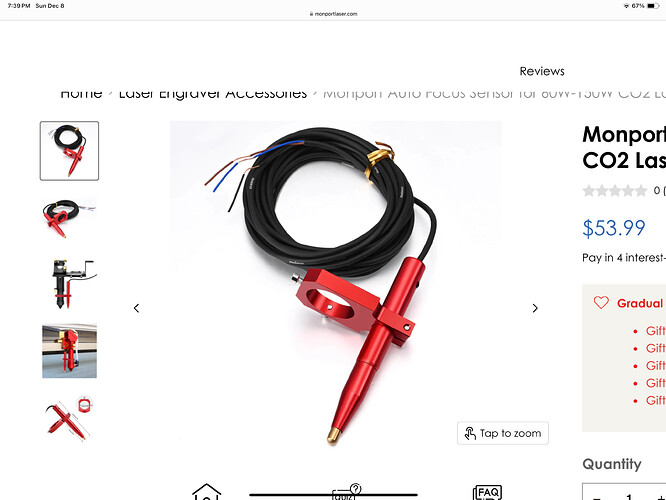

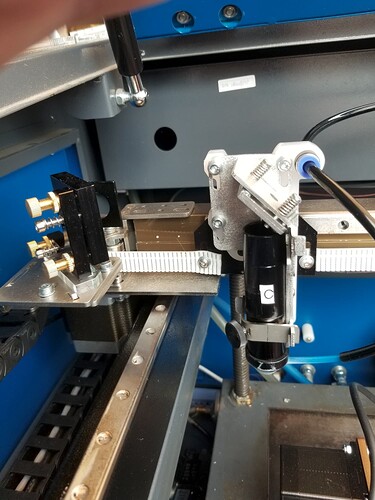

When I first rcvd my new Monport 130w laser, the autofocus pen was set up and working fine ;… I guess…

Did not really understand the need at the beginning, and well… still not convinced that it will make my life better…

But i am willing to give it a try now since I’ve settled on a 3" lens.

Cutting Acrylic…!

I’ve spent a exhaustive amount of time setting up the mirrors over and over

to get the the perfect ‘pulse dot’… Caution engineer at work!

Thanks to Russ’ exhaustive work with lens’, this surely shortened the learning curve.

My main concern, coming from a 3D print background was Z-axis crash.

Watching the bed raise to within mm’s of the laser head was daunting and could easily trigger shingles in most folks familiar with a Z-axis crash…

I tested the Autofocus in Lightburn and tweaked the offset correctly,

Hand Firmly on the STOP button, I watched the Autofocus pen plunger push, push and push about 7/8 of it’s travel, I was 100ms from hitting STOP when

the Z-axis stopped reversed and adjusted to the correct distance from the nozzle. Predetermine from a ramp test earlier…12mm

I have the autopen set to have a 4mm distance off my material, because of the plunger seeming to have a excessive distance before triggering…

While this set up is working well, I am not sure I can get past the trust factor being the plunger takes so long to trigger.

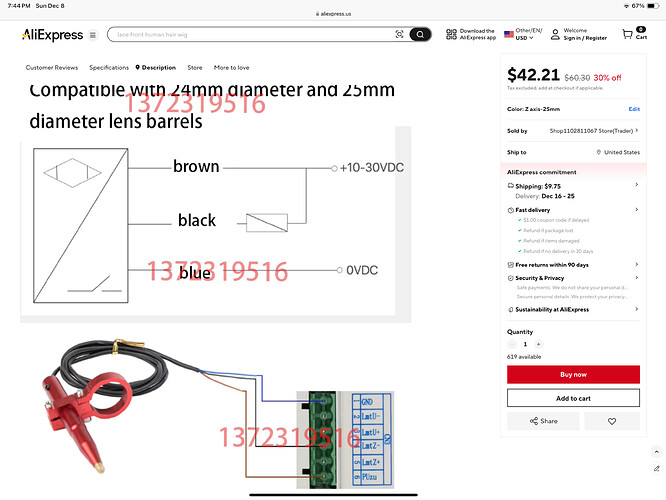

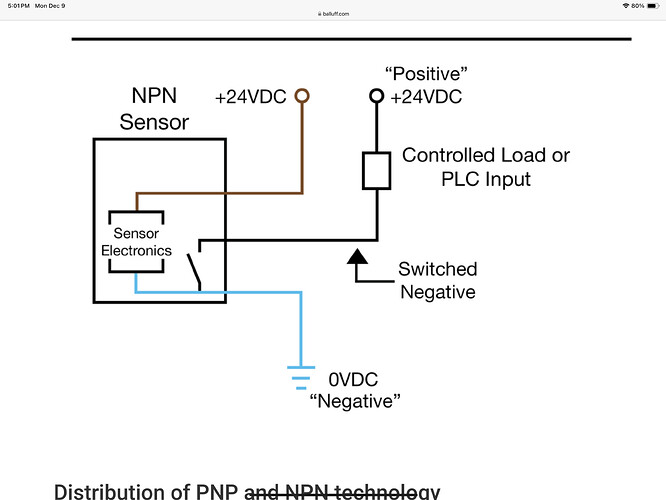

I am sure it is the internal set up, as these are simple prox sensors that I use all the time, but this pen is testing my trust level with each trigger…

I think in the coming days, I need to cut the pen off the cable install a 3 pin connector for easy removal.

Then: tear the pen apart and modify it to trigger just before the midpoint, thus allowing the Z-axis time to turn off and not go past the plungers midpoint…

(in theory)…

Will this help the trust factor… not sure… but I have to admit it was nice setting the material height with a simple Mouse button click…

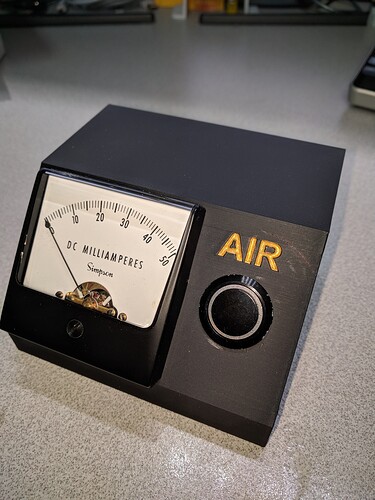

Every day is exciting with a new laser… Unfortunately I find reasons to tinker and modify as with the current meter and air assist ON button…

I found the Light burn Turns on and off the air assist during travel while cutting,

the outter ring of the button Lites Green when on, and I got un-nerved hearing the air solenoid kick in and out, now there may be a Lightburn setting I have not found yet , but I can override the LB software by simply pressing the manual ON button…

And Yes I choose a Simpson meter over the Chinese flavor, old school engineer, hard to move away from quality… And the case is 3D printed, recessed text, Gold paint.

Cutting 3/4Pine

As you can see Top has no scorching using 20PSI air and cant see the botton

which is just as clean with the exception of very few flashback marks from the honeycomb bed. Overall it is nice to see the letters just drop out.

(the board had a ver slight bow as most do)

(cutting some of my Band mates names as a test)

I am not cutting wood, specifically as I mentioned it will be Acrylic,

But the kerf on this was amost null, yes some but it was very acceptable.

(this is what prompted the numerous mirror Alignments)

Forgot to mention these cuts are in the furthest X/Y quadrant, Front Right

on the bed, furthest away of the mirrors…

Ok just a quick mention of this adventure… Wondering what is next…