Ok people a query about extractor fans for the Lasers…

Anyone have any thoughts on using a range hood…In NZ can get one for 160$… (98 USA $)…

Some have charcoal filters some don’t but can also be extracted to the outside, and you have a light above the Laser…

Inquiring minds need to know your thoughts on this…

Range hoods have fairly small fans in them, and I doubt would pull anywhere near enough cfm’s to be of use. But, you’d have to look at your requirements and compare to how many cfm the particular hood pulls to see if it would be sufficient or not.

IMHO, I think air flow through the machine is critical. You want it to move across the engraving area, preferably in a direction that allows debris to pass before you lase it.

If you have an image scanning from the front of the machine to the back, then that’s how the air should flow. The least amount of changes in air direction will give you the best flow through the machine.

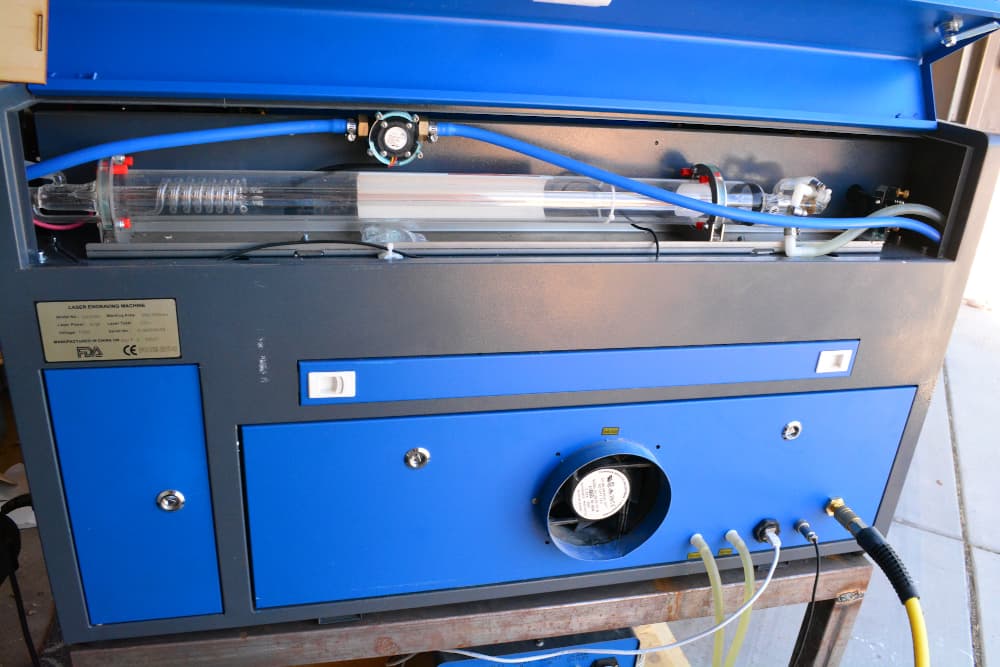

This is cutting 5mm sub flooring with the original factory fan in my China Blue with the lid fully open. The fan is in the rear center of the machine. This is also the original air pump… it’s sitting 5mm above the steel bed. It works much better with the lid open just about an inch.

This is the reason I pitched the honeycomb. The air flows not where you need or want it to flow.

Get out the thinking cap… if you use something with a carbon filter, it will help but most of the bad gasses will still get by them … if they don’t, you might want to buy stock into the carbon filter company since you end up putting out cash for new filters quite regularly…

Good luck, this is an issue.

![]()

Yes Merlin. Would like to choose fans light with cheap prices? chose here.

I’ve got a 200cfm rated inline blower that’s probably getting me about 180 with short pipe runs and a bellmouth. (I really should put my anemometer to it and see) It’s exhausting a 30cuft enclosure and I consider the resulting exchange rate barely sufficient.

Done over, I would probably opt for more like 400cfm, high static rated, with 6" duct.

Although, as Jack said, getting the air OUT is the easy part. Getting the clean air IN is much trickier. Moving clean air across the top of an enclosure is about half useless.

FWIW.

Sorry for the long break (Health)…

The Range hood I’m looking at states “Cubic Meter/Hour 440” that from what I found on an online converter = 258.974 Cubic Feet/Minute…

If that is the case wood that not be enough for using a home laser at no more than 30 minutes at a time…

Help an old man understand, that never had any schooling in such things…

Merlin…

That sounds adequate to me, Merlin…assuming this is to be used as part of a full enclosure. If literally a hood suspended above the working area, it may not be enough depending on surrounding air currents.

Hey Chris, I only have a 3 square meter tool shed that is for storage and Laser so so should not be a problem, I can run an outlet through the roof if needs be…But that wood require a rain proof hood…

Merlin…

Hi Merlin,

I know it sounds a bit over-simplistic but have you tried just using a shop vac? All you would need is a hose long enough to set the vacuum outside while you run the laser. My Missus has a friend who has her laser set up on their veranda and she uses a cheap ozito shop vac to move the smoke away from where she is working.

Another option would be to use one of those shower exhaust kits from bunnings. They come with 150 mm hose and an inline fan motor.

Thanks Rob …I was going down the shower exhaust fans but though it was not strong enough…

Shop wood be simpler but too noisy for me…

I have a fan that moves warm air from room to room that might work directly behind the laser…hmmm…

bit wet and windy here at the moment will get onto that when it warms up again…

Thanks for the suggestions…

Merlin…

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.