Is anyone have problem with measurements after update, on latest version of software? All my previous project what i save have problem with measurement’s after update! Doesn’t fit any previous measurement, and dimension what i try to cut its different from dimension what i wont.

Anybody with that kind of problem?

Can you provide an example of the type of problem that you’re seeing with measurements? And to be clear, are you referring to overall dimensions in general or something with the measurement tool?

I will wright to you steps what i perform.

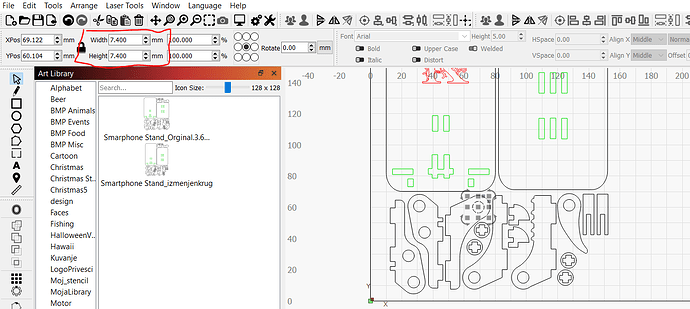

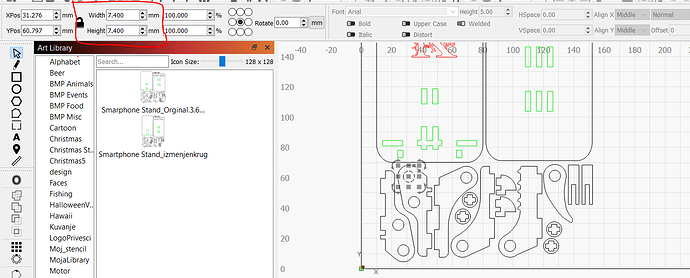

In my art library i have some projects with saved measurements.

I put that projects on screen and check values, of circle, change value, all circle is same value, and the value is not the same what i choose, and what i get on final, when i start cuting.

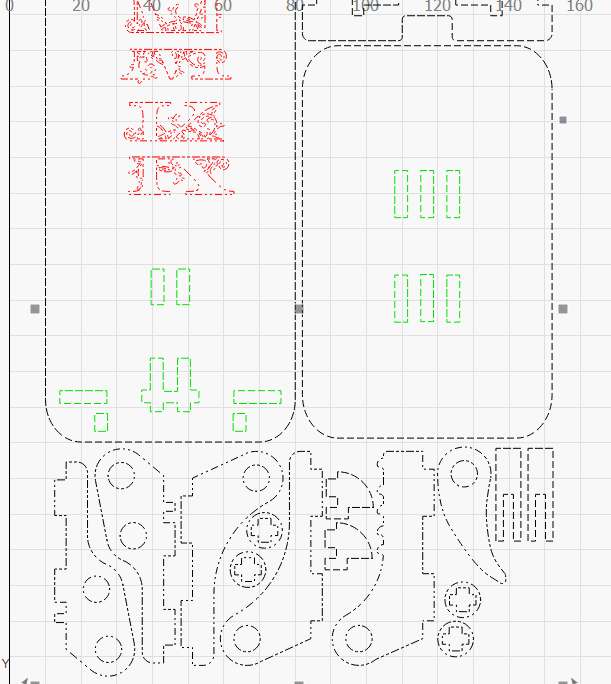

I will provide more picture, to see that something is wrong.

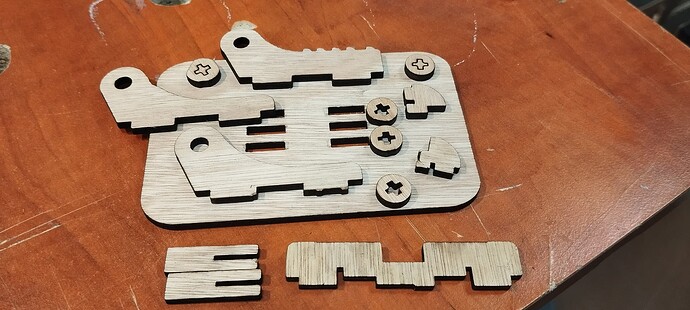

and when you see final result, you will se that some circle is different, dimensions, also some of cut pieces, is different tabs, and everything is mess up, and i checked all dimension in lightburn is correct, something is wrong with new version.

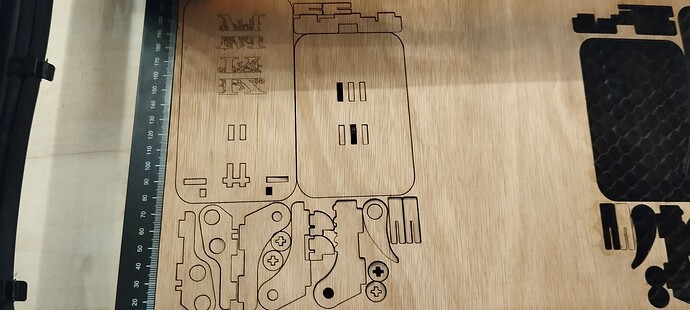

This pieces is correct dimensions, and measurements

And this pieces is mess-up everything is different, from what i choose in software.

This doesn’t look like a software issue. This looks like a mechanical issue.

Are you saying that if you downgrade and cut with the older version that the issues are not there? Or are you comparing old cuts to new cuts?

I say that i didn’t have any issue when working with older version, after upgrade i have that problem.

I don’t know how you conclude is mechanical issue, do you know from before someone who have similar problem, if you know, please let me know how is solved?! I will downgrade this version and i will try after that!

I haven’t concluded. I’m saying that’s what it looks like based on existing evidence. Also, knowing what’s changed in the upgrade this isn’t the type of artifact you’d likely see.

Yes. Very frequently. A search on this forum will show you many similar situations.

Yes. I think this is a good validation. Many times people experience an unrelated issue concurrent with an upgrade. This can lead to associating the upgrade with the problem when the problem actually lies elsewhere. This may or may not be your situation but good to confirm to reduce the number of variables.

I’d suggest doing a thorough mechanical review of the machine. Most typically, a non-round hole is caused by backlash. For common diode lasers this is generally associated with the grub screws not being properly secured to the stepper shaft. Check that the grub screw is firmly tightened against the flat of the stepper shaft. Also check for proper belt tension.

But do a thorough check to see if there’s any play anywhere in the mechanics and try to eliminate them. Do not overtension anything though. Things should still move smoothly.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.