Does anyone ever use inert gasses like Argon for air assist? I’m running my first test with thin paper and lace patterns and I’m getting a lot of areas that burn even on low power. Is there ever an advantage to using something else in the nozzle? Argon, Helium, and CO2 are what I have easy access to right now.

Here is a good write up on paper cutting with a laser

The issue with a ‘regular’ laser engraver is that most of your gases are going to be evacuated by your extraction and replaced with air.

Ok, good point. Like trying to MIG weld on a windy day.

One trick is to use engrave instead of vector cuts.

When contemplating strategies like this, don’t forget to include the cost of the gases that you plan to use. Most gas cylinders only contain around 300 cf of gas and that gets used up pretty quickly in the typical air assist flow rate. The aquarium air pump on my Nova 24 delivers around 20-40 cfh of air so a cylinder might only last 10-20 hours of use. You also want to beware of the possibility of asphyxiation if you work in a small area with no or little room ventilation. Probably not an issue, but the results if it is a problem can be catastrophic.

Ventilation is not an issue! The big fume extraction blower on the roof is massively oversized for what I’m doing. And for the occasional run I feel like argon wouldn’t be super expensive, but it sounds like the ventilation airflow would disrupt the blanketing gas too much to be useful.

Long passed your last reply, but we have experimented with argon a bit here at work trying to get a better cut on some plastics. We did see improvements, but not enough to justify the cost of running argon on every machine (8 lasers). We found have a better, consistent air output helped our cuts immensely. Enough that we are looking at getting a screw compressor to provide air to everything instead of just the little aquarium pumps. Hopefully that helps a bit.

Good timing to bring back this post, I just switched yesterday from the aquarium pump to my workshop air compressor and the difference cutting 1/2" MDF is amazing, cleaner and deeper cut, but mainly virtually no browning around the cut (lower words with the old pump, upper word with the air compressor)

Hi @Chrik

What kind of aquarium pump did you have?

Which performance, brand & model?

@Tomka , you mean the old pump provided with the laser initially that I’m not using anymore?

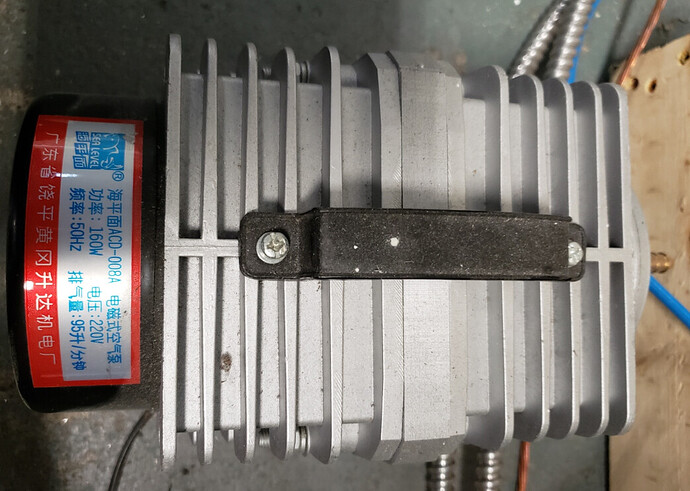

It’s a SEA LEVEL ACD-008A of 160W

Thank you. That’s something bigger than the small pond pumps.