The reason for me wanting to change the controller is basically because i use lightburn to do all my laser stuff and its not supported trying to send it to lasersoft. If there was a easy way to be able to do that i would keep the controller

Unless you’ve somehow mitigated Laser Power Supply current I’d suggest not running at full power as you’re likely running higher than what the tube is rated for. This will lead to premature tube death. Do you have an ammeter or some way of knowing current draw for the tube?

What units are you using for speed?

First make sure the mirrors and lenses are clean. Then make sure you have good alignment. Neither of these will fix damaged or worn equipment but you may be leaving a lot of performance on the table if these aren’t in good shape.

Can you not export files and import into Lasersoft? You’d still have to address cut settings but all design work could potentially transfer.

I checked the mirrors and they look bad, like the reflected surface has a dimple.and the focus also looks like its had a hard life as well. I checked the laser is hitting the mirrors in the centre. I do have 1 question on how to know how far away from the material the laser should be

I briefly tried. I saved my file from lightburn and then went to open it in lasersoft and the file cant be found. Im guessing the format of lightburn is different to the files lasersoft can read

This depends on the focal length of the lens. If you’re not aware of the lens that you have then run a ramp test. That should give you a sense of ideal distance from lens to focus.

The native .lbrn file is for sure not going to be supported. But Lasersoft likely has a list of compatible import file formats. I would expect DXF at a minimum.

You can export SVG, DXF, and AI formats from LightBurn. See if one of those formats is available for import in Lasersoft.

Yes that is what i have done. Wasnt sure thats the right way to do it

Ok i will try that

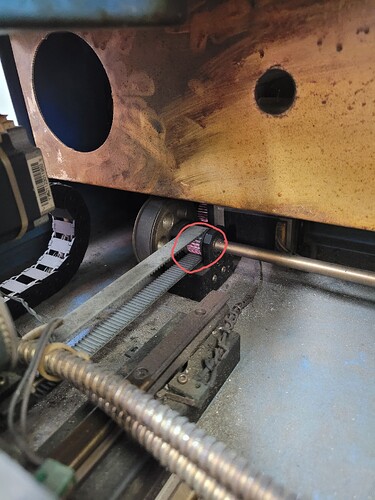

So i just been having a look to see if i can see anything weird looking and i found the x arm was loose and i have noticed if i try to move the y axis there is about 1mm play back and forth. The stepper motor isnt moving

This is the part that has play in it. Is this normal ?

For the speed its what is set in lasersoft

From what little I can see there, it looks like a well built machine. I can imagine it taking quite a bit of time and money to modernize it, but the results may well be worth it.

No. You should have no visible play. Check how the gear is secured to the shaft and remedy the backlash.

While you’re at it I’d suggest a very thorough cleaning of the machine. A dirty machine is inviting all sorts of problems.

It should show you the units. As in mm/s or similar. Without knowing the units the numeric value is somewhat meaningless.

Let me check tomorrow.

So i had a look at the tube and its a 80/100w

What kind of speeds and cutting depths should i be expecting? Would be good to have a idea of what it should be doing and compare how its performing now

Yes thats on my to do list. I started with cleaning the bottom of the machine which was crazy bad. Also alot of the frame holding the bed was either loose or not connected straight. The bed was really not flat from 1 side to the other. So i took it all apart and made it right. This machine was from a education centre so i know its had a hard life

This is very hard to say. I have an 80W tube that’s probably more like a 70W tube. I can cut 1/4" plywood at roughly 16 mm/s at 65% power using a 2.5" focal length lens.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.