newage

March 20, 2022, 8:50am

1

Hello!

Starting stream

ALARM:2

Grbl 1.1f [’$’ for help]

CNC4030|1.02|211109

[MSG:’$H’|’$X’ to unlock]

[MSG:Caution: Unlocked]

ok

A couple of things to look at:

Make sure that your GRBL settings $130, $131, $132 – [X,Y,Z] Max travel in mm is setup correctly.

Suggest you work in Absolute Coords mode in Start From: setting in Laser window until you’re very familiar with the laser.

That should avoid most of these situations going forward.

The other possibility is that your coordinates system is not getting properly setup after homing.

Can you confirm to what corner your laser homes?

What are the coordinates of the laser after homing?

Can you run these commands in Console after homing:

$$

$#

?

newage

March 20, 2022, 5:23pm

3

Hi!

here’s the result of $$:

$$

$0=10

$#

[G54:-300.000,-150.000,0.000]

?

<Idle|MPos:-1.000,-1.000,-1.000|FS:0,0|WCO:-300.000,-150.000,0.000>

ok

Did you set this deliberately? It doesn’t seem to be causing a problem at the moment. You may have set this up for CNC operation.

Can you confirm what your actual work area is for the laser? Is it actually 200x200x100mm?

newage:

<Idle|MPos:-1.000,-1.000,-1.000|FS:0,0|WCO:-300.000,-150.000,0.000>

You’re starting in negative coordinates. I think you may be able to fix this by adjusting your pull-off.

$27=2

newage:

$32=0

You’re not on laser mode which you almost certainly want:

$32=1

Can you try making those adjustments, re-run a homing cycle, and then rerun ? command after homing?

newage

March 20, 2022, 6:41pm

5

Hi!

$0=10

$#

?

However when I type G0 X0 Y0 it homes into the old position as shown in the photo.

Did you make a bunch of arbitrary changes?

Let’s fix these:

$20=1

$30=1000

$110=1200

$111=1200

$132=100

Also, you didn’t change your pull-off.

$27=2

Please fix and rerun.

Also, what is your actual work size please?

newage

March 20, 2022, 6:51pm

7

berainlb:

$27=2

Pull Off would not change:

Nothing in the GRBL changes should have changed homing direction. So not sure what you’re seeing. Also, G0 is not a homing command.

newage

March 20, 2022, 6:57pm

10

$27=2.000

error:3

Grbl ‘$’ system command was not recognized or supported.

What could be wrong?! Could be that I connected the switches wrong or something else, since the controller comes with no instructions.

Vendor may be preventing changes to that parameter.

Anyhow, starting from -1,-1 shouldn’t necessarily cause the error that you initially getting. I don’t think.

Under what circumstances did you get the error message?

And can you confirm your work area please?

newage

March 20, 2022, 7:03pm

12

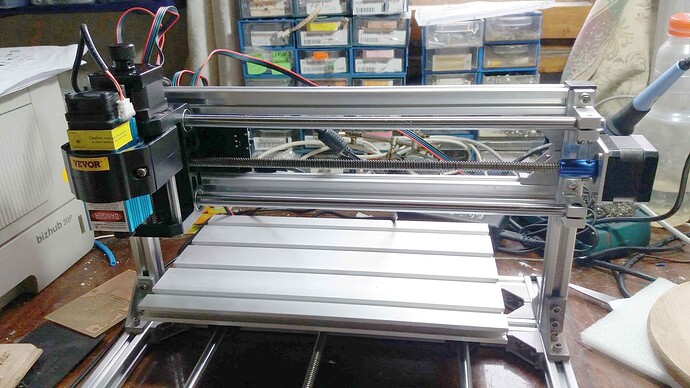

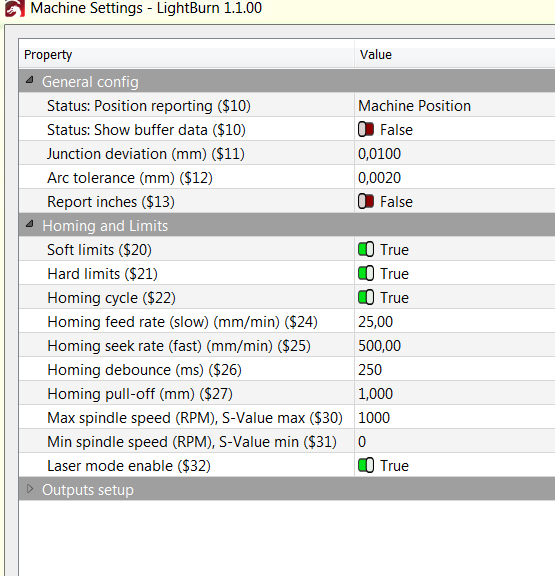

Here’s the machine settings menu:

according to specifications:

Effective Working Travel: 300(X)x180(Y)x45(Z)mm

Change these to:

$130=300

$131=180

$132=45

In Device Settings change work area to 300x180.

Rerun your original test and see if you still get the same error.

newage

March 20, 2022, 7:38pm

14

It seems to be working now.

newage

March 21, 2022, 12:47pm

15

Now I have the following problem:

On or near line 4:

[MSG:Caution: Unlocked]

ok

What does it mean?

Are you using Absolute Coords? If not, suggest you do so.

This occurs if the machine believes you are about to go beyond the borders of the laser and prevented a crash.

newage

March 21, 2022, 3:28pm

17

No, I tried to use “current position”. Isn’t it possible to use both?

It’s possible but you need to ensure you’re not running out the boundary. This means no manual moves after homing. Only jogging. And you need to make sure that the burn boundary still doesn’t go beyond the working area.

If you don’t want to deal with the error message you can disable soft-limits with $20=1 but you diminish some of the value in having homing switches and risk crashing.

newage

March 21, 2022, 5:11pm

19

Is it possible NOT TO home the Z (the laser) because I lose the focus and have to re-adjust it every time?

Only if you get a different firmware.

But why do you lose focus? Can you not set focus based on material thickness? Or specific a z offset for the layer.