RDC6442G B(EC) I’d like to use my external air supply for air assist in place of the built-in compressor on 130w omtech. On a previous machine I wired a solenoid to the 24v WIND connections and it works fine. The new machine has a few upgrades and already has a wires going to the WIND connection plus a couple of extra relays. I understand from other posts that this likely to be low / high air flow and feed to the extractor. I will only be cutting with this machine so only need air assist ON or OFF and I have external extraction. If I remove the built in compressor and extractor fans, can I simply remove the existing wires from WIND and wire in my solenoid connection ? I’m concerned I’ll provoke errors if I mess with this set up.

If it has high and low are the solenoids already installed? You might just need to hook up your air.

The Wind terminal is an output, so the controller has no idea what’s going on beyond it. You can disconnect the wiring and do what you like.

I’d lay money that plan won’t survive contact with the future.

You could move the assist air tube from the internal compressor to your external compressor, shut off the low-flow path, and the existing hardware would do what you want: high flow only when WIND is active, no flow otherwise. Then, should you have a job with just a little engraving, you could twiddle the low-flow path to restore a smidge of assist air.

Chesterton’s Fence may be in full effect:

The more modern type of reformer goes gaily up to it and says, ‘I don’t see the use of this; let us clear it away.’

Ya never know… ![]()

@ednisley has some good advise, I’m sure he has insight with this also… I agree…

The Ruida signals work this way…

The status becomes active (sinks current) whenever the machine is in run mode. When both status AND the layer with air assist enabled is executing, wind becomes active.

This makes it relatively easy to use status to enable high pressure air into the machine and wind allows for it being active with the layers air assist enabled…

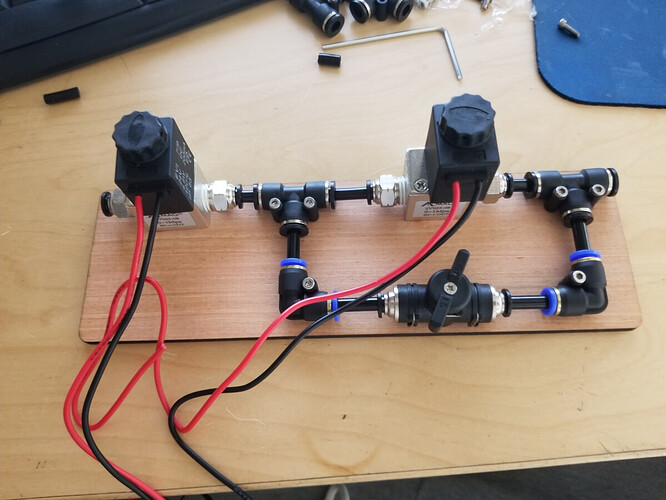

What most do is after the status solenoid, they run it through a restrictor and bypass that with a wind solenoid… This is my prototype… high pressure air comes into the left side…

As Ed pointed out, you might regret removing all the extraneous stuff…

I’d ensure that I knew what all these relays are operating… more then likely they are switching the mains to these devices. They are not switching air they are switching something like the compressor or?

Your resolution of using wind to enable air pressure is sound reasoning… and should work fine…

I quit using relays decades ago, I use ssr for switching mains and these types of solenoids for pneumatics.

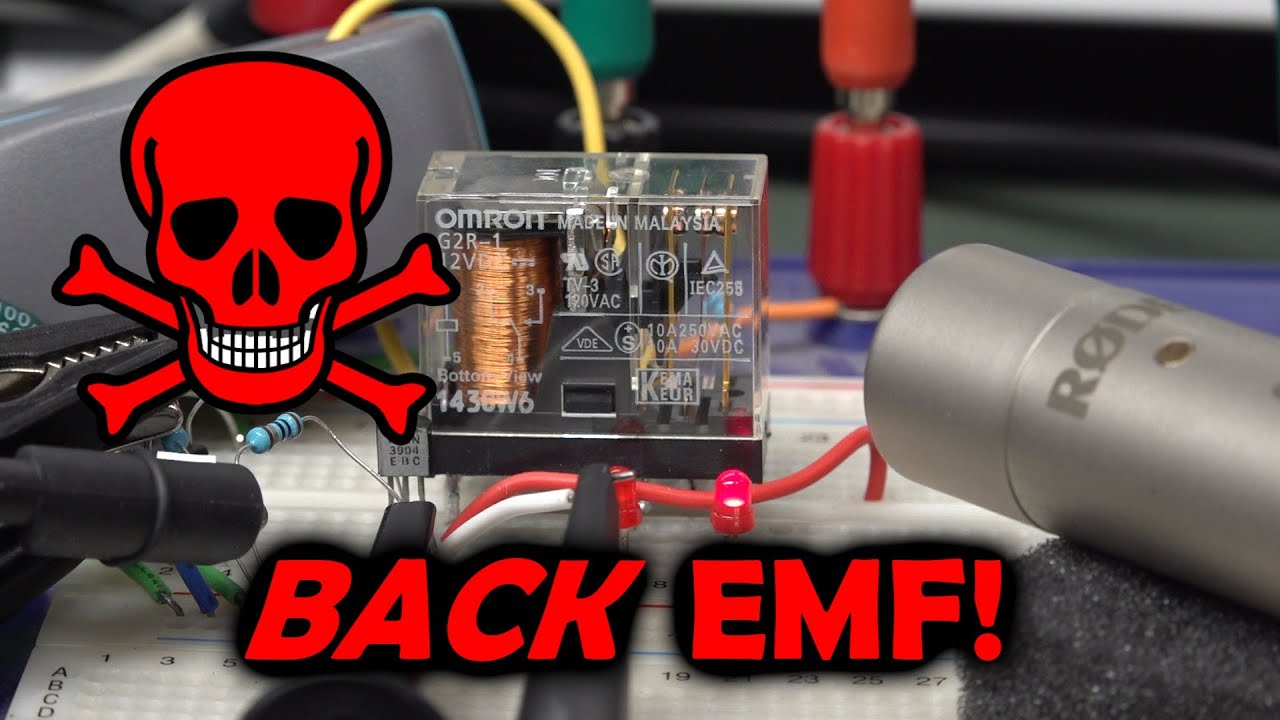

Don’t forget to add snubber diodes to anything with a coil you are driving with the Ruida, or anything else…

Good luck

![]()

Thanks all for the advice. I can’t risk disabling the machine so I won’t attempt anything beyond my tech capability.

I can’t be sure what the additional relays operate. The two wires from Wind each go in the direction of 2 different relays. The built-in compressor is hard-wired to the power supply that also feeds the extractor fans so I am assuming that the likely options are 1 Extractor On with Low air, 2 Extr On with high air and 3 Extr and air off.

So, if I remove the existing wires from Wind, remove the built-in compressor and extractors, I should be OK to wire in my 24v solenoid. I’ll lose low air but this set up shouldn’t affect anything else?

With caveats:

- The solenoid coil must not require more current than the Ruida output can supply

- You must ensure the coil has a catch diode to suppress the voltage spike when the controller output turns off

The 6442 manual (for example) specifies 500 mA and other controllers are in the 300 mA range, so verify your solenoid draws less than whatever the manual for your controller says.

Similarly, many DC solenoid valves have an internal diode, but make sure yours does or install an external diode.

Thanks Ed,

Power looks to be OK but none of the data sheets for my solenoid mention a diode. Fitting an external diode - my tech abilities are a few levels below you guys so maybe safer if I source another solenoid with internal diode.

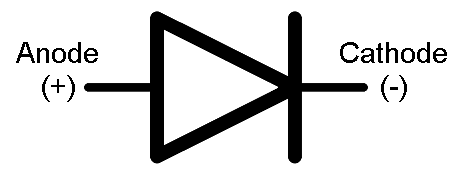

A quick guide to diodes…

Electron flow is from the cathode (banded end of device) to the anode. If you ground the cathode and put B+ on the anode it will turn on and conduct… with enough current your diode will fail…

With a snubber, you install the diode with the arrow (cathode) pointed towards 24V…

When the field collapses, just like in a transformer, it will induce a pulse of very low current of the reverse polarity, and the diode will turn on… this shorts out the spike…

I use a very common small signal diode, the 1N914… you can get them at Amazon… more than you’ll ever need or want…

You can put them at the Ruida if you wish… from 24V (cathode) to the sink (anode) signal…

Their is virtually no current involved, but if you don’t drain it, the minor amount of current becomes voltage… it can reach a few hundred volts if not dealt with.

Here is a link to eevblog on these issues… it might help to watch it… The more of these you see the more you will pick up…

Make sense?

Good luck

![]()

Diodes ordered. I’ll post once more in a few days with details of the install.

Thanks to all.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.