Looking for someone to make files to spec for guitar and bass pickup flatwork to import into lightburn. Someone familiar with guitar would be helpful. Holes need to be correct to accept parts.

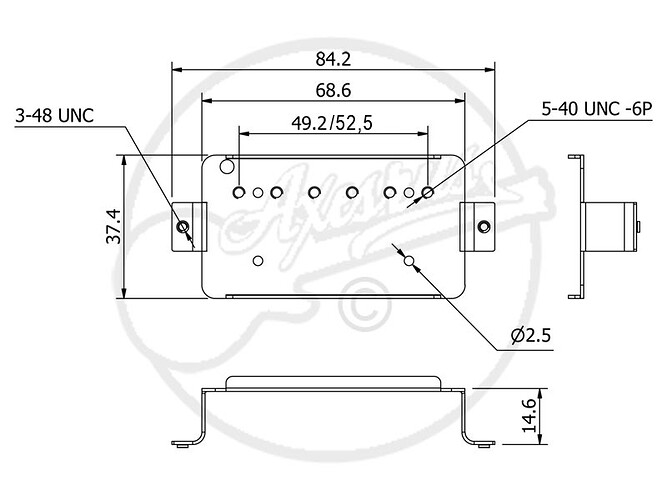

The specs shown in picture are representative of a metal stamping, not a flat piece of vulcanized fiber, flatwork needs no legs.

In picture of completed pickup you can see the universal nature of the baseplate purchased at Mojotone. I would like to have a file for each style of build, Standard Gibson 6 screws and a slug coil, dual row screws in various string spacing 49.2mm, 50mm, 53mm, 7 and 8 string. No holes in middle to have room to burn logo on baseplate eliminating need for sticker label.

To start i would like to make 7 string baseplates since they are not available. If the file cuts correct and the parts fit onto the baseplate correctly move on to other models. There are many Humbuckers to single coils, bass, etc. You can see in the picture of the finished pickup how precise everything fits. Machinist style accurate.

I apologize for my frustration and poor attitude

I apologize for my post.

You said someone made the file but “it’s not accurate” - in what way? When cut, are the dimensions off? If so, have you accounted for the Kerf width of the laser when cutting?

Drawing the shape is the first part of the process, but no design you get from anyone will output with correct dimensions unless you account for the thickness of the cutting tool.

And please, keep things civil folks.

I apologize to the Forum for coming on while extremely frustrated. I should have waited until i was in a better place. I did not mean to offend the creator or users of light burn. I apologize to Kobild and JMichael specifically.

If it would help, I can put you in contact with someone that uses a laser to make guitar parts. I think that he makes bridges but he may be able to design what you want. Message me privately if you are interested and I will give him your contact info.

Mike

Don’t mention it. We all get frustrated and I in turn will apologise to you for my response.

A lot of us here use lightburn on a daily basis and become a little protective of it.

Hole diameter needs addressing. Maybe that Kerf mentioned. Not a big issue, I’m sure corrected easily. The fiber really needs to squeeze on the pole pieces so the pickup does not fall apart. On left is the quick lightburn cut with a .187 pole piece inserted (very loose) next to what comes from the guitar parts place on the right. These pole pieces are pressed into the fiber

As you say, some kerf adjustment should help with that fit. A bit of trial and error with sample parts should pretty quickly get you zoned in on typical kerf adjustments for specific hole sizes.

you could always just adjust the size of the hole instead of the kerf. then it will adjust the hole only and not the rest of the cut layer.

I work a lot in cad, the lines and dims will be exactly the same as having drawn it in LB, the dead accuracy will need to come from adjustments due to the thickness of the cut. If I’m cutting pieces to fit very tightly I have to change the measurements on the file by 0.2mm on everywhere where the cut is duplicated on another piece that has to fit the 1st cut.

So just getting someone to draw your item in CAD will not solve the issue, unless they draw it with the kerf taking into account.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.