Is there a time when I shouldn’t use air assist.

I don’t think it’s a should or shouldn’t use air assist.

I’ve done a few engravings in wood at a lower power and don’t use air assist they turn out fine.

If your wanting to cut with the laser, then yes I believe air assist would be good.

IMHO: It all depends on what your wanting to do.

![]()

Air assist makes a huge difference when cutting through materials. If I’m engraving something I generally don’t use air assist or I will set it low.

As far as I know, “Air assist” is the name given to the system that makes an air flow cool the laser diodes (well, laser source), and, probably incidentally, blows on the part at the point of impact of the light beam. When discovering LightBurn, I suppose that some controller of these CNC/laser machines has an electrical output allowing the start of this system (-: a simple air pump like those in aquariums, finally). If I am not mistaken and it is so, the non-operation of the pump brings acoustic tranquility to the user (and a lighter electricity bill), while the reverse allows a temperature closer to the ambient temperature to the laser system and, possibly, the dusting of residual matter particles resulting from the impact of the light on the part.

In my case, the system does not have an “Air assist” electrical output, but controls the temperature of the diode(s). So if the temperature is too high, the system goes into alert mode, which, again in my case, undermines the work already done. So I leave the pump running continuously.

As a general rule I always use air assist.

When cutting helps a lot as already described.

When engraving with much less intensity but always air flowing, not so much to improve engraving quality but mainly to keep fumes from the lens and laser module away.

Air Assist does not cool the diodes. That is the job of the fan on the top of the laser module.

Air Assist blows air through the nozzle, which keeps smoke and most debris away from the laser lenses. For this reason, I always keep air assist on with my S30 and iCube machines. After a year of use, my lens is crystal clear. The SF-A9 machine always has the compressor on when the laser is running. If Air Assist is enabled in Lightburn, then it will go to full speed for maximum air flow.

The Primary purpose is to aid when cutting through materials.

Thanks for your answers,

Anyway, on the OLM3, the air from the pump comes on top of the laser module, and of course, there is a cooling fan on one side. Also, it seems to me that at the beginning, when I was using a lot of laser power without “air assist”, the system was going into alarm. Also, I assume (and hope!) that the particles do not reach the laser diode(s) through the fan, without the “air assist”.

Before LaserBurn was used in testing, the “air assist” pump was powered at the same time as the workshop ventilation AND the OLM3…

New product? ![]()

Yeah, that product created in your mind by using other Grbl well known software before start using Lightburn. I’ve been there too. ![]()

![]()

How do you lower the intensity of air flow?

With something like this.

https://aliexpress.com/item/1005006916132159.html?

It restricts a lot the flow but works for me.

How to set it up on the manufacturer’s air assist?

Many CO2 air assists are connected to the laserhead using a Festo-type hose clamp.

There is a version of this hose connector that includes a thumbscrew to adjust the flow:

I inserted the flow limiter, with a threaded adapter on one side that fits the hose on the other between air pump and laser module. In my case, the adapter it was made in 3D just so I wouldn’t have to buy one.

In other words, a hose comes out of the air pump, passes through the flow limiter, and goes out to the nozzle of the laser module.

Excuse my poor English, but I’m having some difficulty finding the correct words in the translation.

I hope I made myself understood…

Micky Mouse, search for Jack Wilborn’s (@jkwilborn ) solution to the high & low flow Air Assist. Nice design and I think it is fully controlled by the laser machine, and thus Lightburn.

I have a manual 2-flow-rate setup. I added a “T” fitting and a PVC ball valve off the “T”. With the valve closed, high flow, valve open dumps air for a low flow. Works like a charm, but memory to switch not so reliable.

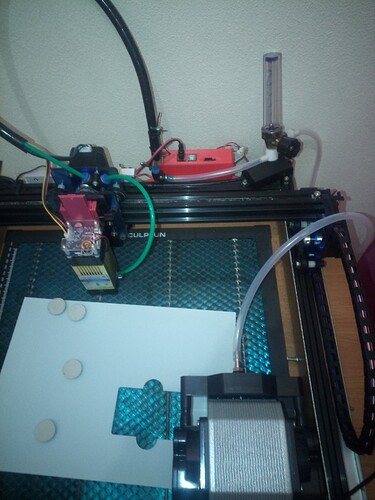

Sorry, but I did not understand you, can you just take some picture of it so I can see.

You are right, Mike. I am still testing LightBurn, so the “Air Assit” pump is always powered outside of the OLM3, and yesterday I ran the laser at full power without “Air Assit” for several minutes, and the OLM3 did not go into alarm )-:. On the top left of the laser head, the “Air Assit” tube connection…

(edit) Now I can power up the OLM3 normally, thanks to the discovery of the right click on the “devices” button: towards the bottom and right of the main window, “laser” bookmark, “Devices” button.

Of course miki!

Sorry for my late reply and for my bad english translation. (google translator don’t work very well with portuguese language)

Now I am working. At the end of the day, when I get home, I take a picture of my machine air assist for you.