So I have made this jig for engraving pucks and iv always though it was engraving accurately untill I recently when I needed to engrave something that required a decent amount of accuracy… Like a circle on a circular object ( sticks out like a sore thumb ) at first I thought that maybe some stuff got moved around on my jig so I cut another one but the problem has persisted , I tried enabling the cross hairs on my d1 to perhaps give me more accuracy but again no luck. I’m starting to think maybe my belts on machine need tensioning or the rails need lubrication? Any thoughts on this ? Maybe there is something in light burn I am missing ?

If you cut a card jig and then place your pucks on the jig your engraves are off?

How is your Origin set?

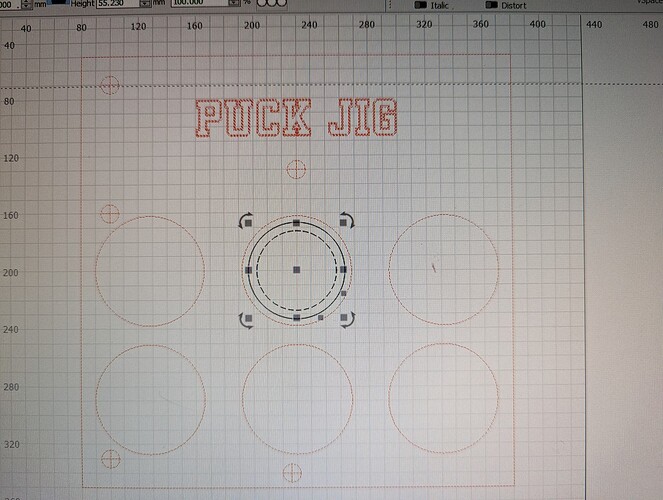

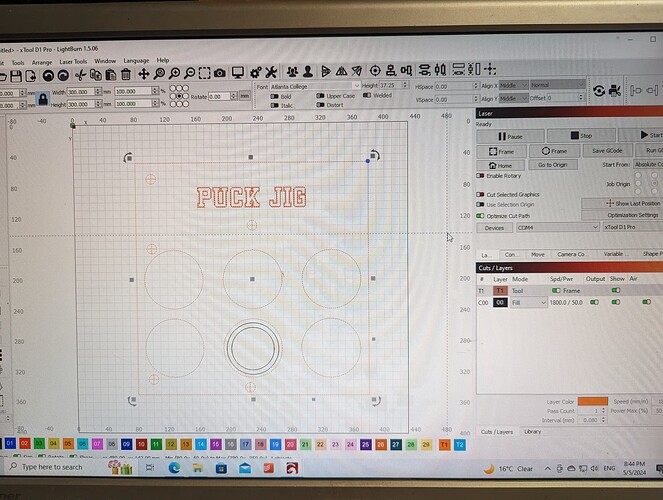

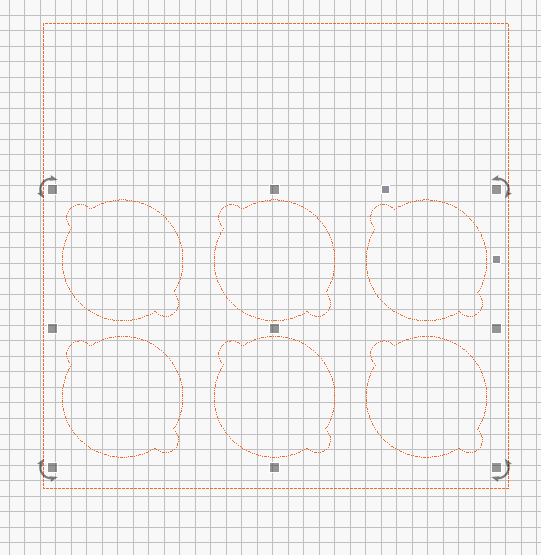

Can you post a screenshot of Lightburn with your jig selected?

Yes they are always off to the one side I can’t figure it out… I just ripped apart my laser, cleaned it , re lubed it and tensioned the belts with no luck. Origin is set to the center and I’m starting from absolute coords

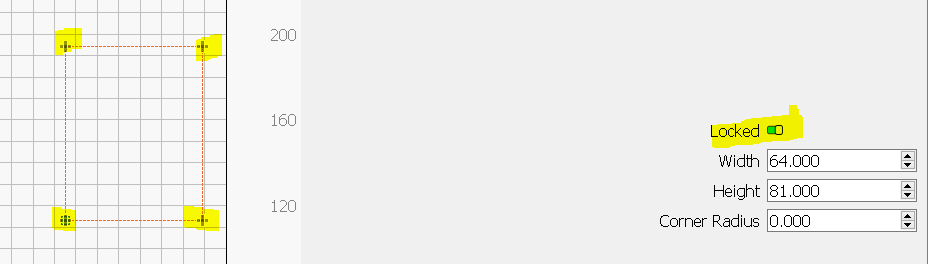

You need to register your jig on the bed and lock your shape In the Shape Properties window (notice the corners of the shape changes when locked)

Then cut your jig and save your file.

.

I didn’t learn much from those videos except how to make an array which is cool… it may help …

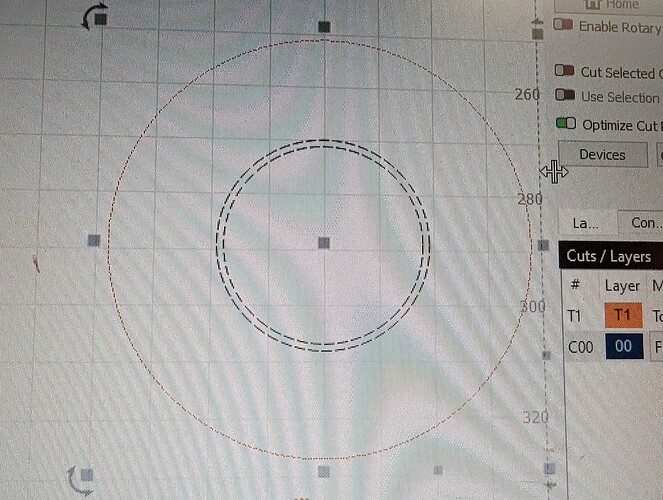

My circles are coming out weird now. Can you explain this ?

Sorry the “precision” video was this one.

Could you explain further how you setup your jig, start from origin, power speed settings?

Also these misalignments happens in every jobs?

Iv figured it out.

The circles being off was a setting I changed to get the cross hairs working.

The inaccuracies I was complaining about were because of the homing function.

I had this (now bad) habit of homing after I set my jig. Which took it out of position a mil or 2 every time. I really appreciate you helping me. I learned a number of new things from you coaching me here… Locking my jigs is invaluable!

This also gave me an excuse to get my machine out and give a once over which is Probley needed too. Lol

Anyways case closed ! The mystery has been solved !

I’m glad everything’s on track.

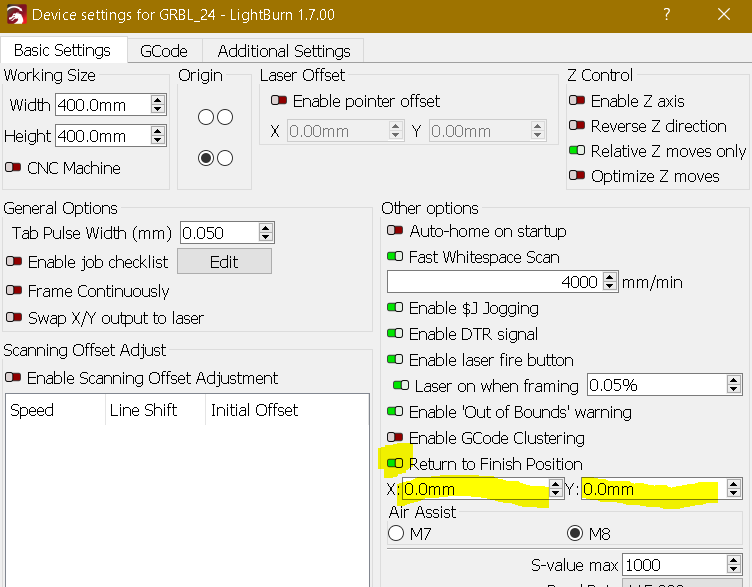

You could also enable an out of-the-way finish position (e.g. X=220 Y=40).

.

.

You could also make the jig out of ply or thicker cardboard to avoid random movements by using air-assist and vibrations of faster speeds and you can add some cuts to the jig to make it easier to remove the pucks.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.