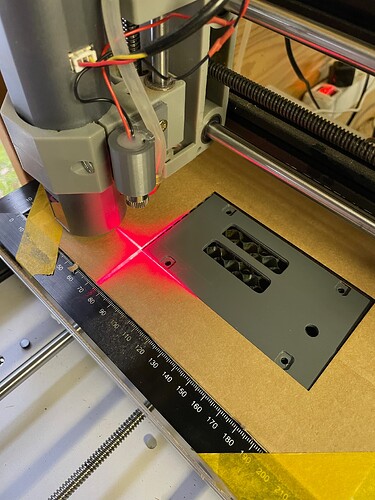

Hi, I am making small panels for flight simulation. In the picture you see the faceplate of one of the panels. The material is white acrylic, I cut them with my CNC, spray-paint them and I want to add text and symbols. I have cutout a rectangle in cardboard in the size of the faceplate as a template. How do I align the laser when I want to engrave the text and symbols on the right spot? In LB I have the same faceplate including the text and symbols. I thought that when I just put the start at the lower left corner, it would work but it doesn’t. The frame option shows me a different work area outside of the template. I’m confused now. Any idea what I’m doing wrong?

In LB (start from = current position, job origin = lower left corner)

I described my preferred way of aligning such projects here: Coordinate systems & workpiece alignment - Diode Laser Wiki

The reason machines perform a home operation, they then know where they are…

It appears your engraver does not have home switches?

It would simplify your life to install them and use absolute coordinate mode. Where it is on your workspace is where the operation will occur.

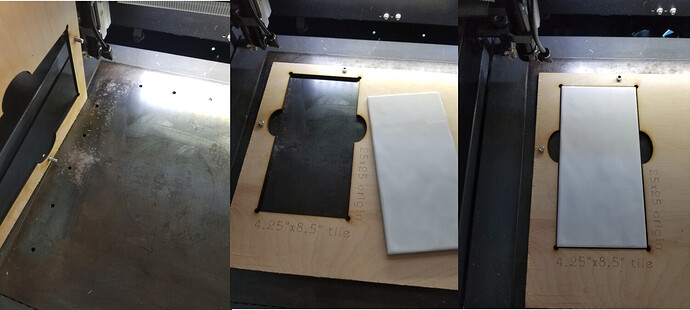

I run many jig project and did so on my cnc3018. Here is how it’s setup on my co2…

Home switches are a cheap investment and makes your machine much more accurate.

Good luck

![]()

I think that’s a good idea. I did install home switches on my other 3018 cnc, I can do the same on my 3018 laser… I think 2 is enough, right? (For the lower left corner X and Y)

Thanks Melvin, I will check it out!

Correct, wired Normally Open.

Probably need 3, one on the Z axes… Most of these home all axes or none …

Does the one you have homing, have a Z axes?

![]()

Yes, both 3018 Pro’s have a Z axes. On the CNC 3018 I just installed 6 limit switches. I can do the same on the 3018 with the laser. The only thing is that I might be buying a “real” diode laser that’s a lot faster and a bigger working area. I have seen the Ikier K1 pro (20W output) and that looks like a good 20W machine… I was going to wait until the end of the year but I might get one sooner.

Other than that, 3 limit switches is also not that much work…

I relate to the as home switches. Most grbl use home switches that double as limit switches.

The Ruida controllers, home to these switches, then they are ignored. It start watching the limit switches after a boot.

Three will get you going, six won’t hurt anything…

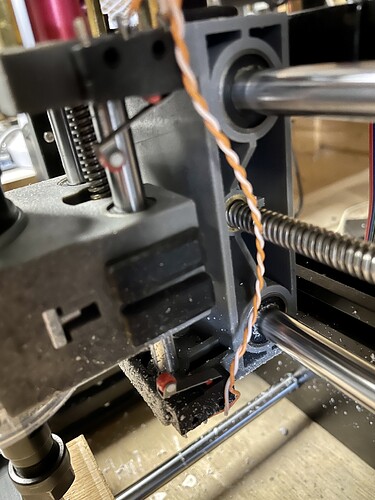

This is my Z home and limit on the cnc3018… It’s center mounted with a magnet on each end of the orange piece. It is a digital hall effect sensor.

This is a 6 second z home… you can see how it works with a single sensor. This one has 5 limit switches.

![]()

Aren’t limit switches the same as home switches? This is what I did with my little 3018 CNC, I had some switches laying around and I printed some simple brackets for them. I can do the same with my laser 3018. I didn’t know that there were fancy magnetic ones! ![]() Nice!

Nice!

It just depends on the controller. Grbl seems to use them for both. DSP controllers have separate home and limit input.

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.