There are a couple of ways… the real question is what kind of precision do you need?

The first is the tried and true was of cutting out a jig to hold the item in the position required. This is the same as using some kind of alignment pins…

I followed this on one of my projects… On the cnc with the scrapboard I drilled two locating holes at the 10mmx10mm and and at the 120mmx120mm. Inserted pins…

Did the same with the table on the laser. I mark where the holes need to be in the material on the laser, drill them and use the same absolute coordinates for both machines…

Similar idea…

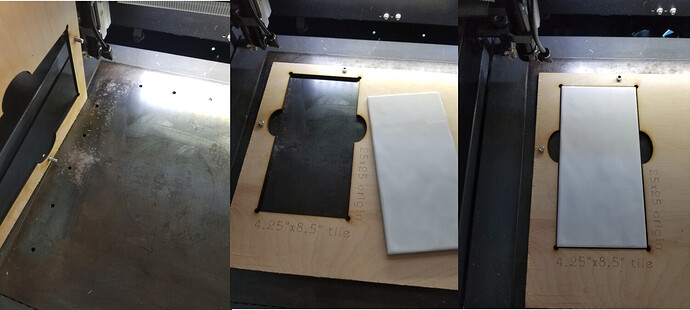

You can also make a cutout to hold the piece that somehow keys to your laser/mill. That’s how these are made for porcelain tile… I use the holes in the table for alignment pins… the precision here is within a couple of mm, fine for duplicating tiles…

If you have a camera on the laser, you can use cut & print. Mill it first then use cut & print to align the laser…

Good luck

![]()