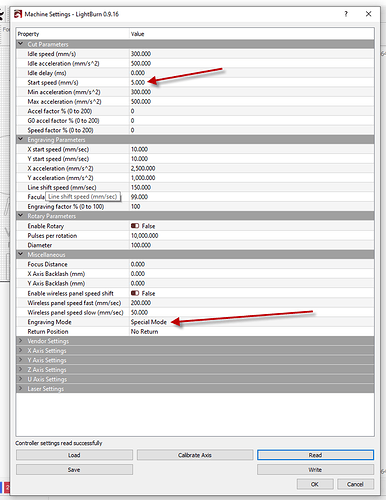

Maybe try changing your Engraving Mode from Special Mode to Common Mode:

From Ruida:

Scanning Mode: it is divided into general mode and special mode for option. If special mode is used, the laser power should be increased. The smaller the speckle percentage is, the more the laser power reduces. The laser power to set should be larger in order to reach the same scanning depth. The purpose to select the special mode is to make the laser light at high power and short time. On the depth scanning the effect that the bottom is flatter is obtained, but it should be noticeable that if the speckle adjustment is not appropriate, it can achieve this goal. If the high power remains short, the lighting mode will

influence the life of the laser. The system will default the selection of general mode.

Side note: I noticed on your picture you have a line layer set to 4mm / sec but your controller’s cut parameter for start speed is set to 5. You probably want to lower that controller parameter down to whatever your lowest speed is that you will use.