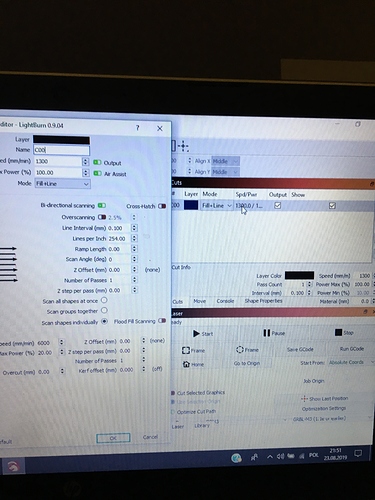

$$

$0=10 (step pulse, usec)

$1=25 (step idle delay, msec)

$2=0 (step port invert mask:00000000)

$3=3 (dir port invert mask:00000011)

$4=0 (step enable invert, bool)

$5=0 (limit pins invert, bool)

$6=0 (probe pin invert, bool)

$10=3 (status report mask:00000011)

$11=0.010 (junction deviation, mm)

$12=0.002 (arc tolerance, mm)

$13=0 (report inches, bool)

$20=0 (soft limits, bool)

$21=0 (hard limits, bool)

$22=0 (homing cycle, bool)

$23=0 (homing dir invert mask:00000000)

$24=25.000 (homing feed, mm/min)

$25=500.000 (homing seek, mm/min)

$26=250 (homing debounce, msec)

$27=1.000 (homing pull-off, mm)

$100=80.000 (x, step/mm)

$101=80.000 (y, step/mm)

$102=400.000 (z, step/mm)

$110=5000.000 (x max rate, mm/min)

$111=5000.000 (y max rate, mm/min)

$112=5000.000 (z max rate, mm/min)

$120=200.000 (x accel, mm/sec^2)

$121=200.000 (y accel, mm/sec^2)

$122=200.000 (z accel, mm/sec^2)

$130=5000.000 (x max travel, mm)

$131=5000.000 (y max travel, mm)

$132=5000.000 (z max travel, mm)

ok

Thank you so much for helping