Previous owner of my 100w co2 red machine has a solenoid switch for the air assist. He has it wired to a small switch next to the controller screen. He mentioned something about having 5he ability to switch on and off manually like that was some feature. I knew nothing about laser cutting at the time i bought it. It ONLY blows air when switch is on. If its off, the settings dont controll it in anyway. Im happy to remove switch, but not sure which wires make the solenoid turn on automatically. He was a stoner, so no telling what he did. No offense stoners ![]()

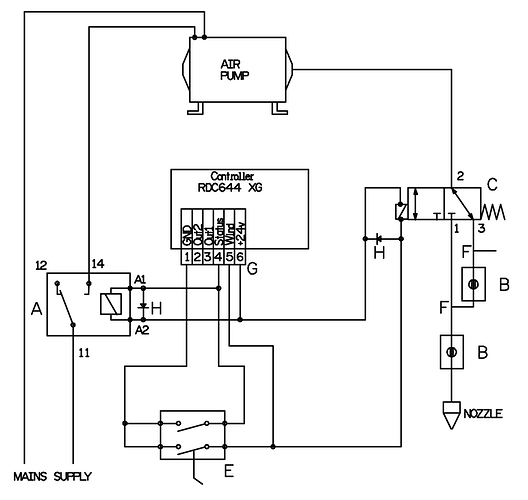

This is the standard ultimate air assist… many vary how they do it, but this is the basics.

Ruida controllers have a pair of outputs, Status and Wind… When they become active, they sink the current, or complete the path to ground. The solenoids connect to 24V, then to the controller…

Status becomes active when the machine is in run mode… Wind is active when it’s running a job and that layer has air assist enabled on the layer…

I and many other use the sinks like this…

A solenoid that allows full air pressure into the system becomes active with Status… This allow full pressure air into the system… It flows into a restrictor, so when you run any job you get low air pressure…

When the layer has air assist enabled, there is another solenoid that bypasses the restrictor and allows full pressure air to the head assembly…

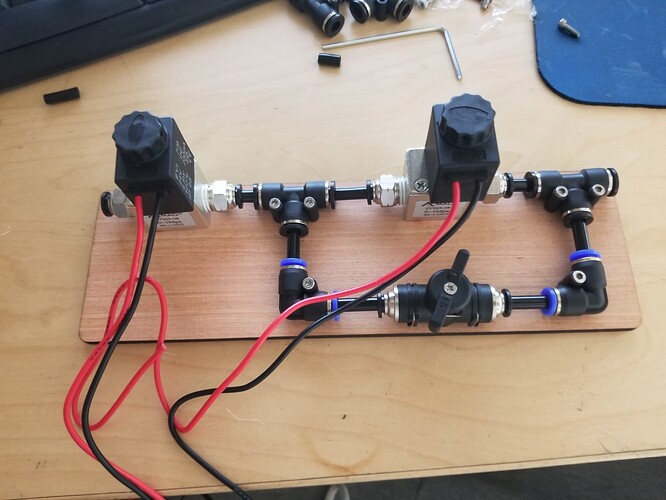

This is my air assist I built on a piece of 5mm mdf… Left is the valve for high pressure. Right side solenoid bypasses the restrictor.

The diagram has the Status enabling the air compressor. But the same thing happens…

Make sense?

You’ll have to figure out how the stoner wired yours up if you want more help… can’t tell from here. ![]()

![]()

The switch may not be wired to the controller, which means the assist air has only manual control.

The controller output drivers have an upper current limit of a few hundred mA that may not be enough to drive the solenoid without a relay. If the switch selected “Auto” and “Manual” control, with the solenoid wired to the controller, well, that may have worked at one time and eventually killed the controller’s output transistor.

@jkwilborn’s diagram gives the big picture, so you can find the controller outputs and see what they’re connected to.

Given your description of the situation, starting with the worst-case assumption and being proven wrong may avoid some heartache and confusion.

I wired both the air exhaust and nozzle cooling air to the door using a small micro switch. My approach is that I don’t want too much inside air vented outside so I wait to open the door after most of the smoke clears. Nozzle air could stay running but I don’t see the need to have it on.

To me this is where a simple solution makes the most sense. Chiller is on all the time and the laser won’t fire if the chiller is off or has an error.