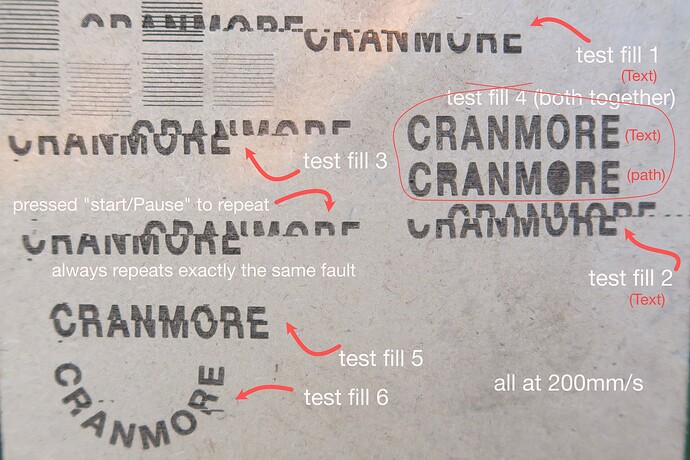

I have been very happily using the fantastic Lightburn for about five years with no issues, this week mid-job the power instantly dropped by about 50% and images being filled, especially text started to jump about on the x axis, I can burn, say, some text or filled image and it will jump at some point in a different place randomly at each send, importantly, if I press start/pause on the Ruida controller to repeat the job it repeats the fault exactly. If I turn text to path it will still glitch, but if text is put with paths as in ‘test 4’ often it is fine…

Anyone seen anything like this? Over the last few days I have started and restarted the computer and laser about fifty thousand times!

Dump the usb connection and

![]()

That evidence says @jkwilborn has it: something has gone wrong with data transmission to the laser. Because it’s damaged in transit, running the same stored-after-being-broken file will produce identical results.

If you’re using USB, do exactly as he says. You can try using a better cable, because its connectors may have been damaged after being plugged & unplugged a zillion times.

If you’re already using the Ethernet port, then it’s likely the router on your network has handed another device the same IP address as the laser. Fixing that can be either straightforward or impossible, depending on how your system is set up.

Let us know how the laser is connected so we can proceed …

Thanks for the reply Ednisley. Yes, USB Cable, had my suspicions and had ordered a new cable, so I will pop on a new one and try it out

Just tried a spare cable 4 metre usb type A to type B… with the same result

Very long cables tend to not work well, perhaps because typical USB cables from the usual sources aren’t the best quality.

Unless you’re using an active extender cable with power injected at the laser end, that’s the problem right there.

Some previous discussions cover what’s happening and maybe some solutions:

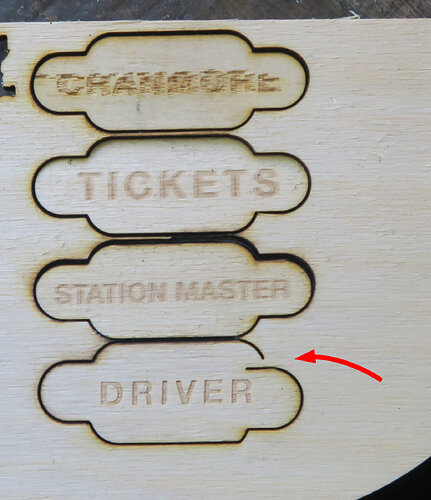

Not sure if this is another clue, but after several cuts, the final few centimeters cuts a reduced scale or curls in on itself, this happens most times…

An intermittent communications problem will eventually show up, so a relatively short job will have relatively more problems near its end.

Another report:

Seriously, use Ethernet …

Right… Ethernet it is! time to hunt through several boxes for a cable long enough, Thankyou. Will report back.

Keep the router’s DHCP range in mind when you set the laser IP address.

A quick test will be to ping the laser’s IP address before you plug in the cable, because if anything responds, that address is already in use:

Assuming the coast is clear, then you can set up the laser and see what happens.

However, the router may give another device that IP address in the future. You should configure the router to avoid doing that or keep it in mind when random errors reoccur.

Aah thanks for the advice, I have found an ethernet cable and unsuccessfully connected anything to anything, but after a few hours, well, a lot of hours, the fifteenth tutorial I watched for more clues eventually mentioned I needed a ‘crossover’ ethernet cable… hopefully that will arrive soon. Is Ping something a Mac can do?

It behaves the same way as on Linux / Unix / Windows machines:

https://appleinsider.com/inside/macos/tips/how-to-test-your-network-or-server-using-ping-in-terminal

In theory all recent (as in, “this millennium”) hardware auto-switches as needed, but I have no idea what goes on inside Ruida controllers.

Let us know how the story works out … ![]()

Only if your hardware was created in the last century. @ednisley is correct, there should be no reason to use a crossover cable.

You cannot plug an Ethernet connection directly to a PC unless you know enough about networking to configure your pc port.

I’ve run mine off one of my ports, it’s really a pain if you don’t know how they talk and what’s missing on your pc.

Plug it into your router/switch of your lan. You will have to deal with the Ruida having a static IP, but that’s not really an issue.

Where are you plugging each end of Ethernet line in?

![]()

The ethernet crossover cable eventually arrived and plugged in, and as you thought, no difference…

(One end directly into the unit inside the laser machine, the other end into the Mac).

I followed several tutorials by several people as to how to set the ip address, all different instructions, still making no difference, then one tutorial mentioned the default ip address on the ruida controller was 192.168.1.100 , so I put that into the ruida controller and it worked… after picking myself off the floor, I checked the ‘devices’ setting in Lightburn and the number was different, (I was under the impression the these two ip addresses had to match), anyway, it worked perfectly… the next day I happily started to work and turning the machine on expecting all to be back to normal and there was no connection again, I looked at the ruida and it was all in Chinese, odd. So I eventually turned it back to English, also found the ‘devices’ in Lightburn had defaulted to an earlier setup so changing that back all worked again perfectly, no random shaped cuts, all fills now accurate and sharp edged, so all working well thanks to you guys helping me out. Or so I thought… the only problem left is the laser power is now about forty percent, not sure if the laser has suddenly gotten old and is failing or there is an overall setting somewhere that has changed, the laser itself is putting a purple beam down the tube and looks healthy enough, (not that I would know), but a failing laser looks pale… or so I am told. I would like to perform some sort of test on the tube before ordering another. Sorry, that was rather long winded, but thanks so much for your help!

ethernet cable

Up at the top, you mention you’ve been using the machine for about five years.

Unfortunately, that means it’s about time for some hardware failures:

- Laser tube life is utterly unpredictable

- High-voltage power supply to the laser tube

- Low-voltage power supply (controller, motors, etc)

A glitchy low-voltage supply (typically 24 VDC) can cause mysterious controller problems. The sellers sometimes / often / always install a power supply with a lower current rating than the total drawn by all the hardware. This works, because most supplies can produce more current than their rating, but it tends to cause early failures.

Those supplies are relatively cheap and easily replaced, so when the controller gets glitchy, replacing the supply is the first step.

This can be caused by an old tube or a failing high voltage supply. Given the age of the machine, it could be either or both.

Before jumping to conclusions, verify that the tube is resonating in the proper mode. This lengthy discussion goes over the details:

If the tube isn’t resonating in TEM00 mode, then it’s time for a new tube. If it does seem OK, then I’d suspect the power supply.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.