I purchased a 20 watt laser atomstack with the lightburn software.

They provided me with a file with the cutting settings for the material. in my case I would like to cut a 0.05mm steel sheet. The document indicates a power of 80% with speed 500mm/min.

The problem is that I can’t cut it even at full power with repeated passes and variable speeds. I also checked the value at $36 but it is already set to 1000 (or 10000)

Hi Andrea and welcome to the forum!

Some things you should check:

- The focus

- Make sure that you are using mm/minute and not mm/second.

- The value of the GRBL variable $30 should match the S-Value Max in “Edit > Device Settings” (probably 1000.)

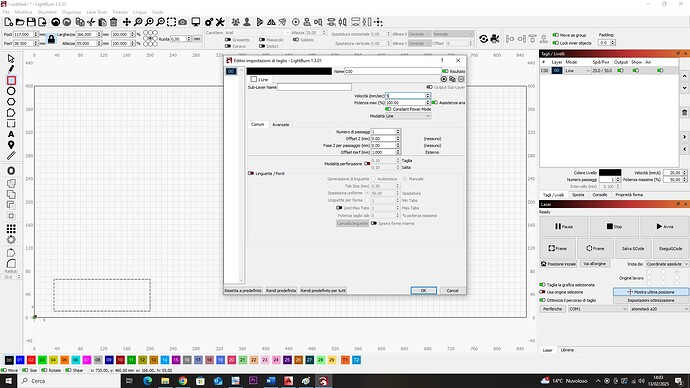

If this does not help, send us a screenshot of the result and the settings you used.

as you can see from the photos the laser engraves but does not cut. in fact it heats up so much that it bends the metal sheet. In the Atomstack document it would say to put the power at 86% and the speed at 50mm/s

That’s very common and expected. You can’t really use a diode laser to cut steel, even if it’s very thin. You will always have strong bending and 20W is not enough power overall. A fiber laser is the better tool here.

You can use diodes, but you will have this bending, and I’d go for 60W or more to cut steel.

so let’s say that the company is somewhat deceptive about the cutting capabilities of the laser it sells. anyway, thank you. is there a material (such as aluminium, tin or similar) that can be cut with 20w?

No. Diode lasers are not made to handle metals. Better to speak, the only metal they can handle is stainless steel. All other types of metal (aluminum, silver, copper, gold, tin, zinc etc). are impossible to use. It’s just physics, wavelengths, and energy transmission. If you want to use metals, get a fiber laser, that is made for metal handling. Stainless steel can be engraved, but usually not cut.

A diode laser is made for organic materials like wood and leather, plus somewhat “natural” materials like slate, stone, tiles (but all those can only be engraved, not cut).

All of them are. And they are exaggerating the capabilities a lot, also for technical data like laser spot size. Most special things they mention CAN be done, but more in laboratory conditions and dedicated use cases. They often mention “can cut 10 mm wood in one pass” but in reality it’s only true for the softest wood available and at the slowest speeds. Not a setup a user would typically use.

For a 20W laser, the maximum I recommend is 10 mm plywood. I guess they advertised with 20mm and more ![]()

That should be $30, not $36, unless Atomstack is doing something truly nonstandard:

Add thermal conductivity. Stainless is a poor conductor of heat, so it can be “marked” with something like heat treat coloring.

Yeah, this is a problem even with lasers designed to cut metal.

Thin sheets will do as they will. Bend and twist with the slightest sideways look…

thank you so much for the help you gave me. my primary objective is not to cut steel, but since it was one of the “possibilities” I wanted to understand if I was wrong or if it was a marketing exaggeration. so I think I am satisfied thanks to your answers.

As you can see, I bought a 20 watt laser from Atomstack a few days ago… IKIER K1 Pro 20 Watt - #23 by parsec and I’m not happy with the performance either, which is significantly different from the advertising.

If you want, we can continue to exchange our experiences. I have now managed to cut 10 mm plywood: Cutting Gears from 10 mm plywood - #8 by Tilman

I will be happy to continue sharing our experiences

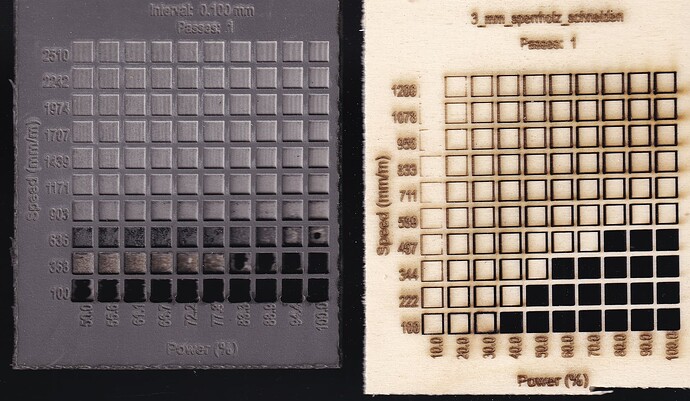

I will also publish my projects in finished creations, so please have a look there too. Here are two material tests:

On the left in the picture, stamp rubber… good experience with 903 mm/min and a performance of 80% (I read somewhere that a performance of over 80% shortens the life of the laser)

On the right in the picture, cutting 3 mm poplar plywood(!): here good experience with 467 mm/min and a performance of 80%

If desired, we can also exchange the g-code files for the material test.

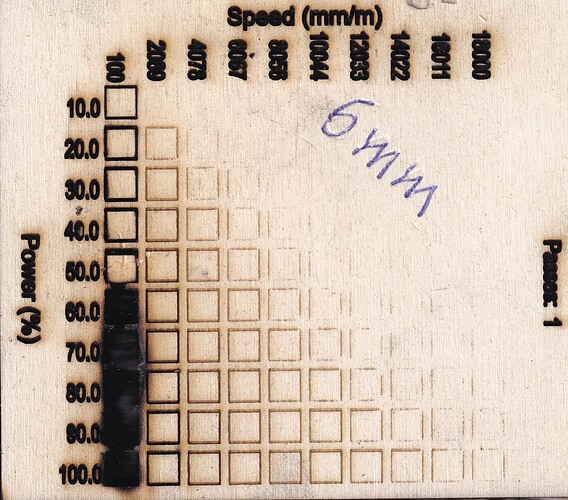

As a warning example, here is my first material test on 6 mm plywood. The speed range was far too optimistic (100 to 18000 mm/min)… so it seems as if you can only cut at 100 mm/min… So I had to repeat the test again from 100 to 1800 (i.e. a tenth of the previous value) mm/min.

What’s missing in those tests is the number of passes. In most cases, it’s not desirable to cut in a single pass. Using multiple passes at higher speeds usually creates nicer cuts with less charring.

I’d use 900mm/min and 2-3 passes in your case.

You are right, sorry, until now i tried one pass only …

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.