So here is picture what i try to cut/engrave.

And here is results…text is something like a 5mm off from where is it should be.

Everything else seem to work nicely

Everything else seem to work nicely

If you use the Preview feature (Alt+P) does the result look like what you have in-hand?

What are the values you are using for start from and job origin?

These can/do effect the output position…

![]()

Start From:absolute coords

Job origin is upper right…

How to try another positions in weekend…

Often when we see this it’s caused by two parameters.

Scanning offset, in Device Settings is incorrect or disabled.

Bi-directional engraving is turned off and only showing the incorrect Scanning offset in one direction.

Please check these two settings and confirm that they are both present and that you have performed the outline cut as four vector lines.

This may be worth review:

Problem was with origins… and how to say im still little confused with those…too many origins in this software ![]() well maybe i understand someday. Now i try to learn more about those thinks. But thanks for scanning offset adjust thing. i was thinking that too because the letters outline looked juuuuust little bit like saw so now i got that much better

well maybe i understand someday. Now i try to learn more about those thinks. But thanks for scanning offset adjust thing. i was thinking that too because the letters outline looked juuuuust little bit like saw so now i got that much better ![]()

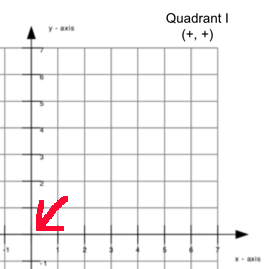

There are two types of origins with cnc machines…

One is where the machine locates, usually 0, 0. This defines the quadrant that your machine operates within.

All machine have a 0, 0 or origin… marked in red in the coordinate system…

If the machine homes (0, 0 origin) at the front left, it’s operating in quadrant I. Down or left is out of the work space. Up and right limits are defined within the firm/software… as maximum travel of the axes.

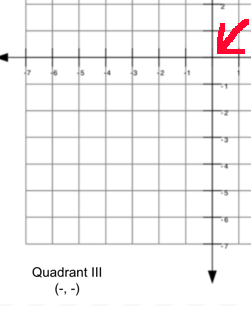

However if the machine homes at the back right, then you are in quadrant III… where up and right are out of the work area…

I won’t elaborate on the others if you follow me here…

For the software to know how to generate the proper code, it uses the origin in the device settings to know what quadrant your machine is using…

The value of start from tells the software where the current 0, 0 point is… it can be absolute coordinates, using the values directly… user origin which is some user set point within the workspace. The remaining current position is where ever the head is when the job starts…

Even more control of the generated code is by the selection of the job origin… this is the 9 dot selection. This setting is used to identify where the job itself is located…

If you assume a square. If it’s set to the upper left dot, the job will be generated to the right and down… if the center, the object is equally around the center point…

I use center left quite a bit for mugs… I can align the center of the design to the cups logo when it’s in the rotary…

I use upper left in most of my general lasing… so the head is up and left of where I’m going to place the object…

You’ll pick it up, if for no other reason you have to, give it time … ![]()

Everyone struggles with this… This is the basics of the roots of the two origins and what they mean…

Make sense?

There are a number of things that can complicate this… but generally this is how the two work.

Good luck

![]()

![]() Yes i understood origin of machine in very first time i setup my laser but job origin would not make any sense because im telling LB where the job is by putting “job” in x,y and if you draw with LB itself it gives every draw own origin and thats make my mind splitting even more…

Yes i understood origin of machine in very first time i setup my laser but job origin would not make any sense because im telling LB where the job is by putting “job” in x,y and if you draw with LB itself it gives every draw own origin and thats make my mind splitting even more… ![]()

And im not sure anymore should i use absolute coords or current position… but i think this threads can be closed and maybe i open new one after i got some education from youtube ![]() and more freetime from jobs

and more freetime from jobs

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.