Thanks for your help John, I appreciate it!

This is what Iḿ getting when I connect:

Grbl 0.9j [‘$’ for help]

Your Grbl may not support Variable Power mode (M4)

If your laser does not turn off between cuts,

switch to the GRBL-M3 device

[0.9j.20160726:]

The other reports:

$i

[0.9j.20160726:]

ok

$$

$0=10 (step pulse, usec)

$1=25 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=7 (dir port invert mask:00000111)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=3 (status report mask:00000011)

$11=0.010 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

$20=0 (soft limits, bool)

$21=0 (hard limits, bool)

$22=0 (homing cycle, bool)

$23=0 (homing dir invert mask:00000000)

$24=25.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

$26=250 (homing debounce, msec)

$27=1.000 (homing pull-off, mm)

$100=400.000 (x, step/mm)

$101=400.000 (y, step/mm)

$102=400.000 (z, step/mm)

$110=500.000 (x max rate, mm/min)

$111=500.000 (y max rate, mm/min)

$112=1500.000 (z max rate, mm/min)

$120=10.000 (x accel, mm/sec^2)

$121=10.000 (y accel, mm/sec^2)

$122=10.000 (z accel, mm/sec^2)

$130=200.000 (x max travel, mm)

$131=200.000 (y max travel, mm)

$132=200.000 (z max travel, mm)

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

?

<Idle,MPos:0.000,0.000,0.000,WPos:0.000,0.000,0.000>

ok

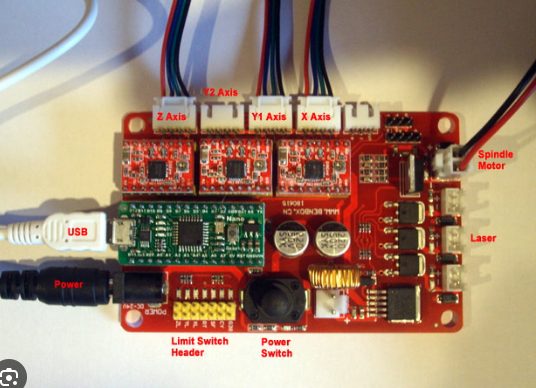

I see that the nano on the controlboard is a clone, I have tried flashing it but that didn’t work unfortunately. I tried that with the Arduino IDE and with the Xloader. Both times no error messages but also no good result…