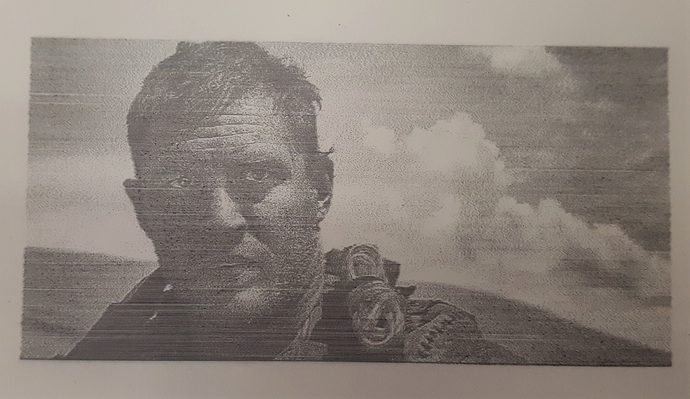

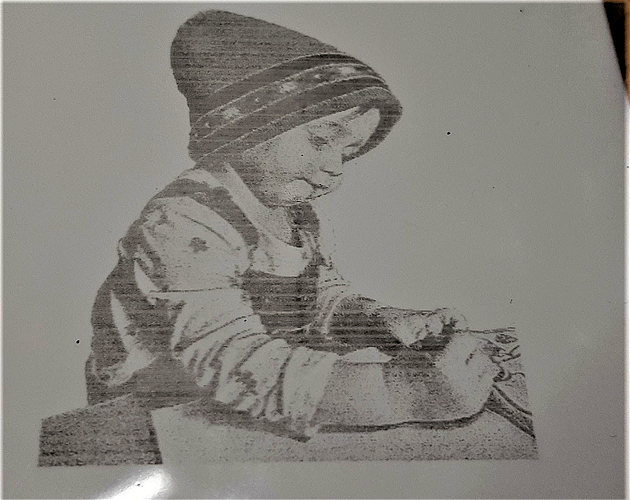

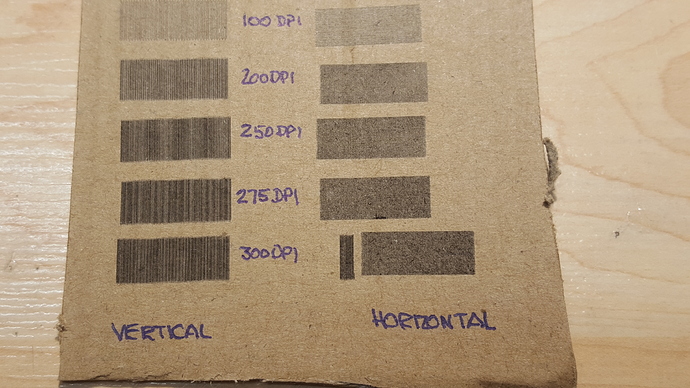

Good Morning…trying to etch grey tile painted flat white…4x2 inches…first photo was using 200 dpi and line intervals very prevalent…on this one I used 350 DPI and I can still see the lines…any thoughts/suggestions…Eleksmaker 2.5 watt Diode…Mana SE …grbl1.1e…jarvis dither!

I suspect this is mechanical, because it’s not very consistent. Check to make sure the Y axis rails are completely smooth and clear of debris, that the Y belts are snug, and the rollers move freely and have no indents. Any one of these things could prevent free movement of the Y and cause that.

The giveaway here is that most of these lines do not run the full length of the image - the two white lines on the upper left, for example, do not appear on the upper right.

Thank you…will disassembly/clean/reassemble and align

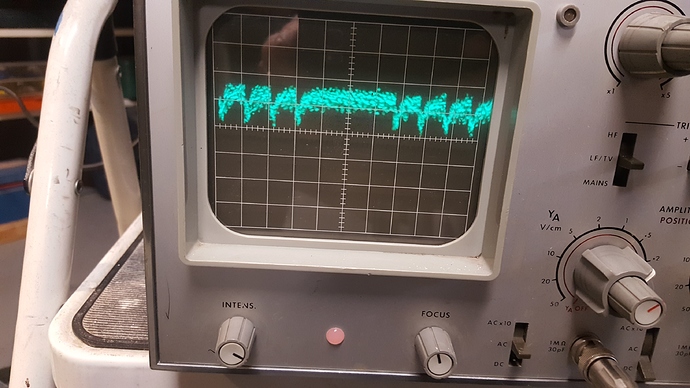

well I pretty well pulled all my hair out…I have dis-assembled …new belts …adj stepping motor current…cleaned track…cleaned/checked wheels …cleaned tracks…aligned everything…cleaned lens…smooth rolling…etc…still the problem exists…line “bands” are repetative in 1mm intervals…checked power supply 1 volt ripple at 1000 Hz…stepper motors are 80 steps /mm which is 0.0125 mm which is 2000 dpi…( i.m thinking for my controller this is way too sensitive…low torque)…change micro steps to 8 instead of 16…!replace y stepper module???..maybee change micro steps to 8 instead of 16…something happens every 1 mm and it is not dependent on length of run…almost like the stepper loses steps every 1 mm …timing???

20190325_163031|690x388

Are the Y rollers and bearings clean? No binding in them?

Already to see if the problem is hardware or software (and before disassembling everything…): does this image at the same resolution give the same result with another software?

will try T2…,

Tried T2 same issue…tried swapping stepper boards…no change…tried changing micro steps from 16 to 8 …no change…tried horizontal scan…NO Problems!..connected micrometer to y stepper…intervals .01mm…video;d and documented step intervals…13-5-15-6-4-5 …something’s amiss I,ve tried everything I know…controller board ???

Have you tried swapping the motors from x to y?

Another thing you could try is to disconnect the motors from the machine, put some tape on the spindles to make a flag and see if they make uniform movements.

swapped motors swapped stepper controllers…put a tooth pick on end (lools like a clock)…started a scan and watched movement…it was not exact each time …every few movements there would be one where it would just barely move then it it would move “like a clock” for next few then sometimes almost like a double movement

Did you do the “clock” test with the motors removed from the machine?

yes…and and I could see variations in distance moved…also put a toothpick on ends connected to machine…and you can see variations…gotta be a firmware issue in the “clocking”