I was researching that product to find out the good/bad. Thank you as you simplified that for me!

It is a great product and concept, the only flaw is in the applicator. The spray bottle clogs up rather quickly. It was very cheap for the Tio2 powder and I used alcohol available at Walmart.

There is a couple of massive threads on using TiO2 mixed with things other than alcohol. They claim it dissolves in alcohol, but it doesn’t appear that way.

I live in the desert SW and the humidity is very low and the temperatures rather warm, so alcohol disappears quite quickly. Seems to plug up stuff…

I think I posted the link back near post #2

![]()

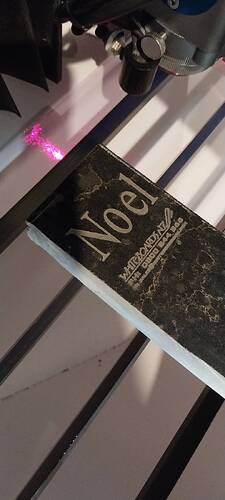

Hello David, for what it’s worth I know my VyTek 40W Co2 laser works on granite, however I’ve not done any in recent years. But I tested this exact material just recently on my AccTek 130W Co2 laser as below. I’m not sure what power setting this was done with so will have another try at 14%.

Most of my work is using porcelain (ceramic-on-steel whiteboards), feel free to message me about this material any time

Thank You Jay. I knew upfront that my 20w blue diode is very limited but given the nature of the original request too me, I thought I’d at least “try”.

The only reason I’ve not proceeded past the initial acquisition of some porcelain tiles pieces, cheap stuff, is that I’m waiting on a usb 3.0 cable extension to arrive so that I can control the machine out in the garage from my computer room which is obviously, inside. Way too hot out there! I’m in Arkansas where the heat is plenty bad but we’ve got terrible humidity too.

Go to a creek bed and pick up rocks to test on. Get smooth flat stones

A very cool and easy idea to test with!!!

I was able to engrave on a dark blue porcelain tile piece by using black tempura. I then grabbed a rock from the front yard area and briefly gave it a try. It took %100 which did indeed burn away material but it was a small area only. I’ll find a larger flat rock to try somewhere. The porcelain came out really nice in my simple power/speed tests so it is possible but I have doubts that a marker of this type would last out in the elements even when mortared to a solid brick or other mount. I’m not an expert on this.

Focus length is critical for this kind of etching. A flat rock will be easy to focus on, while most rocks will not be so easy due to natural variance of shape.

Hey Jim, My intent is to try to locate as flat stone as I can to try things on, then if I have any success then will look for polished stone or similar for a flat surface.

Before I got my fiber laser I did some engraving on glossy charcoal grey porcelain tile with my 10w diode machine, it was slow but I got about .7 mm deep. I then painted (white) the engraved lettering and graphics and when that was cured I scraped any excess slop off with a razor scraper.

The lady who was asking, has decided to go forward with a professional service for markers. But I’ll say, this was educational at a minimum for me. I very much appreciate everyone’s inputs.