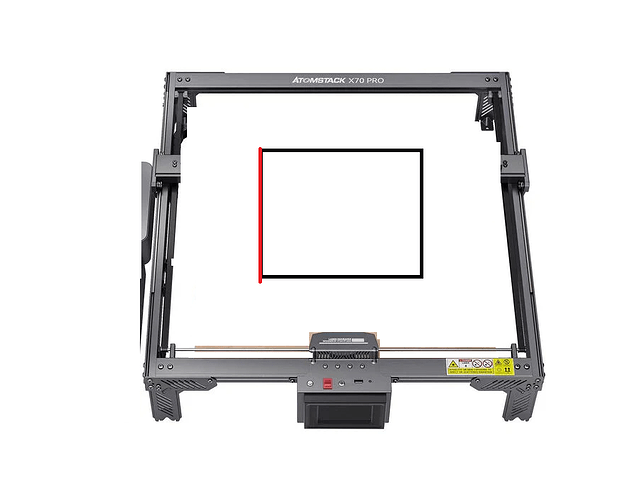

Don’t know that I agree with the cause. Mainly because it doesn’t appear as such to me.

This occurs in both directions, more like you have an intermittent connection occurring. If it does this repetitively in the exact same spot even at different locations in your work area, it’s likely not an intermittent. It’s usually a good idea to remove/replace or give a good wiggle to the connectors to ensure you’re getting a good connection. This is especially true in areas that the wires are moving, which exacerbates the issue.

When you do the circle, both axes are in play if the output is in any directions other than purely X or Y… It’s evident in the circle that it’s unlikely it’s belt tension…

Unfortunately, it’s pretty much impossible to explain how to correctly tension the belts, it just takes hands on time for your brain to figure out what it feels like…

I think this looks more like the laser isn’t lasing when it should, back to a bad connection…

However, I have some suggestions for the belt issue… without power, feel the effort it takes to move the head/gantry. Loosen them enough so you can feel less drag. Do this until you can’t feel a change in drag. Then start the tightening procedure, feeling the drag across that axes… Once it starts to take more effort, you are likely near the best area and probably a bit tight.

This belts are just automotive timing belts and have little real stretch, partially because the have metal wire in them…

My first query was if the laser was moving around the corner or was jumping instead of a smooth movement. I doubt that it’s jumping these areas, which would only leave it’s not lasing in these areas. If it were jumping, it would loose steps and the objects would likely not line up.

It’s easy to fall into the I know it’s this because syndrome when it’s not what you think… When troubleshooting, try to keep a very open mind…

I know it’s easy to do because I do it all the time it’s a human thing

Good luck