After swapping out the OEM head on my OMTECH ZF2028-60, for Russ Sadler’s lightweight version, I ended up with six different “C” series tube/lens/nozzle combination to choose from. I still have one empty tube left, and I was wondering, is there is any value in getting a 3" or 4" focal length lens? Currently the longest FL lenses I have are a D20 FL63.5 GaAs, and a D20 FL63.5 ZnSe. I mostly engrave Acacia cutting boards using Russ Sadlers compound lens kit (which is phenomenal), but I’ve started cutting some thicker acrylic (4 to 6mm) and plywood for other projects and I’m struggling with the thicker materials a bit. I haven’t been able to find much information on when it’s appropriate to use a longer FL lens, so that’s why I’m asking the LightBurn brain trust.

Here is a decent article that explains the differences:

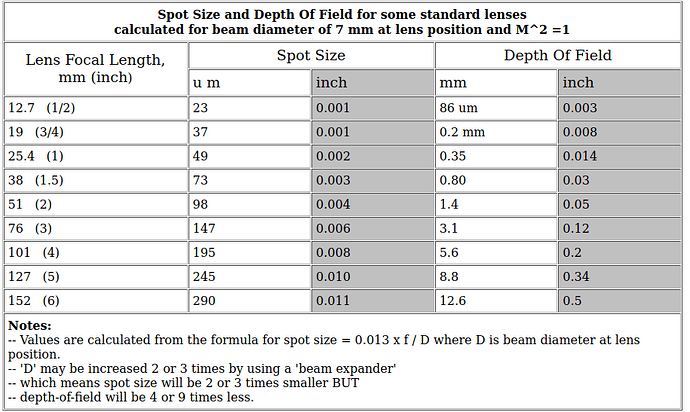

Long lens, large depth of field, larger spot size

Smaller lens, smaller depth of field, smaller spot size.

Check out the chart. Using 6mm material the 4" (101.6mm) has a depth of 5.6mm not enough to maintian a good beam through the material. If you set your focus to 1/2 the material thickness then you only need 3mm on each side. It’s still 6mm but the beam center at material center will put most of the power is where you need it.

Make sense?

I’ve done work with the compound, then switched to the 4" and ran the cut… works great. With this mount system, lens positioning after a lens tube change it’s very accurate.

My suggestion … pick one up they aren’t that expensive, then you’ll know what works for you…

![]()

I couldn’t make up my mind whether to get the 3" or the 4", I figured you would chime in and give me a nudge in one direction or another. Thanks ![]()

I use a 4 inch lens for nearly everything. Have not had the need to switch to shorter FL for a long time.

4” lens are fine except you still need to get air down into the cut. In my case I need a long nozzle which is difficult to find. My attempts to print one have now worked out. It would be interesting to see how others supply air to long lens.

Like this…

Using the tip for a cut, 4.5mm between tip, for high pressure and 17.8mm for an engraving tip for low pressure.

![]()

The Cloudray 101.6mm lens is on order and I’ve got both the 18mm and 30mm nozzles in the spare parts bin, so I should be G-T-G when the lens gets here. Thanks for the info (and image) Jack.

Remember … when you change lenses, like material changes, the kerf will also change.

![]()

That would work Jack. Do you recall where you got it?

If you mean the nozzle, it was from Cloud Ray as is the C series lens tube.

![]()

Can I ask where you bought your Russ Sadler LW head from as it is not on the Cloudray website and I can’t find any other link to it? Many thanks.

Might want to look at this post or thread…

![]()

Jack’s the one that got me interested in switching over to Russ’ lightweight head. I installed it on my OMTECH ZF2028-60E. Jack is the resident expert on the subject, but I am more than willing to share my experience with what I went through putting it on my machine (you can buy the adj. head mount from Cloudray). You can reach Russ by email at removed…

I removed his email from your post… the bots have a field day with them… I think I had pm’d him Russ’s email… Hope you don’t mine…

![]()

I’m sorry Jack, I wasn’t even thinking about that. Thank you for having my back. I will be more careful in the future.

No perspiration…

I believe you know how to pm, that’s probably the safest way to ship around personal information.

Thanks for being a positive addition to the group.

![]()

I do. I forgot how evil the internet is, and the last thing I want to do is cause Russ any grief. I’m going to put a sticky note on my monitor so I don’t forget next time ![]() .

.