I am new to laser engraving and would like to monogram silicone watch bands for apple watches. I have been playing with the settings some but am still getting these little lines. Any suggestions on settings changes?

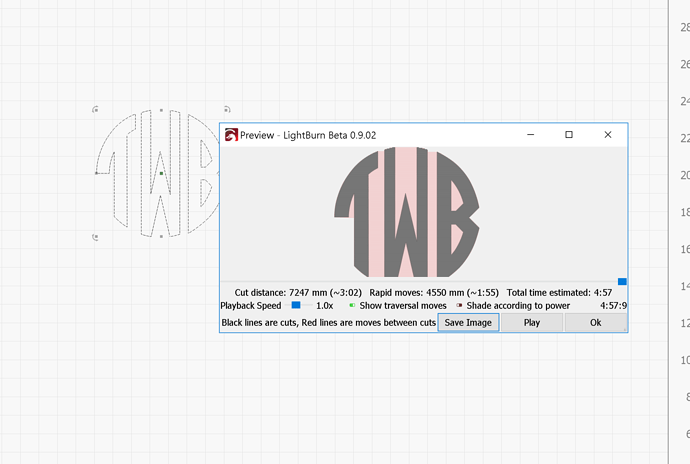

Not sure I understand what you are “seeing”. Share a screen capture (not cell phone picture) of the ‘Preview’ window (ALT-P) and a picture of the resulting cut to help us “see” what you do. We can go from there.

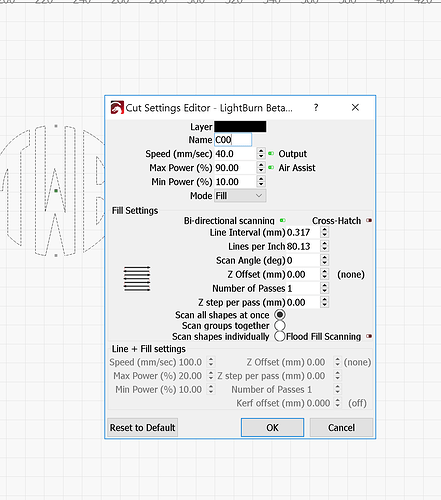

That line interval is pretty coarse at 0.317mm.

Try tightening that up to 0.1mm and see how it goes.

I have not personally tried cutting silicone, but agree with Hank. Setting the ‘Line Interval’ closer (smaller number) reduces the “gap” between each scan line. Your beam has a measurable width, so you might want the scans lines to overlap each other slightly to remove these gaps which under your current setting are being left behind.

You’re also using a Max Power setting of 90%. If you reduce the interval down to 0.1mm, you should drop the power down to about 30% (as a starting point) - reducing the gap between lines means you’re putting more “power per mm” into the material, so you should lower the power to compensate for that too.

Thankyou. Where would you start out with the speed in this instance?

I’d use the same speed you were using already.

You could go higher with speed as well, in fact, if you tripled it to 120mm/sec and reduced the interval to 0.1mm you could leave the power setting as is.

It is a little better at 120 speed/ 90 power and 0.1mm. I am creating the monogram inside Lightburn with ttf fonts. I’m not importing a graphic. Does that make any difference?

Thanks for everyone’s help!

I have tried to engrave silicone before and it is just a terrible material for laser engraving. I was never able to get anything close to the quality I would need to do it for a customer.

You could try using lower power for less depth, and possibly lower the interval even more. It’s quite possible though that what Alan says is true - some things just don’t laser well.

You can also try going out of focus… The laserbeam is basically hourglass shaped, so if you increase the distance to the laser head, the beam focal point will be above the material, causing 2 effects that in certain circumstances (like the current) can be desirable:

- Less power per mm²

- Wider beam (more overlap if so desired)

However keep in mind that too much overlap will generate pretty much the same result as not sufficient overlap, because whether you engrave part of it more, or skip engraving part of it, the result will be similar lines.

Another option you could try is crosshatched fill, but you would need to further lower the output still…

And when doing tests, use simple shapes (squares) and put them side by side with different settings, so you can compare the results of the different settings at a glance…

I have never tried engraving silicone yet, so YMMV!

Could you tell me what laser you use? is that I am new to this, and to begin with I bought an ortur and I want to do the same as you, customize apple watch bands, but I can’t find how to adjust it so that it looks good, I have verified in different sites but I have no success with the engraving. thanks