I used the circle tool in LightBurn to draw a 30mm diameter circle and I cut it out of 4mm hardwood. I noted that the surface of the curved edge looks like 1.5mm lines making up a curve vs a clean arc. Is there an option I need to check out so my laser cutter moves in an arc vs a series of short lines to make up the curve?

I see this is for import/export. Does this also influence what it sends to the printer?

Lightburn breaks up any arc/curves into individual straight line segments when output to laser.

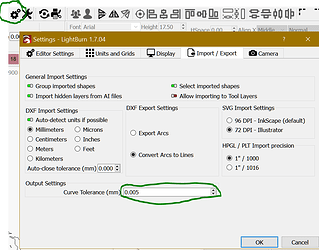

From documentation - Curve Tolerance specifies the maximum amount of error allowed when projects are output to your laser. The lower the value, the more accurate the curve will be. A value of 0 would be “perfect”, but would create very dense data, as some lasers can only process line segments. Most users will be fine leaving this at the default value of 0.05 mm.

Thanks for this information. I’m curious if this is a belt ripple artifact. I need to play with belt tensions first. I minimized Y axis belt ripple in my Prusa MK4s prints by replacing the smooth idler with atoothed idler.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.