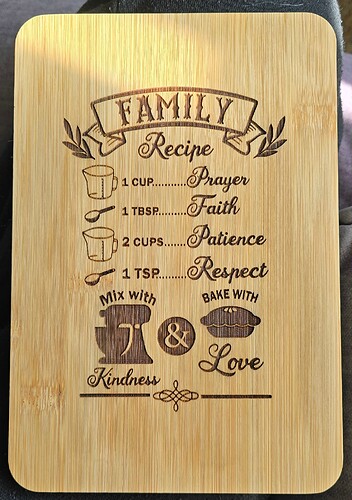

Good evening everyone. I bought a bunch of bamboo cutting boards off of Amazon to burn with my LE5040. This was the result of the 1st burn. I use Lightburn, 45% power, 900 mm/m. Wondering if anyone on here has tried burning these cutting boards, and if so, how to avoid the lines in the grain? More power? More passes? Possibly sand down the board before burning? Thanks a ton in advance!

Two issues I can think of here. First, I see that this part of the grain is very light in color. The light from Diode lasers are known to reflect or bounce off light color materials, not allowing as much energy to be deposited in that location. Second, I think this is also the harder parts of this grain, so requiring more energy to lase/cut/mark.

I would try slowing down a bit, giving more time for the laser to work, and up the power a little as well. Test, test and more testing will help in finding the best results possible.

Personally I would rotate the scan angle or the cutting board 90’ so that the laser travels with the grain of the bamboo this might give it more of a consistent look?

This is a common issue with bamboo cutting boards, as it’s made from lots of slithers of bamboo and they have different densities, so will always engrave unevenly. It’s the nature of the material and there isn’t much you can do about it.

I have done a lot of this type of work on Bamboo and yes it is a problem which is hard to overcome. I try to position my images so as to avoid these changes in grain. Also I choose to engrave mainly in sketch mode with little or no fill in. 1500mm at 75% power on my Atomstack 20w laser machine. Choice of image is all important as some engrave better than others. I buy Bamboo coasters 100x100mm to test settings. When I’m happy go for the larger items.

I’m working with bamboo cutting boards. I do turn them 90 degrees. I’m working mainly with text and some graphics and find multiply passes helps. Like RonClarke said, TEST.

You mentioned the grain. Is it highly ridged…very noticable to the touch?

It is pretty noticeable, but I really like the texture. I’ll coat with something to seal it. If I decide to use it as a cutting board, I’ll have to find a food safe coating.

Wow! super-ridgy, you got the settings worked out right for that one though…looks good.