I have a 100 watt Red Dragon RDL6040 that came with a 63mm focus lens. I also ordered a shorter focal length lens at 50mm. Red dragon say just replace the 63mm lens form the 50mm in the laser head and all will be fine. Yet on line I can see laser heads all stating the focal length. Do I need another tube of different length to change between lenses? What if I wanted a 103mm lens?

Regards

Mick

Do a ramp test to find it’s focal point… You should do this when you change optics in the path to ensure it’s properly operating.

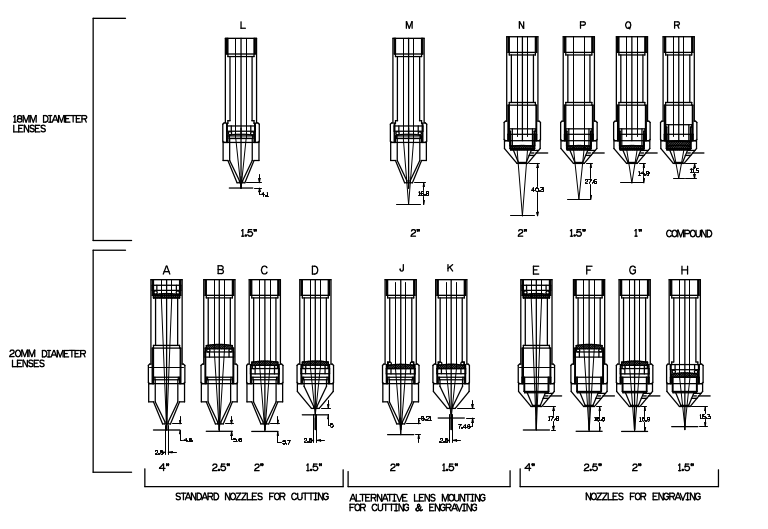

With lenses, tubes and nozzles there are a few things to keep in mind.

Notice where the lens actually is, nozzle configuration, the distance from the material and the intended purpose. The lens must have ‘room’ to get through the nozzle outlet. Long lens the focus far from the object will have a bigger beam, growing smaller as it reaches the material. There nozzle must have a ‘hole’ large enough to accommodate this.

These tubes can be ‘flipped’ over to change lens position…

These are ‘c’ series lenses/tubes but hopefully it will help better than me trying to explain it.

I am lacking the 2.5" lens, but have the rest of them.

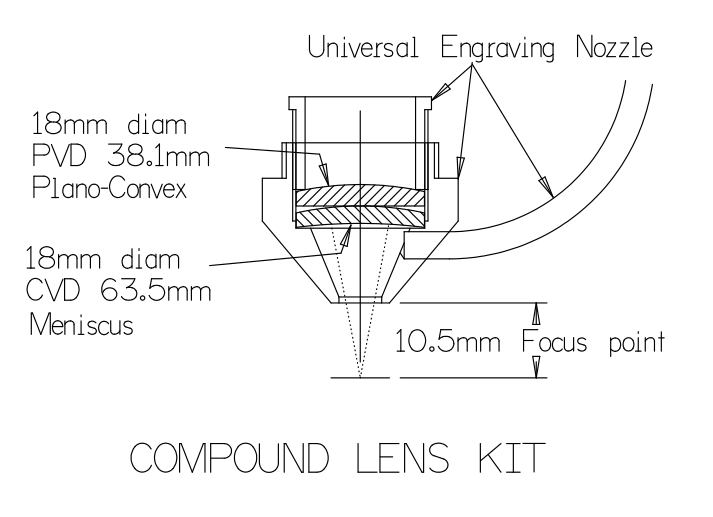

If you want the ‘best dot’ lens, for engraving the compound lens is probably the best choice, if you can fit it in your system…

I have my lenses in separate tubes and nozzles.

![]()

Thanks Jack

I appreciate your reply… I guess what you are saying is yes, you will need to have the appropriate Laser Head to accommodate the differing lenses.

Here are a couple things to keep in mind. The laser beam that bounces off the mirrors is pretty much a constant diameter. The purpose of the lens is to concentrate that energy into a very small dot. The purpose of the tube is to hold the lens and the nozzle. The nozzle is important because pressurized air inside the nozzle rushes out the hole and helps the beam cut and also blows smoke out of the way. So the lens is held as some focal distance from the work and the air has to make it into the cut. Farther the focal length the more difficult it is for the air to hit the cut with any volume. Also the beam might be wide at that point so the hole in the nozzle might be bigger.

So its preferred to have a lens tube for every lens. However long lenses with the lens stuffed way up inside the tube is not ideal. Just my opinion. So on my long lens I mounted it at the end and skipped the nozzle and just direct the air down on the cut.

Most of these machines are low cost, so they don’t target a wide variety of things like tube/lenses.

Just keep your eye open as there are options that creep up… The more you know the better… and the better decisions you make.

Take care

![]()

In most cases, a 2" lens is best all-around.

The beam leaves the lens at about the same diameter it enters, and converges 2" down. A 2D section of that is a triangle. We don’t want that triangle to clip on the air assist cone orifice. The more clearance there is between the focal point and the cone, the larger that orifice needs to be which can make for bad airflow.

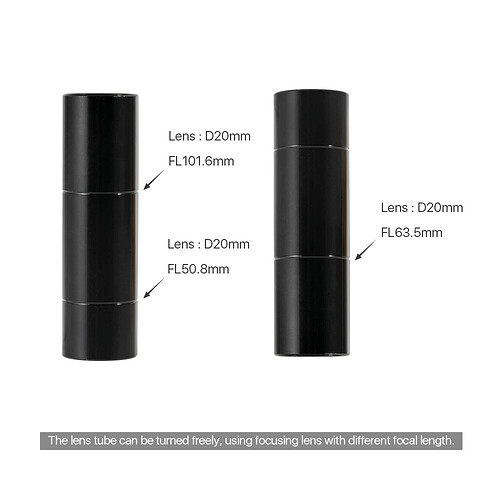

The necessary relationship is just trigonometry of beam diameter, focal distance, and orifice size and placement. When we change lenses to a different focal length, usually we still use the same nozzle orifice size, but either place the lens higher or lower in the tube or use a tube of a different length that places the nozzle orifice further or closer to the lens.

Since we’re just looking at the beam forming a cone (triangle on 2D model), you can see how the laser’s spot widens when you get out of focus. Like warped material. A longer lens with the same beam diameter is a more acute triangle, and less affected when the cutting height varies from the perfect focus. i.e. it has a greater “depth of focus”.

However, there’s a cost- for reasons that are all “crazy physics stuff”, the minimum spot size at perfect focus actually scales with the RECIPROCAL of the focal length. Going from a 2" lens to a 4" lens doubles the diameter of the focal point, reducing its energy density by a factor of 4x. Also since it’s a larger diameter, it’s a larger kerf, and can’t engrave fine detail.

For fine detail, or where we have to have high energy density on a very flat, thin surface like burning off anodization from aluminum, we can use a 1.5", 1" lens- or, this compound engraving lens is a CRAZY 10.5mm, it will produce a radically more intense focal point, 23x the energy density!

However, the cost is a reduced depth of focus. These have to be at the PERFECT focal point, and must be very flat. These are terrible at cutting anything that’s not very thin. Also, high resolution engraving with a finer focal point means the line interval must also be scaled down- which scales up the runtime for a given area of work.