Hi! My makerspace has spent the last two years rebuilding the control system on a 100x50 circa-2000 Kern laser system. (Basically by installing a Ruida controller to make it look like the smaller RabbitUSA lasers we already have.

The good news is that we have got it into runnable condition. Right now, we are trying to characterize its function, or put another way, see what this thing is capable of.

It has a Coherent RF-modulated laser package on it, and measurements show that we are getting the full 150 watts out of it. Being optomistic, we’ve thrown several chunks of 3/4" wood at it, and we’re getting results we don’t understand. We have a REAL hard time getting through even some relatively soft cypress.

What we do see is that if we make multiple passes, we get closer and closer to burning through, but not -quite- there. (5 passes at 15 mm/sec 95% power)

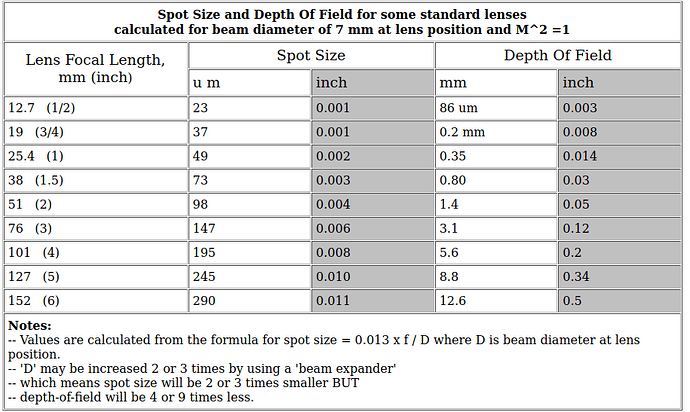

So, right now we don’t really know what variables may be affecting this. We have a Kern focusing lens in place, LPZ-0715-ET.20. .75" diam, .0" ET, EFL= 1.5" at 10.6 um. We understand those terms, but not what they might MEAN.

We do have some folks who are wondering whether we should boost the pressure and/or volume of our air purge. But that’s another hunk of uninformed guesswork.

Any suggestions would be profoundly appreciated.