Check this Snapmaker wiki:

https://wiki.snapmaker.com/en/Snapmaker_Luban/manual/laser_job_setup

If you mean that the Origin is Top-Right according to your Snapmaker and the Origin is Bottom-Left according to LightBurn then the Snapmaker is a Negative Coordinate Machine.

In LightBurn, with the origin selected Bottom Left, apply a workspace offset to the coordinate system in the Snapmaker by entering the following into the Console window in LightBurn:

G10 L2 P1 X-600 Y-400

Followed by Enter.

This should correct the errors you observed when jogging the machine. Please test and report back. More information available here:

Automatic translation to German (below):

Hello

Thanks for your help. I think the wrong position is the problem but G10 L2 P1 X-600 Y-400 is still not the right solution.

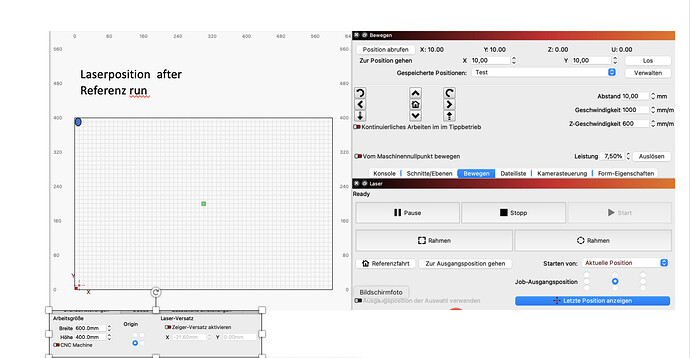

I start X10 Y10 after the reference run

the laser moves X correctly but Y in the wrong direction.

If I drive the laser while jogging, the laser Y drives correctly.

Then you need to use G10 L2 P1 X-610 Y-410 to get to 0,0 afterward.

I understand that jogging works correctly? Then the firmware parameters are correct. If the job inverts the y-axis, the origin is set incorrect.

Ich habe jetzt folgendes gemacht

- Home run (hinten links)

- G0 X0 Y0

- Ursprung hinten links

Laser position ist identisch in lightburn.

X achse fährt korrekt

Y achse fährt in die falsche richtung

Y Jogging fährt auch in die falsche richtung

I have now done the following

Home run (back left)

G0 X0 Y0

Origin at the back left

Laser position is identical in lightburn.X axis moves correctly

Y axis moves in the wrong direction

Y Jogging also goes in the wrong direction

Dann musst du in der Firmware die Richtung der y-Achse umkehren.

Then you have to reverse the direction of the y-axis in the firmware.

This generally indicates that the Origin (Back-Left) is not as the manufacturer intended it to be. Because the X-Axis behaves correctly, the origin is on the Left. To make the Y-Axis behave correctly, we generally move the origin to the other end of the Y-Axis (From Back to Front). Because this engraver originated from a CNC machine, I believe that it is originally intended to operate in a Negative Coordinate space from an origin Top-Right.

The workspace offset method moves the origin from Top-Right to Bottom-Left to allow the engraver to respond as intended to Positive Coordinates from LightBurn.

If the Origin must be in the Back-Left corner, one can modify and reverse the axis settings.

Modified axis settings won’t survive the basic troubleshooting steps where GRBL settings are reset with $RST=* or $RST=$.

I’m concerned that this generates more confusion and work than it’s worth.

To confirm that the axis settings are as the manufacturer intended them to be, Please enter the following in the Console window in LightBurn pressing Enter after each line:

$$

$RST=$

$$

Please select and copy the results of the reports and the command (in order - all at once) and paste these results into a reply here.

We didn’t start troubleshooting here by resetting any possible stray settings such as axis reversions. There may have been something unintentionally reversed.

$$

$0=1

$1=100

$2=0

$3=2

$4=0

$5=0

$6=0

$10=1

$11=0.006

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=1

$24=300.000

$25=3000.000

$26=250.000

$27=2.000

$30=1000.000

$31=0.000

$32=1

$100=80.000

$101=80.000

$102=100.000

$103=35.556

$104=100.000

$105=100.000

$110=30000.000

$111=12000.000

$112=1000.000

$113=3000.000

$114=1000.000

$115=1000.000

$120=2000.000

$121=200.000

$122=200.000

$123=500.000

$124=200.000

$125=200.000

$130=600.000

$131=400.000

$132=300.000

$133=3600.000

$134=300.000

$135=300.000

ok

$RST=$

[I][PLAT]Settings reset done

[I][PLAT]Position offsets reset done

ok

$$

$0=1

$1=100

$2=0

$3=2

$4=0

$5=0

$6=0

$10=1

$11=0.006

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=1

$24=300.000

$25=3000.000

$26=250.000

$27=2.000

$30=1000.000

$31=0.000

$32=1

$100=80.000

$101=80.000

$102=100.000

$103=35.556

$104=100.000

$105=100.000

$110=30000.000

$111=12000.000

$112=1000.000

$113=3000.000

$114=1000.000

$115=1000.000

$120=2000.000

$121=200.000

$122=200.000

$123=500.000

$124=200.000

$125=200.000

$130=600.000

$131=400.000

$132=300.000

$133=3600.000

$134=300.000

$135=300.000

ok

Hallelujah

was able to do the 1st job. Thanks for the support. Now there is another problem with the suction, it runs the wrong way around in lightburn. Is there a solution?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.