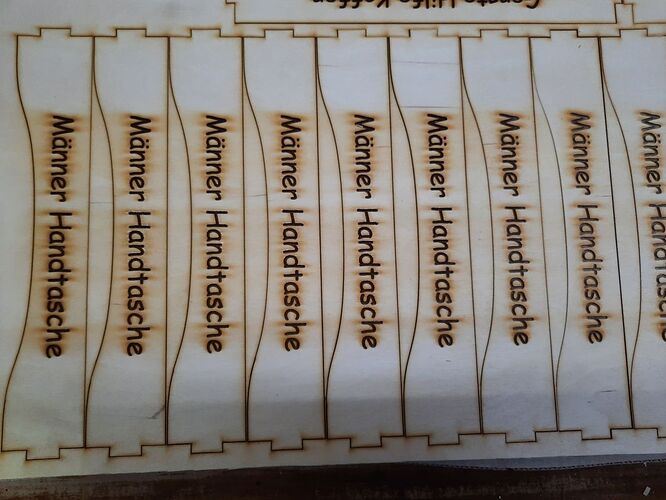

Hi. I have a lot of Burning Traces when I cut text with line - 200 mm/s - 50% max power - 20% min power on a 100W (nominal) China Laser. When I do this on material already coated once, I get the effect as a glossy brown smear like glue. So I tried to burn on the original material and got the below result. As I don’t believe this is how it should be, I must do something wrong here.

I appreciate any hint how to avoid or minimize this effect.

This could indicate that you are using a lot of air through the nozzle. I would try to reduce it to a minimum and in turn increase extraction to its max. You have not mentioned your settings, but with me it helps to engrave as fast as possible with as little energy as possible. When I look at the edges and they are too dark or leave soot on a piece of fabric or paper, I know my settings are not right. In fact, they should have the same color as your surface has in your image, maybe a little bit darker. (up to 4mm on BB, by my machine)

PS. “Gerste” … like hops and malt?

(3mm HDF)

Hi Bernd. Yes, Gerste = Barley. It’s playing with words as “Erste Hilfe Koffer” means “First Aid Pack” and it’s for a Beer Caddy. Good guess.

I want to engrave a bit deeper, otherwise it doesn’t look well when the wood is colored. You can see the difference here with the text on the handle and the hop on the side.

I’m always using Air Assist and can only switch on or off in Lightburn. Maybe I will try without but I think, there would be a chance of fire ?

And what do you mean by extraction ?

It certainly does not look bad, the hops could use a little more depth, but overall your beer crate is very fine.

By extraction I mean the fan itself which sucks the smoke out of the closed laser machine.

Do not drive completely without air on the nozzle, as the lens will only get dirty very quickly. But reduced, somehow, to a minimum helps in reducing the sticky gas residues. (engraving)

In your photos I can see that you have very fine cuts. So these parameters are definitely ok. When engraving, the result is sometimes nicer if you run two laps with a little less mA.

May I ask where you bought the bottle opener?

Oh yes, the extraction fan… I replaced the china crap with an 48db silent fan, but it’s a bit less extraction with it. Maybe I will look again for a similar one with more power. I will see if I can lower the air at the nozzle itself.

Beer Opener: 10x Wandflaschenöffner Bieröffner Flaschenöffner Wandmontage Wiederverwendbar tw | eBay

I’m always using Air Assist and can only switch on or off in Lightburn.

Install an adjustable ball valve into the air line that supplies your laser’s head. Something like the following:

https://www.ebay.com/itm/373594059821?hash=item56fbf0f42d:g:AC4AAOSwhOFgrz0p

https://www.ebay.com/itm/182589155579?hash=item2a832968fb:g:dHsAAOSw2hhciyre

I have a screw on the air assist and I closed it a little bit. The result was a bit better than before but not too much. But I have found another solution that works so brillian…

Ideally I wanted to engrave on the coated wood rather than the raw plywood, as this would be another step in the process. The problem was really the sticky bit that came along with the engraving. Now, I tried a Nano Magic Sponge (like this: schmutzradierer - Google Search), a little bit wet and in 5 seconds it took away the condensate but left the coat as it is. Looks super nice.

This is the solution for a number of problems I had with engraving and I’m super happy about that.

You can see the difference here: