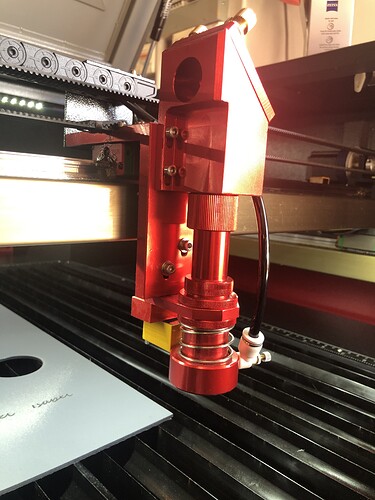

Hi everyone. I’m Running 150W laser, I’d love some help on changing this laser head, I’m hoping to run a 4” lens however I think the nozzle will be way too far from the work piece for the air assist to do anything. I’ve been looking at cloud Ray but I’m not really sure what I need or if I can modify my existing head. I’ve attached a photo of my current laser head.

Yeah, don’t see you putting a 4" in that narrow lens tube. As you increase your focal length, the lens moves up away from the nozzle tip. What diameter lens’ do you have? Do you care of you stay with that diameter?

Yeah it’s way too short to put a 4” in it, I’ve currently got a 20mm diam lens, i don’t think there’s enough room for it to move up higher. How do you think the best way to go about it is?

It looks like you have some sort of auto focus on there. What and how you make a head change will depend on how tied you are to the auto focus, and how it mounts, or what possible switch alternatives would work for your machine. Would need a more downward angle pic to give you any more direction. Any options from the manufacturer?

The autofocus is a proximity sensor that detects when the spring is pushed up and the metal goes in front of it. I don’t have a downward image at the moment but will take one when I’m back at the workshop tomorrow. I’m not too fussed about having the autofocus i wouldn’t mind changing it to the pen type either. Unfortunately there are no options from

The reseller here for changing the head and I’m not sure who the original manufacturer is in China.

With the Ruida controller, I’m pretty sure you could switch over to a pen style/ I had auto focus tunnel vision when I got my machine because it didn’t have it. But my machine also shipped with an engraving set up so I had 20mm or better between the work and the nozzle tip.

Once I switched to a cutting set up and got my nozzle down around 7mm from the work, it became unimportant. I cut primarily the same material, so for the most part I only move my bed a few mm. With a good adjustable head, I find myself adjusting the nozzle instead of the bed more and more.

With a 20mm lens, there is a good chance you have a nozzle with an M22 thread. Assuming you have the means to adjust your auto focus accordingly, you could simply get an extension tube to go in your existing nozzle and drop the 4" up at the top of the tube assembly.

If you do go the full head change, I would recommend either the complete C series head from Cloudray, or Russ’ MK2 lightweight aluminum head and the lower tube and nozzle for the C series. I make those two recommendations on a couple of factors. First off is I purchased the MK2 lightweight head and love it. You can see a pic on Russ’ YouTube videos, or my Google Mod Page. The second reason is that Russ is working on a long compound cutting arrangement based on the C series lens tube. If it works as it apears it will, it promises to give any laser a rough 50% or better boost in cutting ability. I’d really hate to be able to cut 50% thicker material

I guess I could just remove the bottom of the nozzle and add an extension to the tube on the bottom, I’ll have to check what the thread size is on the bottom of the nozzle in which case the autofocus would still work since it’ll push against the nozzle and still push the spring up to the proximity sensor.

I’m probably not going to be changing the entire laser head at this point but I definitely will in the future, would the C type laser head work well for both engraving and cutting, I’m guessing it would since it can take several focal lengths from what I’ve seen.

Cutting vs engraving is a combination of lens tube, nozzle, and air assist.

Engraving is the happy go lucky of the pair. As long as the beam hits the material and you have good exhaust, it’s perfectly happy to go zipping back and forth across your work. Doesn’t care if there’s 8mm or 20mm between the tip and the work. Air flow can be just enough to keep the lens clean.

Cutting is the very particular bugger. He wants GOOD air flow down close to the work. That means an unrestricted air fitting on the nozzle, and a tip to work gap of less than 10mm. If you are going to use a long focal length, that means a lens tube that can hold the lens up and away.

Any set up can engrave, you just turn the air flow down. With your machine being a 150W with a 20mm lens you are pretty much guaranteed to have a cutting configuration and a M22 nozzle thread.

Just about any good head arrangement that has a straight lower tube that can move the lens’ up the tube will due. I talk about the C series because that is the tube Russ designed the MK2 for. The only difference between the C and E series on the Cloudray web site is the OD of the tube. All the ID arrangements are the same between them. If your factory head assembly happened to have an upper that would accept a full size lower tube but did not have a position for the 4" lens, you would simply swap the lower tube for the appropriate sized C or E lower tube and be on your merry way.

My 80w red&black came with an engraving head and it quite sucks for cutting thick material. I can run up to a 2-1/2" lens but it puts the nozzle way the hell far from the material. I get by because I’ve got a fat air compressor and put a huge amount of air through the nozzle. (I’m surprised I haven’t blown a lens back up the tube yet!)

I’ve ordered a complete Cloudray “C” type head and it was allegedly shipped a week ago but it appears to be stalled in china and who knows when it will ever get here…

My 80W was the same. I went through a few variations before breaking down and buying Russ’ MK2 lightweight aluminum head. His slider wouldn’t work for my machine, but he was kind enough to send me his dxf file, and I was able to adapt it to my machine. You can see pics of it on my Google Mod Page.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.