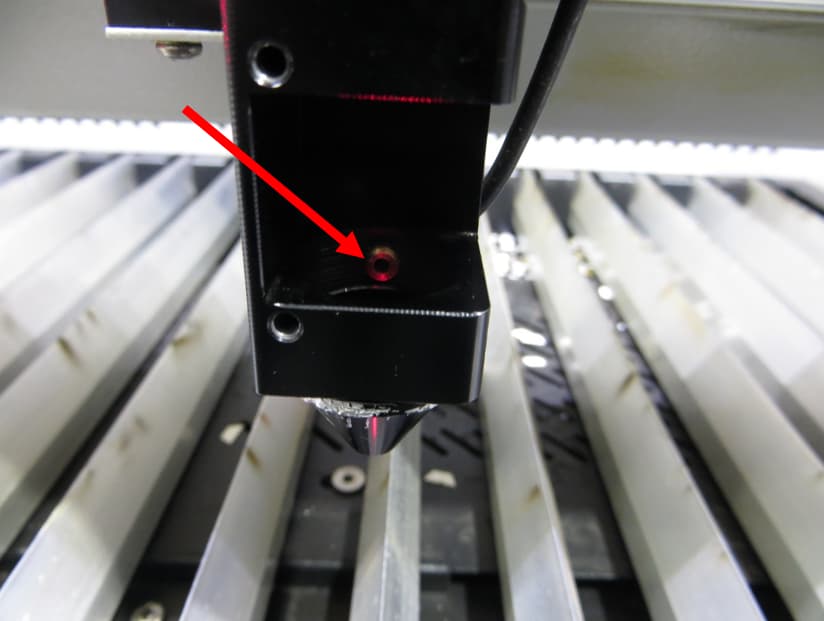

It looks like I have the engraving air nozzle – see image – Also the tip is more like a bit over 3mm. So, you’re saying that changing this can be a real game changer?

Just as an experiment, I tired reducing the power when cutting (although I knew it will not cut through the paper) to see if it makes a difference. But I still got the same amount of soot/dirt. Would that tell me anything?

IMO 3mm is okay. My factory Cloudray nozzle is 2.5mm. Some have drilled out the fitting with mixed results. I fought mine for a while as you can see from all the various lens tube / nozzle pics. Broke down and got Russ’ lightweight head and the Cloudray C Series lens tube and some No3 nozzles. Wish I had done it to begin with, but didn’t have much spare change at the time.

I cut cardboard with the laser and with an air compressor, but the results are not good. The cardboard will always have ash on the edge. Cutting cardboard with a laser works if it is occasional, but I don’t think the laser is dedicated for that. There are other machines for cutting cardboard. Anyway, if you don’t have a compressor at the moment, you must purchase and adapt it to your machine. The electromagnetic membrane compressors that come with the laser machines are toys.

I have a 60W and tried this out the other day with only air assist and it worked well. No soot. So for mine, I believe it was 30 mm/s and 11% pwr. Do you have a picture of your finished cardstock cut?

Dave01 hit the nail on the head with my machine. It came with a compressor that peaked at 4.5psi and a restrictor nozzle.

I ditched the nozzle for an elbow and blew 15psi up it and viola! I could cut ply without turning it into charcoal.

I just tried using my machine without the nozzle and the paper stayed clean!!! What are the downsides of cutting without a nozzle?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.