Ok… Updated:

I decided to modify the original pen that I cut off my Monport 130W…

Here are the results: (in steps)

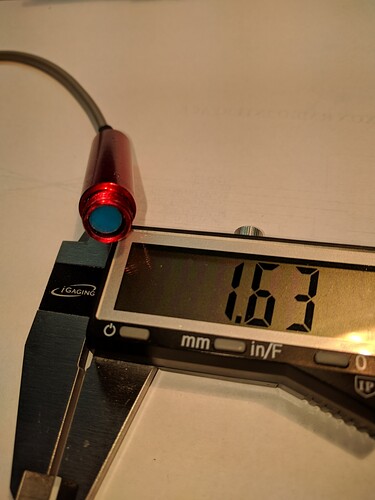

I modified the plunger top that makes area contact with the inductive sensor end (blue spot)

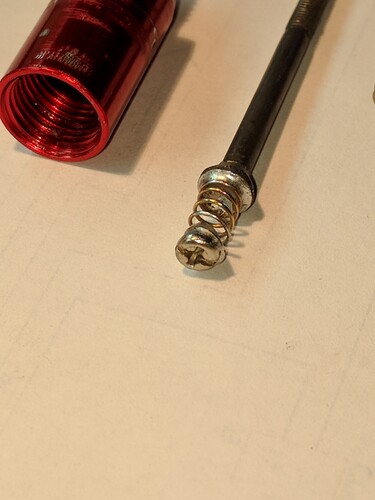

All the parts are shown:

I replaced the cable on sensor module that I had cut off and also

modifed the end of the top pen but opening up the hole to allow the sensor

to be placed in from the top. There was an internal lip that prevented you from just

pulling the sensor module out after removing the set screw…

This made it easy to work with…

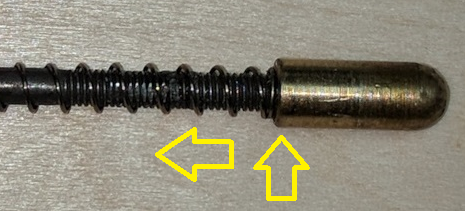

Next I added a spring and screw top, soldered to the top of the original plunger.

the screw top provided enough surface area to trigger the (blue) inductive area.

(this will become clear why it is needed below)

I took a spring from a typical ink pen and cut it and cut a screw top, clean

and soldered both together and them soldered to the top of the plunger at about

8.6mm length. This was experimental, had to adjust it a couple times for optimum length

but settled on 8.6mm.

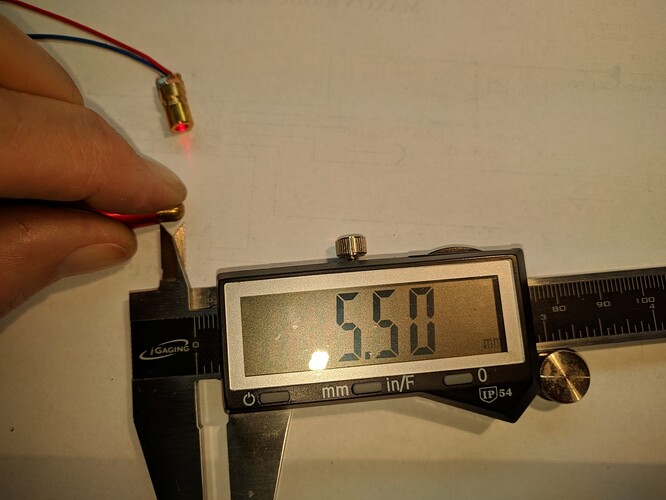

I now inserted the sensor module back into the pen top (the piece with the set screw).

Pushing the module into the top I stopped just shy of about 2mm.

The top of the sensor stopped flush at the top of the pen body top.

Reinserted the set screw gently!

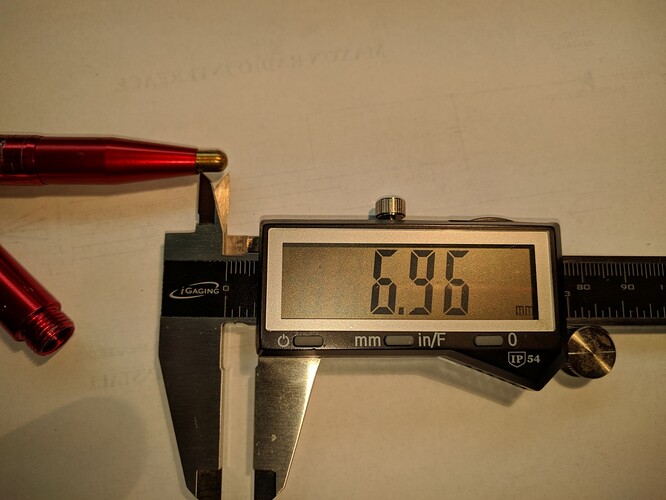

Reassembled the pen, and adjusted the pen plunger TIP by screwing to a length of about 7mm after assembly. this will take some tries to get it right.

I also used some clear fingernail polish as a glue on the plunger threads to keep

the plunger tip from unscrewing and changing position over time.

I used a handy laser module as the indicator for testing, (It was on my work bench)

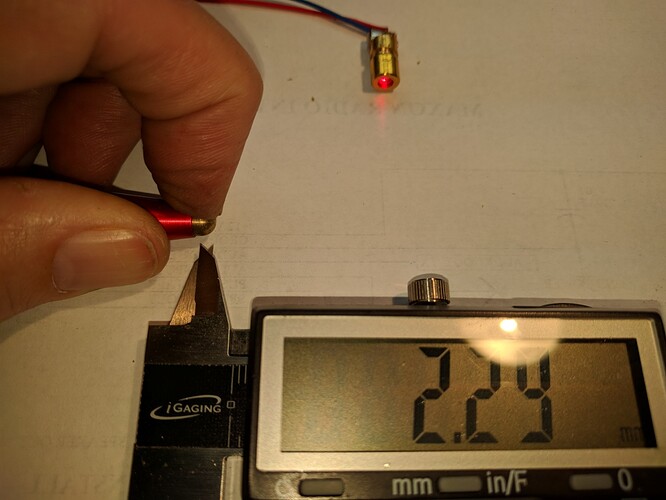

I pushed the plunger into the body until the laser led turned on.

it was about 1.5mm into the body for the ON sense.

A big difference from the original travel, which IMO was excessive.

I pushed the plunger all the way until stopping and it was exposed about 2.3mm.

so this was an extra travel in the On position of about 3.2mm.

this extra throw was needed to allow some cushion in the bed ‘Z’ traveling up,

hence now we see why the extra spring and screw head were placed on the

plunger top. breathing room.

All this made the focus pen very quick to trigger on the initial contact plunging.

And still give some continued plunging with the added spring…

Have not installed on the Monport yet, but will be trying it soon with my hand

on the STOP button

If you like this let me know !

Here is a video in action…you will have to download it and remove the .TXT extension to restore to a .MP4

You can see the actual travel and full travel and release.

Pen.mp4.txt (279.7 KB)

![]()